Jun . 15, 2024 22:09 Back to list

Protective diaphragm pressure gauge for renowned safety

The Importance of the Famous Diaphragm Protection Pressure Gauge in Industrial Applications

In the realm of industrial instrumentation and process control, one device that stands out for its precision and reliability is the famous Diaphragm Protection Pressure Gauge. This specialized instrument plays a crucial role in ensuring safety and efficiency across various sectors, from oil and gas to chemical processing and water treatment plants.

A pressure gauge, at its core, measures the force exerted by a fluid or gas on a surface. However, the diaphragm protection element adds an extra layer of defense, enhancing the gauge's performance in harsh environments. The diaphragm, typically made of stainless steel or other corrosion-resistant materials, acts as a barrier between the measured medium and the gauge mechanism, protecting it from contaminants, high temperatures, and aggressive fluids.

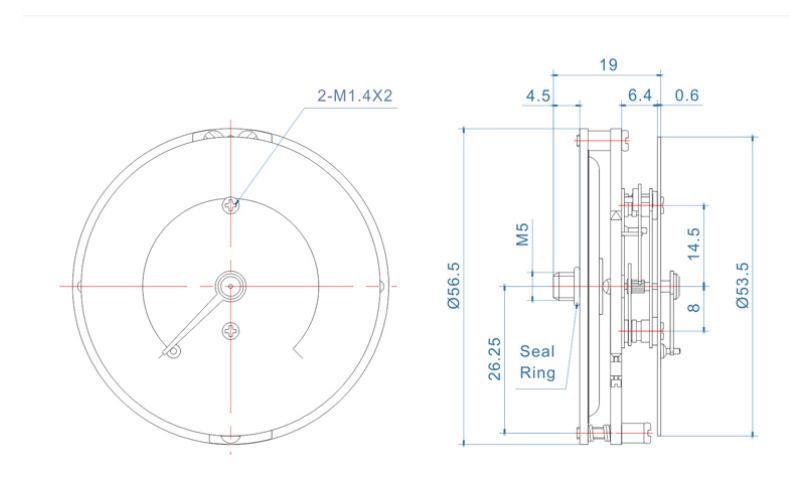

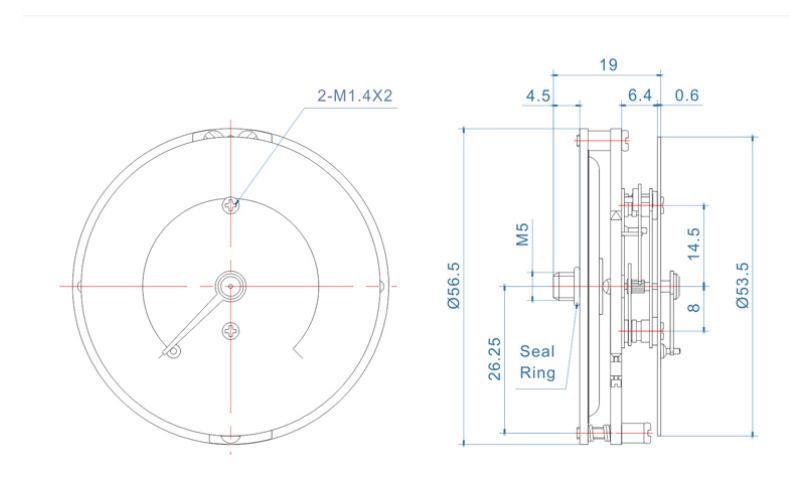

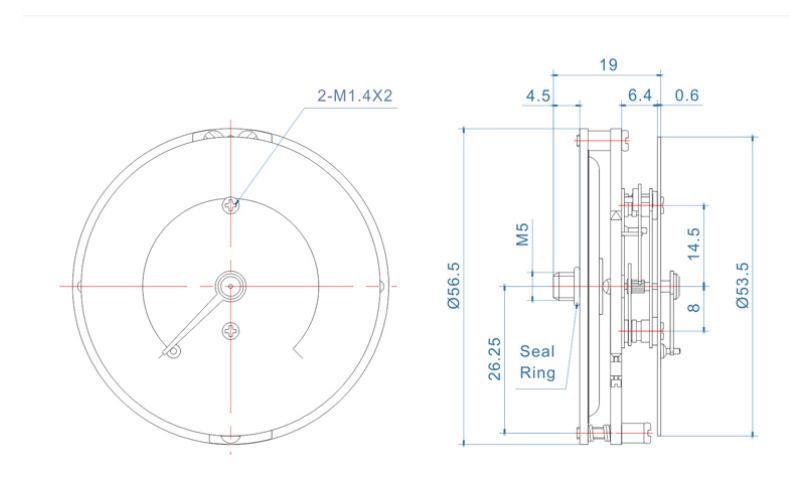

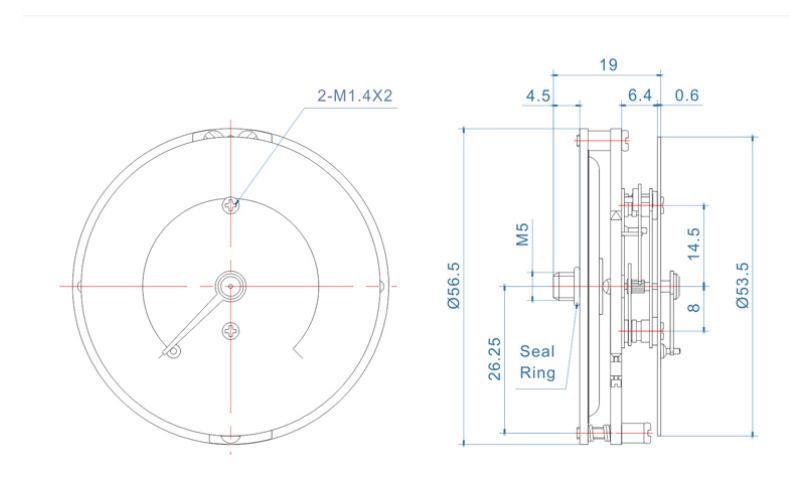

The diaphragm protection pressure gauge operates on a simple principle. The pressure exerted on the diaphragm causes it to deflect, which in turn changes the position of a mechanical indicator or transmits the signal to an electronic sensor. This deflection is proportional to the applied pressure, providing an accurate reading. The diaphragm's design allows for low-pressure measurement with high accuracy, making it ideal for applications where precise monitoring is essential.

In industries like petrochemicals, where high-temperature and corrosive substances are commonplace, the diaphragm gauge is indispensable. It safeguards the internal components from damage, extending the lifespan of the equipment and minimizing maintenance costs It safeguards the internal components from damage, extending the lifespan of the equipment and minimizing maintenance costs It safeguards the internal components from damage, extending the lifespan of the equipment and minimizing maintenance costs It safeguards the internal components from damage, extending the lifespan of the equipment and minimizing maintenance costs

It safeguards the internal components from damage, extending the lifespan of the equipment and minimizing maintenance costs It safeguards the internal components from damage, extending the lifespan of the equipment and minimizing maintenance costs famous diaphragm protection pressure gauge. Moreover, in situations where process fluids may contain solids or particles, the diaphragm prevents blockages, ensuring uninterrupted flow measurement.

Furthermore, the diaphragm protection pressure gauge is also vital in the food and pharmaceutical industries due to its ability to maintain hygiene standards. Its smooth surface and ease of cleaning meet the strict requirements, preventing contamination of the processed materials.

In addition to its protective functions, the diaphragm gauge is also known for its versatility. It can be customized with different materials, connection types, and pressure ranges to suit specific application needs. Its compact size and robust construction make it suitable for both field and panel mounting.

In conclusion, the famous diaphragm protection pressure gauge is more than just a measuring tool; it is a guardian of industrial safety and process integrity. Its innovative design and inherent resilience have solidified its position as a cornerstone in numerous industries. As technology advances, we can expect further improvements in diaphragm gauge technology, ensuring continued reliability and precision in even the most challenging pressure measurement scenarios.

famous diaphragm protection pressure gauge. Moreover, in situations where process fluids may contain solids or particles, the diaphragm prevents blockages, ensuring uninterrupted flow measurement.

Furthermore, the diaphragm protection pressure gauge is also vital in the food and pharmaceutical industries due to its ability to maintain hygiene standards. Its smooth surface and ease of cleaning meet the strict requirements, preventing contamination of the processed materials.

In addition to its protective functions, the diaphragm gauge is also known for its versatility. It can be customized with different materials, connection types, and pressure ranges to suit specific application needs. Its compact size and robust construction make it suitable for both field and panel mounting.

In conclusion, the famous diaphragm protection pressure gauge is more than just a measuring tool; it is a guardian of industrial safety and process integrity. Its innovative design and inherent resilience have solidified its position as a cornerstone in numerous industries. As technology advances, we can expect further improvements in diaphragm gauge technology, ensuring continued reliability and precision in even the most challenging pressure measurement scenarios.

It safeguards the internal components from damage, extending the lifespan of the equipment and minimizing maintenance costs It safeguards the internal components from damage, extending the lifespan of the equipment and minimizing maintenance costs

It safeguards the internal components from damage, extending the lifespan of the equipment and minimizing maintenance costs It safeguards the internal components from damage, extending the lifespan of the equipment and minimizing maintenance costs famous diaphragm protection pressure gauge. Moreover, in situations where process fluids may contain solids or particles, the diaphragm prevents blockages, ensuring uninterrupted flow measurement.

Furthermore, the diaphragm protection pressure gauge is also vital in the food and pharmaceutical industries due to its ability to maintain hygiene standards. Its smooth surface and ease of cleaning meet the strict requirements, preventing contamination of the processed materials.

In addition to its protective functions, the diaphragm gauge is also known for its versatility. It can be customized with different materials, connection types, and pressure ranges to suit specific application needs. Its compact size and robust construction make it suitable for both field and panel mounting.

In conclusion, the famous diaphragm protection pressure gauge is more than just a measuring tool; it is a guardian of industrial safety and process integrity. Its innovative design and inherent resilience have solidified its position as a cornerstone in numerous industries. As technology advances, we can expect further improvements in diaphragm gauge technology, ensuring continued reliability and precision in even the most challenging pressure measurement scenarios.

famous diaphragm protection pressure gauge. Moreover, in situations where process fluids may contain solids or particles, the diaphragm prevents blockages, ensuring uninterrupted flow measurement.

Furthermore, the diaphragm protection pressure gauge is also vital in the food and pharmaceutical industries due to its ability to maintain hygiene standards. Its smooth surface and ease of cleaning meet the strict requirements, preventing contamination of the processed materials.

In addition to its protective functions, the diaphragm gauge is also known for its versatility. It can be customized with different materials, connection types, and pressure ranges to suit specific application needs. Its compact size and robust construction make it suitable for both field and panel mounting.

In conclusion, the famous diaphragm protection pressure gauge is more than just a measuring tool; it is a guardian of industrial safety and process integrity. Its innovative design and inherent resilience have solidified its position as a cornerstone in numerous industries. As technology advances, we can expect further improvements in diaphragm gauge technology, ensuring continued reliability and precision in even the most challenging pressure measurement scenarios. Share

Latest news

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025