Nov . 21, 2024 20:58 Back to list

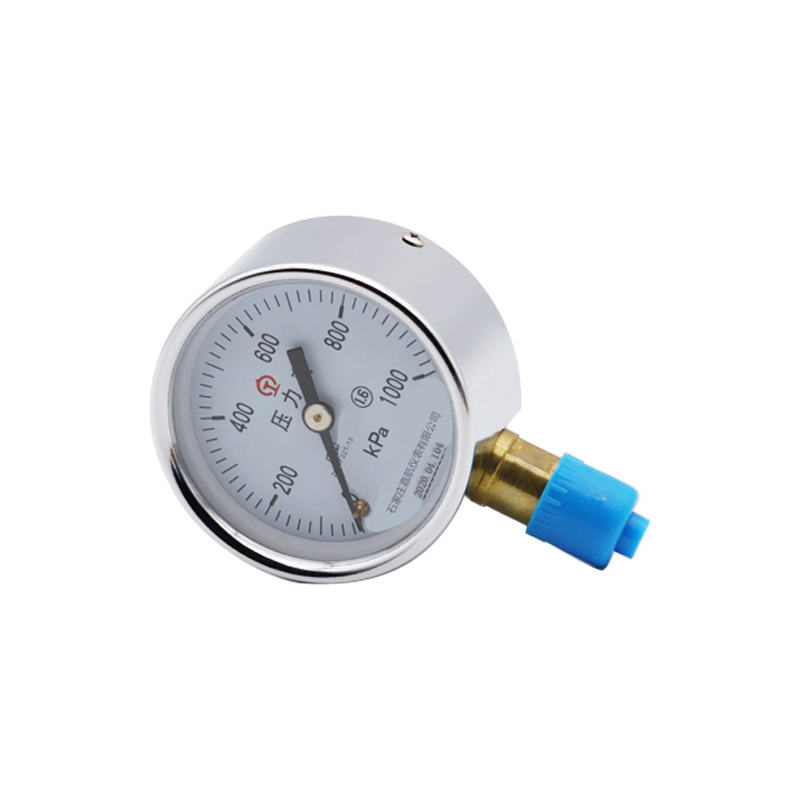

refrigeration differential pressure gauge products

Understanding Refrigeration Differential Pressure Gauge Products

In the world of refrigeration, maintaining optimal performance is crucial for energy efficiency and operational reliability. One of the key instruments that play a significant role in monitoring and maintaining these systems is the differential pressure gauge. This article delves into the importance of refrigeration differential pressure gauges, their functionality, and the variety of products available on the market.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument used to measure the difference in pressure between two points in a system. This measurement is particularly important in refrigeration applications, where pressure differences can indicate the overall health and efficiency of the system. This device is often used to monitor filters, fans, compressors, and evaporators within refrigeration cycles.

Importance of Monitoring Differential Pressure

Monitoring differential pressure is crucial for several reasons

1. System Efficiency A significant delta in pressure can indicate a blockage or leak within the refrigeration system. For instance, a high-pressure drop across a filter may suggest it requires cleaning or replacement, ensuring optimal airflow and performance.

2. Preventative Maintenance Regular monitoring of differential pressure allows for early detection of potential issues. By addressing these problems before they escalate, businesses can avoid costly repairs and unplanned downtime.

3. Energy Savings An efficiently functioning refrigeration system operates at lower energy costs. Differential pressure gauges help maintain this efficiency, leading to reduced electricity bills and a smaller carbon footprint.

4. Product Quality In commercial operations like restaurants or food storage facilities, maintaining precise temperature and humidity levels is vital. Differential pressure monitoring helps ensure that products are stored under optimal conditions, thus maintaining their quality and safety.

Types of Differential Pressure Gauges

Several types of differential pressure gauges are available, each designed to suit specific applications within the refrigeration sector. Key types include

1. Mechanical Differential Pressure Gauges These analog devices use a diaphragm or a capsule that flexes under varying pressures. They are simple, reliable, and do not require any external power source, making them suitable for many basic applications.

refrigeration differential pressure gauge products

2. Electronic Differential Pressure Gauges These digital devices provide more advanced features, including data logging, remote monitoring capabilities, and enhanced accuracy. They are used in complex systems where precision is paramount.

3. Manometer Type Gauges These gauges measure pressure differences using fluid columns, thus displaying the pressure difference in a visual format. They are often used in systems where a straightforward pressure reading is sufficient.

4. Transducer-based Gauges These use electronic sensors to detect pressure differences and convert them into electrical signals. They are often integrated into automated control systems for real-time monitoring and adjustments.

Choosing the Right Differential Pressure Gauge

When selecting a differential pressure gauge for refrigeration systems, several factors should be considered

1. Pressure Range Understanding the pressure range within your refrigeration system is crucial. Gauges should be selected with appropriate ranges to ensure accuracy and reliability.

2. Material Compatibility Select gauges made from materials compatible with the refrigerants used in your system to avoid corrosion and ensure longevity.

3. Installation Requirements Consider the installation space and the complexity of the gauge. Some models might require more intricate mounting processes, while others may be more straightforward.

4. Calibration and Maintenance Regular calibration ensures the accuracy of readings. Choose products that are easy to calibrate or come with factory settings for convenience.

Conclusion

Refrigeration differential pressure gauges are essential tools in maintaining efficient and reliable refrigeration systems. By monitoring pressure differences, businesses can improve efficiency, enhance product quality, and save on energy costs. With various types of gauges available, it's essential to choose the right one based on application-specific requirements. Proper understanding and utilization of differential pressure gauges can lead to a significant improvement in refrigeration system performance and longevity.

For anyone involved in the refrigeration industry or related fields, investing in high-quality differential pressure gauges is a step towards enhanced operational efficiency and cost savings. Whether through mechanical models or advanced digital gauges, these instruments are an indispensable part of effective refrigeration management.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025