Dec . 13, 2024 06:28 Back to list

refrigeration differential pressure gauge manufacturer

Understanding Refrigeration Differential Pressure Gauges Importance and Applications

In the realm of refrigeration systems, the efficiency and performance of these systems are crucial for maintaining optimal temperatures and ensuring the longevity of perishables. One of the critical tools in this sector is the differential pressure gauge. This instrument plays an essential role in monitoring and managing pressures within refrigeration systems, providing valuable information that helps maintain system integrity and efficiency.

What is a Differential Pressure Gauge?

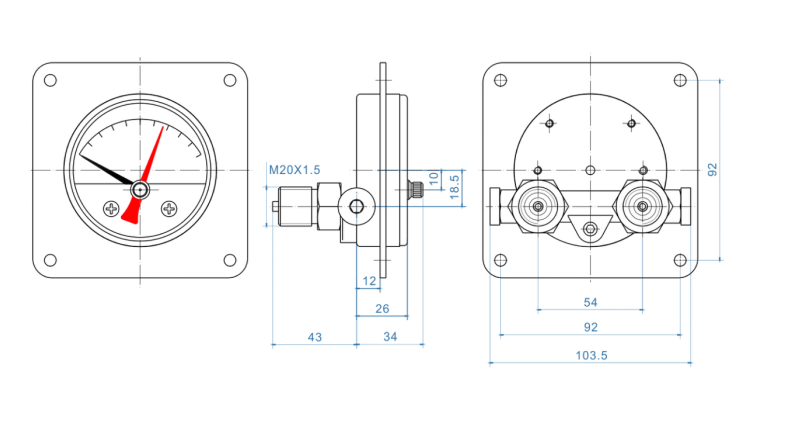

A differential pressure gauge is designed to measure the difference in pressure between two points within a system. In refrigeration, it can monitor the pressure difference across filters, evaporators, condensers, and other components. This measurement is vital for assessing the health and performance of the refrigeration system. Calculating the differential pressure helps technicians identify blockages, leaks, and performance inefficiencies, thereby ensuring that the system operates optimally.

Importance of Differential Pressure Gauges in Refrigeration

1. System Monitoring One of the primary functions of a differential pressure gauge is to offer real-time monitoring of a refrigeration system’s performance. By providing continuous feedback on pressure differentials, technicians can detect early signs of malfunctions or deviations from optimal performance.

2. Energy Efficiency Operating a refrigeration system efficiently can lead to significant energy savings. A differential pressure gauge assists in identifying when components, such as filters and heat exchangers, may need cleaning or replacement. Clogged filters or malfunctioning coils can increase energy consumption; hence, regular monitoring can facilitate timely maintenance, ultimately improving energy efficiency.

refrigeration differential pressure gauge manufacturer

3. Preventive Maintenance By routinely checking the differential pressures, maintenance teams can enact proactive measures before minor issues escalate into critical failures. This practice not only helps in extending the lifespan of equipment but also minimizes costly downtime, leading to more stable operations.

4. Safety Assurance Refrigeration systems often operate under high pressure, which can pose safety risks if not managed properly. Differential pressure gauges play a vital role in monitoring pressure differences that could indicate hazardous conditions. By identifying abnormal pressure differentials, technicians can intervene before potential failure occurs, ensuring the safety of personnel and protecting the integrity of products being stored.

Choosing the Right Manufacturer

When it comes to selecting a differential pressure gauge for refrigeration applications, choosing a reputable manufacturer is crucial. A reliable manufacturer will provide gauges that meet industry standards, ensuring accuracy and durability. Look for features such as

- Range and Accuracy Ensure the gauge can handle the expected operational pressures and provides precise readings. - Material Quality The materials used should be resistant to refrigerants and other fluids encountered in the system. - Ease of Installation and Maintenance Consider gauges that allow for easy installation and upkeep, facilitating smoother operation.

Conclusion

Differential pressure gauges are indispensable tools in the refrigeration industry, offering critical insights into system performance and health. By understanding the importance of these gauges and choosing the right manufacturers, businesses can significantly enhance their operational efficiency, prolong equipment life, and ensure safety. As technology evolves, continuing to follow advancements in pressure measurement will lead to even greater improvements in refrigeration system management, benefiting both operators and consumers. Investing in quality differential pressure gauges is not merely a choice; it is a necessity for anyone serious about maintaining high-efficiency refrigeration systems.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025