Sep . 22, 2024 05:30 Back to list

sanitary differential pressure gauge

Understanding Sanitary Differential Pressure Gauges

In many industries, particularly in food and pharmaceuticals, maintaining cleanliness and precision is paramount. This is where sanitary differential pressure gauges come into play. These specialized instruments are designed to measure the difference in pressure between two points in a system while ensuring compliance with stringent hygiene standards.

What is a Sanitary Differential Pressure Gauge?

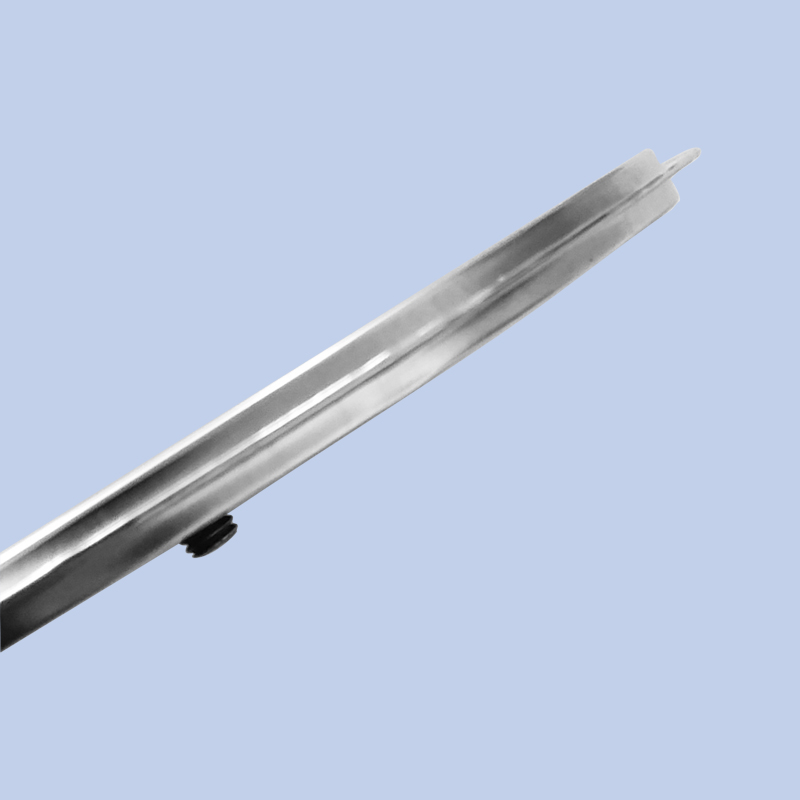

A sanitary differential pressure gauge is a type of pressure measurement device that is primarily used to monitor clean processes involving liquids, gases, or vapors. These gauges are constructed from materials that can withstand rigorous cleaning and sterilization processes, such as stainless steel, ensuring they remain free from contaminants. Their design typically includes sanitary connections, enabling smooth integration into piping systems without compromising the cleanliness of the contents they measure.

Importance in Industries

In sectors like food processing and pharmaceuticals, any contamination can lead to compromised product quality and safety. Sanitary differential pressure gauges ensure that the pressure differences across filters, valves, or other equipment are accurately monitored. This is crucial for applications such as filtration processes, where tracking the pressure drop across a filter can indicate when it needs to be cleaned or replaced, preventing potential blockages and ensuring consistent production quality.

Furthermore, these gauges play an important role in controlling levels of liquids in tanks and maintaining optimal conditions in various processes. Accurate pressure readings help operators adjust system parameters effectively, leading to enhanced quality control and operational efficiency.

sanitary differential pressure gauge

Key Features

Sanitary differential pressure gauges come with several features tailored to meet industry standards. First and foremost, they are designed for easy cleaning, incorporating smooth surfaces without crevices where bacteria can thrive. Many models also feature tri-clamp fittings for quick assembly and disassembly, facilitating regular maintenance.

Additionally, these gauges often include advanced technologies such as digital displays and remote monitoring capabilities. This allows for real-time data access and alerts, helping operators respond swiftly to any anomalies that could indicate a problem in the system.

Selecting the Right Gauge

When selecting a sanitary differential pressure gauge, it is important to consider factors such as the operating range, compatibility with the fluid being measured, and the environmental conditions. It is also crucial to ensure that the gauge meets relevant sanitary standards, such as those set by the FDA or 3-A Sanitary Standards.

Conclusion

Sanitary differential pressure gauges are essential tools in industries that prioritize safety and hygiene. By accurately monitoring pressure differences in various processes, these gauges help ensure product integrity, optimize operational efficiency, and maintain compliance with health regulations. As industries continue to evolve, the role of these gauges will only become more critical in achieving high standards of cleanliness and efficiency.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025