Dec . 13, 2024 21:53 Back to list

Suppliers of Spring Diaphragm Pressure Gauges for Accurate Measurement Solutions

The Role of Spring Diaphragm Pressure Gauges A Comprehensive Overview

Pressure measurement is a critical aspect of various industrial processes, and among the devices employed to achieve this, spring diaphragm pressure gauges stand out for their reliability and accuracy. These gauges are widely used across different sectors, such as oil and gas, manufacturing, and water management. As industries continue to prioritize efficiency and safety, understanding the importance of selecting the right pressure gauge suppliers becomes paramount.

What is a Spring Diaphragm Pressure Gauge?

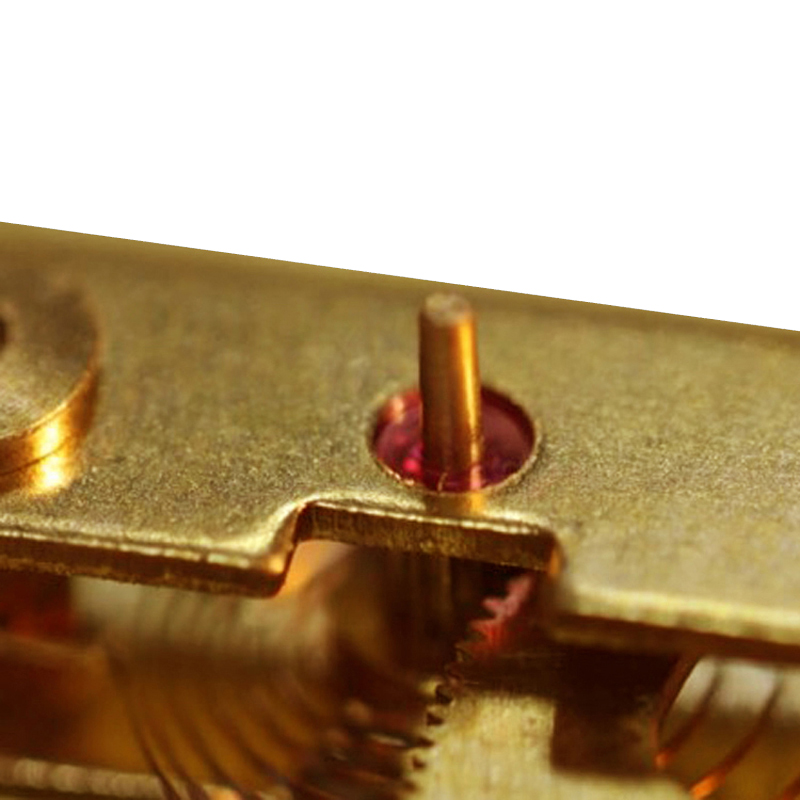

A spring diaphragm pressure gauge is a type of mechanical pressure gauge that utilizes a flexible diaphragm as its sensing element. When pressure is exerted onto the diaphragm, it flexes, resulting in a displacement that is primarily translated into a readable pressure measurement via a needle on a dial. This mechanism allows for precise pressure readings in applications where measurement accuracy is crucial.

The design of spring diaphragm pressure gauges ensures that they can handle high pressures and offer enhanced durability. They can also be calibrated for both absolute and gauge pressure readings, providing versatility across various operational environments.

Advantages of Spring Diaphragm Pressure Gauges

1. High Accuracy One of the most significant advantages of spring diaphragm pressure gauges is their high level of accuracy. They can measure pressures within a very tight tolerance range, making them suitable for critical applications where precision is non-negotiable.

2. Robust and Durable Spring diaphragm gauges are built to withstand harsh operating conditions. Their robust construction allows them to endure vibrations, shocks, and extreme temperatures, which are common in industrial settings.

3. Wide Range of Applications These pressure gauges are versatile and can be used in numerous fields, including chemical processing, water treatment, and HVAC systems, among others. They are ideal for both high and low-pressure applications.

4. Ease of Installation and Maintenance Spring diaphragm pressure gauges are relatively easy to install and maintain. Their straightforward design helps reduce downtime resulting from maintenance activities, ensuring continuous and reliable operation.

5. Cost-Effective Given their reliability and lifespan, these gauges can be cost-effective in the long run, providing a good return on investment for companies looking to optimize their operations.

spring diaphragm pressure gauge suppliers

Selecting the Right Supplier

Choosing a reliable supplier for spring diaphragm pressure gauges is essential for ensuring quality and performance. Here are some factors to consider when selecting a supplier

1. Experience and Reputation A supplier with a proven track record and positive reviews from previous customers is more likely to provide high-quality products.

2. Product Range Look for suppliers that offer a comprehensive range of pressure gauges. This flexibility allows you to find a product that meets your specific needs.

3. Quality Assurance Ensure that the supplier adheres to stringent quality control standards. Certifications such as ISO groups indicate a commitment to maintaining high-quality manufacturing processes.

4. Technical Support A good supplier should provide robust technical support, helping clients with product selection, installation, and maintenance queries.

5. Pricing While cost should not be the only determining factor, it is essential to find a supplier that offers competitive pricing without compromising on quality.

6. Warranty and After-sales Support Reliable warranties and after-sales support services indicate a supplier's confidence in their products and enhance customer satisfaction.

Conclusion

In conclusion, spring diaphragm pressure gauges are essential instruments in monitoring and controlling pressure in industrial applications. Their accuracy, durability, and versatility make them a popular choice among engineers and operators alike. When seeking to invest in pressure measurement technology, it is crucial to partner with experienced and reputable suppliers to ensure that you receive high-quality products that meet your operational needs. Whether in a manufacturing plant, laboratory, or any other environment requiring precise pressure monitoring, choosing the right spring diaphragm pressure gauge will positively impact both safety and efficiency in operations. Thus, investing time to evaluate suppliers will undoubtedly lead to better outcomes in your pressure measurement endeavors.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025