Nov . 06, 2024 12:04 Back to list

Sealed Diaphragm Pressure Gauge Applications and Benefits in Various Industries

Understanding Sealed Diaphragm Pressure Gauges A Comprehensive Overview

Sealed diaphragm pressure gauges are essential instruments widely utilized in various industrial applications to measure pressure in fluids and gases. These gauges combine accuracy, durability, and versatility, making them a popular choice in settings ranging from oil and gas to food processing.

What is a Sealed Diaphragm Pressure Gauge?

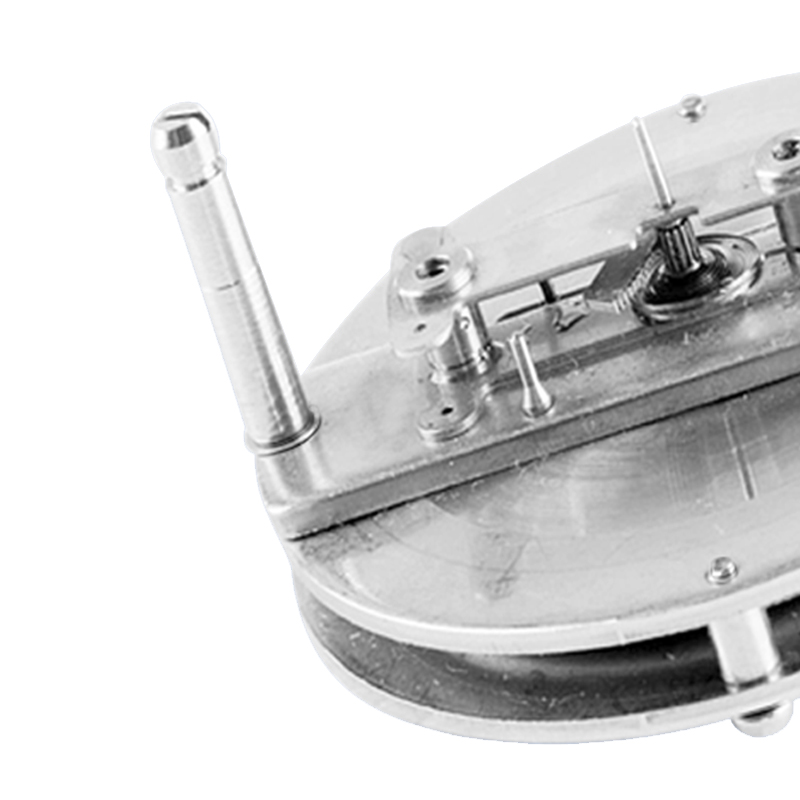

At the core of a sealed diaphragm pressure gauge is a flexible diaphragm. This diaphragm separates two chambers one exposed to the pressure of the fluid or gas being measured, and the other sealed and typically filled with a liquid or gas for protection. When pressure is applied to the diaphragm, it deforms, causing the movement of a pointer or a digital sensor that indicates the pressure reading on a dial or display.

The sealing of the diaphragm is crucial for preventing the ingress of contaminants that could affect performance or lead to corrosion. This feature makes sealed diaphragm gauges highly reliable in harsh environments, where exposure to moisture, dust, or corrosive materials is common.

Advantages of Sealed Diaphragm Pressure Gauges

1. Protection Against Contaminants The sealed design protects the internal mechanisms from particulates and liquids, ensuring longevity and accuracy.

2. Wide Range of Applications These gauges can be used for various media, making them suitable for liquid, gas, and even viscous substances. The ability to handle different pressures (both high and low) further enhances their applicability.

3. Accuracy and Sensitivity Sealed diaphragm gauges often provide high accuracy readings due to their sensitive design. This accuracy is vital for processes where precise pressure measurements are necessary.

4. Low Maintenance Because of their sealed nature, these gauges generally require less maintenance than open models. This can lead to cost savings over time, as there is less need for frequent calibration or replacement.

sealed diaphragm pressure gauge jah

5. Versatility in Mounting and Installation Sealed diaphragm gauges are available in various styles and mounting options, including panel, surface, or remote installations. This flexibility allows for integration into different systems seamlessly.

Applications

Sealed diaphragm pressure gauges find applications across a broad spectrum of industries

- Oil and Gas They are used to monitor pressures in pipelines and drilling operations, ensuring safety and efficiency. - Food and Beverage In this sector, maintaining the correct pressure is crucial for quality control and safety. Sealed gauges help protect against contamination. - Pharmaceuticals Accurate pressure monitoring is critical in the manufacturing of medications, requiring precise measurements to adhere to strict regulations. - HVAC Systems In heating, ventilation, and air conditioning applications, these gauges are employed to maintain optimal pressure levels, ensuring system efficiency.

Challenges and Considerations

However, sealed diaphragm pressure gauges are not without challenges. The choice of fill fluid is essential, as it can impact the gauge’s performance and response time. Additionally, while they are robust, extreme pressures or temperatures can exceed the design limits, causing gauge failure.

Regular calibration ensures that the gauges maintain their accuracy over time and can adapt to changing conditions.

Conclusion

In summary, sealed diaphragm pressure gauges play a critical role in numerous industries by providing reliable and accurate pressure readings. Their sealed design enhances durability and performance, making them indispensable tools in the quest for operational efficiency and safety. Industries that prioritize precision and reliability will continue to benefit from the unique capabilities offered by these sophisticated instruments, underscoring their significance in modern technology and manufacturing processes.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025