Dec . 06, 2024 08:13 Back to list

Products for Square Root Differential Pressure Gauge Measurement Solutions

Understanding Square Root Differential Pressure Gauge Products

In various industrial applications, the need for accurate measurement of differential pressure is paramount. Differential pressure gauges are critical components in systems dealing with fluids, gases, and other media, and they play a vital role in ensuring that processes run smoothly and efficiently. Among the many types of differential pressure measuring instruments, square root differential pressure gauges have gained prominence for their unique benefits. This article will explore what square root differential pressure gauges are, their functionality, applications, and the benefits they bring to various industries.

What is a Square Root Differential Pressure Gauge?

A square root differential pressure gauge is a specialized instrument designed to measure the differential pressure across a flow element such as an orifice plate, venturi, or nozzle. The fundamental principle of operation relies on the square root relationship between the differential pressure and the flow rate. This means that the flow rate is proportional to the square root of the differential pressure. Therefore, if you know the differential pressure, you can calculate the flow rate by taking the square root of that measurement.

The square root relationship is particularly useful because it allows for a linear output when calibrated correctly, which simplifies the reading and interpretation of flow rates. This is one of the key advantages of using square root differential pressure gauges, especially in applications that require real-time monitoring of flow conditions.

How Does It Work?

The operation of a square root differential pressure gauge is relatively straightforward. The gauge consists of a sensing element that measures the pressure difference between two points in a system. This differential pressure is then converted into an electrical signal, usually through a transducer. The output is then processed to provide a linear measurement corresponding to the flow rate.

To illustrate, consider a scenario involving fluid flow through a pipe. An orifice plate is installed to create a pressure differential. As the flow increases, the differential pressure across the orifice plate increases, resulting in a higher gauge reading. By utilizing the square root function, the gauge translates this measurement into an accurate flow rate, allowing operators to make informed decisions based on up-to-date information.

Applications of Square Root Differential Pressure Gauges

Square root differential pressure gauges are widely used across several industries, including

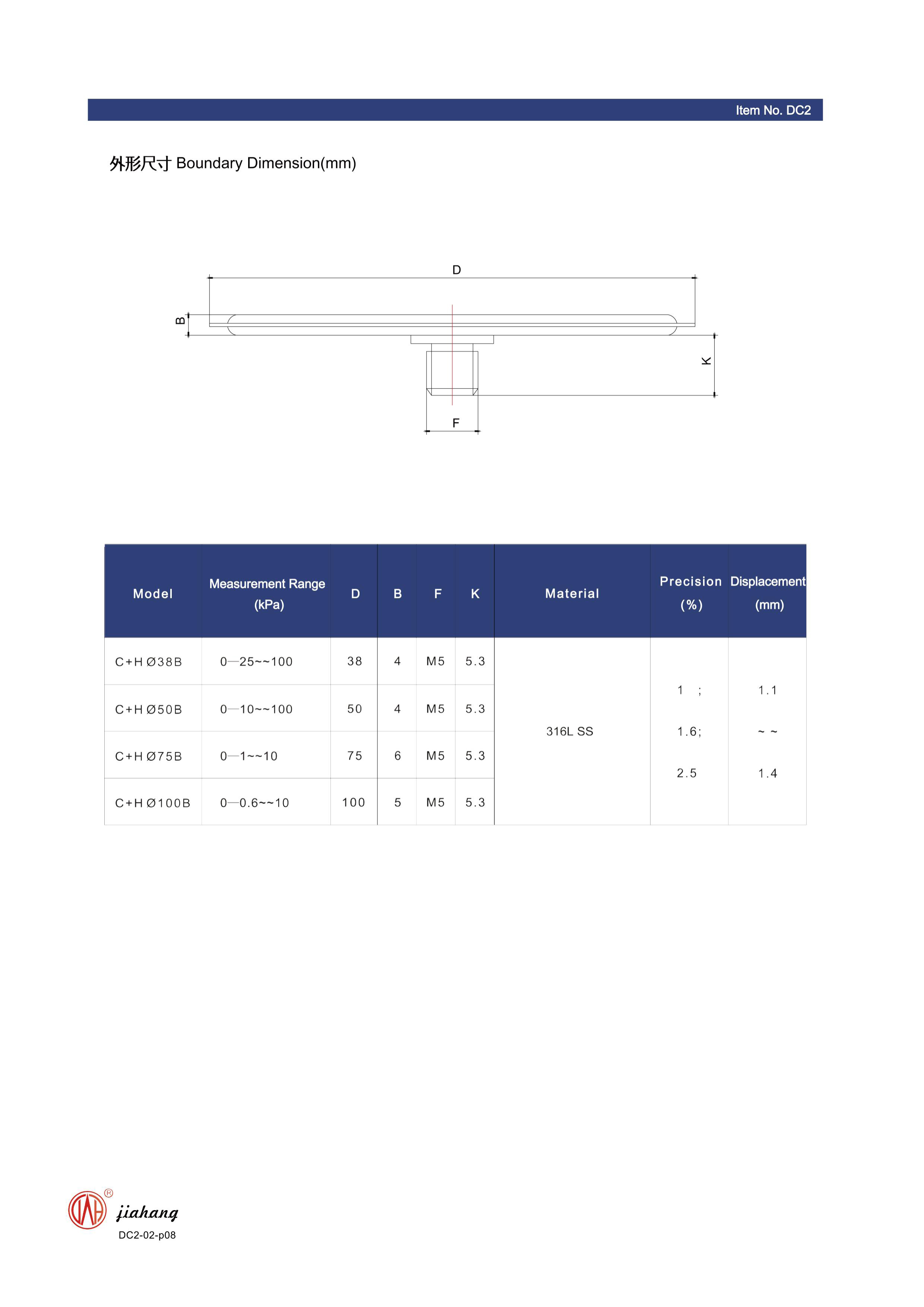

square root differential pressure gauge products

1. Water and Wastewater Treatment Monitoring flow rates in treatment plants is crucial for maintaining operational efficiency. Square root differential pressure gauges help in measuring flows for chemical dosing and ensuring optimal treatment processes.

2. Oil and Gas The exploration and production of oil and natural gas rely on precise flow measurements. These gauges can be used to monitor flow rates in pipelines, separators, and other critical components.

3. HVAC Systems In heating, ventilation, and air conditioning systems, maintaining precise airflow is essential for comfort and energy efficiency. Square root differential pressure gauges are used to monitor duct pressures and airflow rates.

4. Pharmaceuticals Compliance with stringent regulations means that flow rates in pharmaceutical manufacturing must be meticulously monitored. These gauges ensure accurate readings, contributing to product quality and safety.

5. Food and Beverage Many processing lines in the food industry require careful monitoring of flow rates to ensure consistency and quality in production. Square root differential pressure gauges are instrumental in these systems.

Advantages of Square Root Differential Pressure Gauges

The benefits of square root differential pressure gauges include

- Accuracy Their design allows for high accuracy in flow measurement, essential for process control and monitoring. - Simplicity The conversion of differential pressure to flow rate through a square root function provides straightforward readings for operators. - Reliability These gauges are known for their durability and longevity, even in harsh industrial environments. - Cost-effectiveness Given their efficiency, they contribute to reduced operational costs and improved energy efficiency.

Conclusion

Square root differential pressure gauges are a vital tool in various industries, providing crucial measurements that allow for optimized process control and enhanced operational efficiency. Their ability to relate differential pressure to flow rate in a linear manner makes them indispensable in settings where accurate flow measurement is necessary. As industries continue to evolve and seek greater efficiency, the role of these gauges will remain significant, underpinning the integrity and reliability of countless systems.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025