Dec . 18, 2024 07:36 Back to list

sealed diaphragm pressure gauge

Sealed Diaphragm Pressure Gauge An Overview

Pressure measurement is a crucial aspect of various industries, including manufacturing, oil and gas, chemical processing, and water treatment. Accurate and reliable pressure gauges are essential tools for these sectors, ensuring safe and efficient operations. Among the various types of pressure gauges available, the sealed diaphragm pressure gauge stands out due to its unique design and functionality. This article delves into the features, applications, and advantages of sealed diaphragm pressure gauges, providing a comprehensive understanding of their importance in pressure measurement.

What is a Sealed Diaphragm Pressure Gauge?

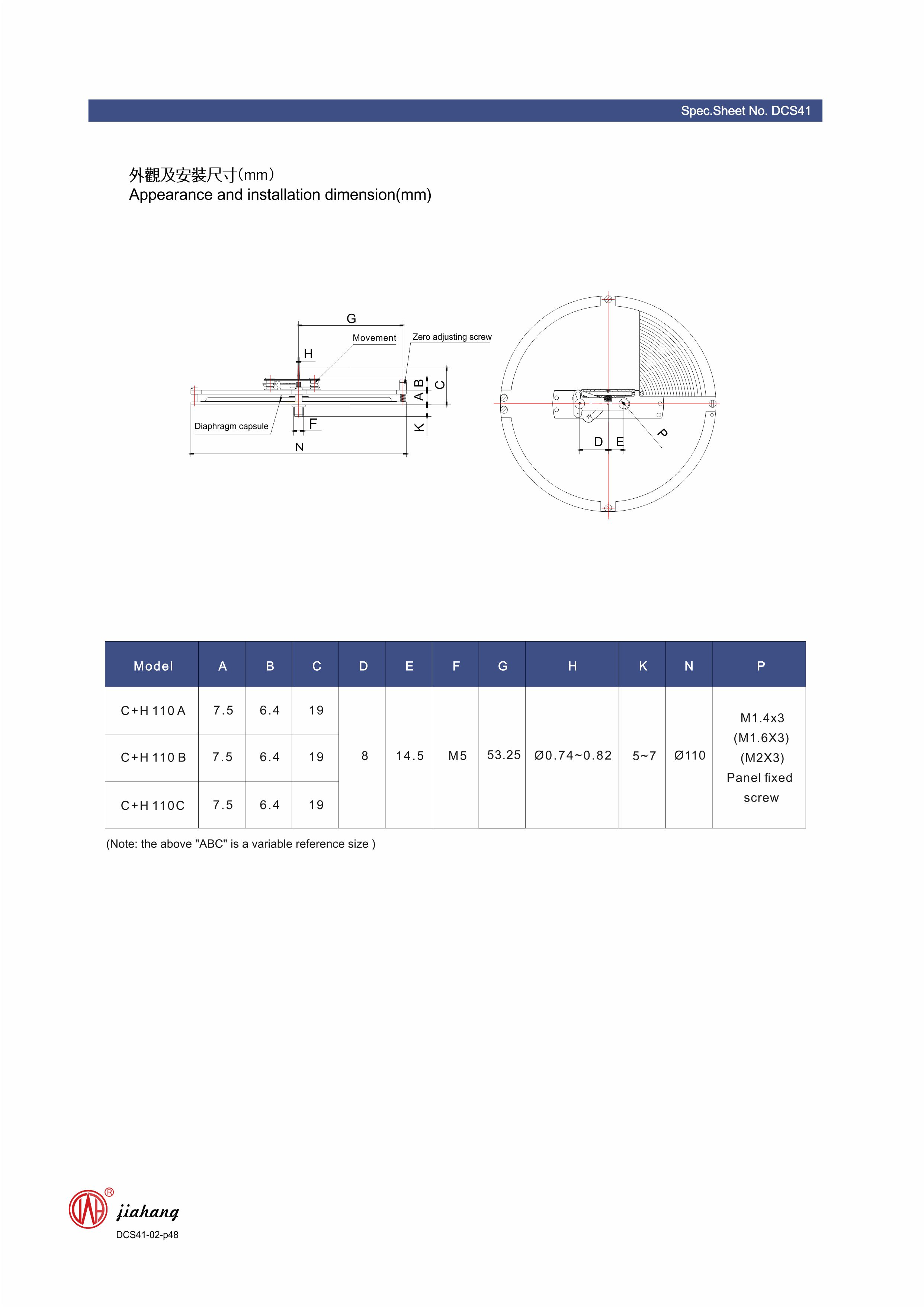

A sealed diaphragm pressure gauge is a specific type of pressure gauge that utilizes a flexible diaphragm to measure pressure. The diaphragm is a thin membrane made from materials such as stainless steel, which separates the measured medium from the measuring system. Unlike traditional gauges that are exposed to the process fluid, sealed diaphragm gauges are designed to be isolated, making them ideal for measuring corrosive, viscous, or contaminated fluids.

When pressure is applied to the diaphragm, it bends, causing a change in position that is transmitted to a mechanical or electronic indicator. This movement is then translated into a pressure reading on the gauge. The sealed design enhances the durability and longevity of the gauge, as it protects sensitive components from the harmful effects of aggressive media.

Applications of Sealed Diaphragm Pressure Gauges

Sealed diaphragm pressure gauges are widely used in various applications, especially in environments where traditional gauges would fail due to corrosion or other adverse conditions. Some of the key applications include

1. Chemical Processing In chemical production, the pressure of reactive and corrosive substances needs to be monitored accurately. Sealed diaphragm gauges prevent contamination and ensure safety.

2. Food and Beverage The food industry requires sanitary conditions to maintain quality and safety. These gauges are often used to monitor pressures in food processing pipelines, ensuring compliance with health standards.

3. Pharmaceuticals Similar to the food industry, pharmaceuticals require strict hygiene. Sealed diaphragm gauges provide a sterile environment, essential for accurate pressure measurement in drug production.

4. Oil and Gas In the oil and gas sector, measuring pressure in pipelines is critical. Sealed diaphragm gauges handle high pressures and can work in challenging environments, making them ideal for this application.

sealed diaphragm pressure gauge

5. Water Treatment Water treatment facilities use sealed diaphragm gauges to monitor pressures in various stages of the treatment process, ensuring efficient operations and compliance with safety regulations.

Advantages of Sealed Diaphragm Pressure Gauges

The popularity of sealed diaphragm pressure gauges can be attributed to several advantages they offer

1. Protection from Contamination The sealed design prevents process media from contacting the internal gauge components, significantly reducing the risk of contamination and ensuring measurement accuracy over time.

2. Durability and Longevity These gauges are built to withstand harsh conditions, including extreme temperatures and corrosive environments. This durability leads to prolonged service life, reducing the need for frequent replacements.

3. Accuracy Sealed diaphragm pressure gauges maintain accuracy even under varying pressure conditions. This reliability is vital for industries where precise measurements are critical.

4. Easy Maintenance With fewer components exposed to process fluids, maintenance and cleaning of sealed diaphragm gauges are simplified, contributing to reduced downtime and operational costs.

5. Versatility These gauges can be customized to suit various applications, including different pressure ranges and chemical compatibilities, making them a flexible solution for multiple industries.

Conclusion

In summary, sealed diaphragm pressure gauges play a pivotal role in accurate pressure measurement across various industrial applications. Their unique design, which isolates the measuring system from the process medium, allows them to excel in environments that challenge traditional pressure gauges. With their numerous advantages, including contamination protection, durability, and accuracy, it is clear why they are widely adopted across industries that prioritize safety and precision in pressure measurement. As technology advances, these gauges will continue to evolve, further enhancing their importance in modern industrial processes.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025