Jul . 12, 2024 05:40 Back to list

Service for diaphragm type pressure gauges maintenance, calibration, and repair services.

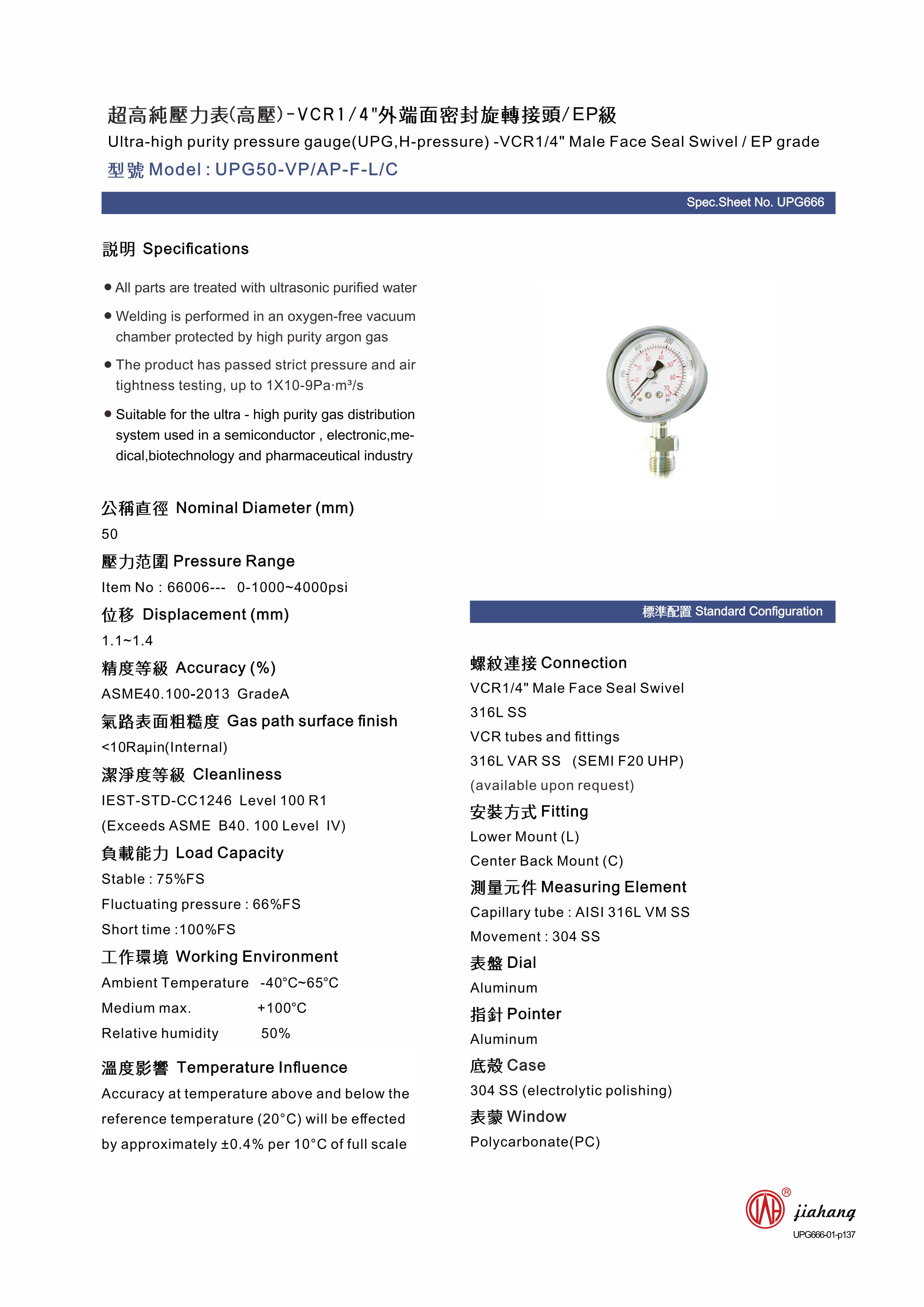

Diaphragm type pressure gauge is a common device used to measure and display pressure in a variety of applications. This type of pressure gauge relies on a diaphragm, a flexible membrane that deforms in response to changes in pressure, to provide an accurate reading. Diaphragm type pressure gauges are widely used in industries such as oil and gas, chemical manufacturing, and pharmaceuticals.

One of the key advantages of diaphragm type pressure gauges is their ability to accurately measure pressure in harsh or aggressive environments. The diaphragm acts as a barrier between the pressure medium and the internal components of the gauge, preventing damage or corrosion. This makes diaphragm type pressure gauges particularly well-suited for use in applications where the pressure medium is corrosive, abrasive, or otherwise potentially harmful.

Diaphragm type pressure gauges require regular service and maintenance to ensure accurate and reliable operation. One important aspect of servicing a diaphragm type pressure gauge is to periodically check and calibrate the gauge to ensure that it is providing accurate readings. This can be done using a known pressure source or a calibration device specifically designed for pressure gauges

diaphragm type pressure gauge service. Another important aspect of servicing a diaphragm type pressure gauge is to regularly inspect the diaphragm for signs of wear or damage. Over time, the diaphragm can become worn or weakened, leading to inaccurate readings or potential failure. If any issues are found during the inspection, the diaphragm should be replaced promptly to prevent further damage to the gauge. In addition to regular maintenance, diaphragm type pressure gauges should also be installed and used according to the manufacturer's recommendations. This includes ensuring that the gauge is properly mounted and connected to the pressure source, and that the pressure medium is compatible with the materials used in the gauge. Overall, diaphragm type pressure gauges are reliable and accurate devices for measuring pressure in a variety of applications. By following proper maintenance procedures and servicing the gauge as needed, users can ensure that their diaphragm type pressure gauge remains in good working condition and provides accurate readings for years to come.

diaphragm type pressure gauge service. Another important aspect of servicing a diaphragm type pressure gauge is to regularly inspect the diaphragm for signs of wear or damage. Over time, the diaphragm can become worn or weakened, leading to inaccurate readings or potential failure. If any issues are found during the inspection, the diaphragm should be replaced promptly to prevent further damage to the gauge. In addition to regular maintenance, diaphragm type pressure gauges should also be installed and used according to the manufacturer's recommendations. This includes ensuring that the gauge is properly mounted and connected to the pressure source, and that the pressure medium is compatible with the materials used in the gauge. Overall, diaphragm type pressure gauges are reliable and accurate devices for measuring pressure in a variety of applications. By following proper maintenance procedures and servicing the gauge as needed, users can ensure that their diaphragm type pressure gauge remains in good working condition and provides accurate readings for years to come.

Share

Latest news

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025