Dec . 28, 2024 14:45 Back to list

pressure gauge with diaphragm seal and manifold exporter

The Importance of Pressure Gauges with Diaphragm Seal and Manifold Exporters

Pressure measurement is a critical aspect of many industrial processes, ensuring the safety, efficiency, and reliability of operations. Among various pressure measurement tools, pressure gauges with diaphragm seals and manifold exporters stand out due to their ability to provide accurate measurements in challenging environments.

Understanding Pressure Gauges with Diaphragm Seals

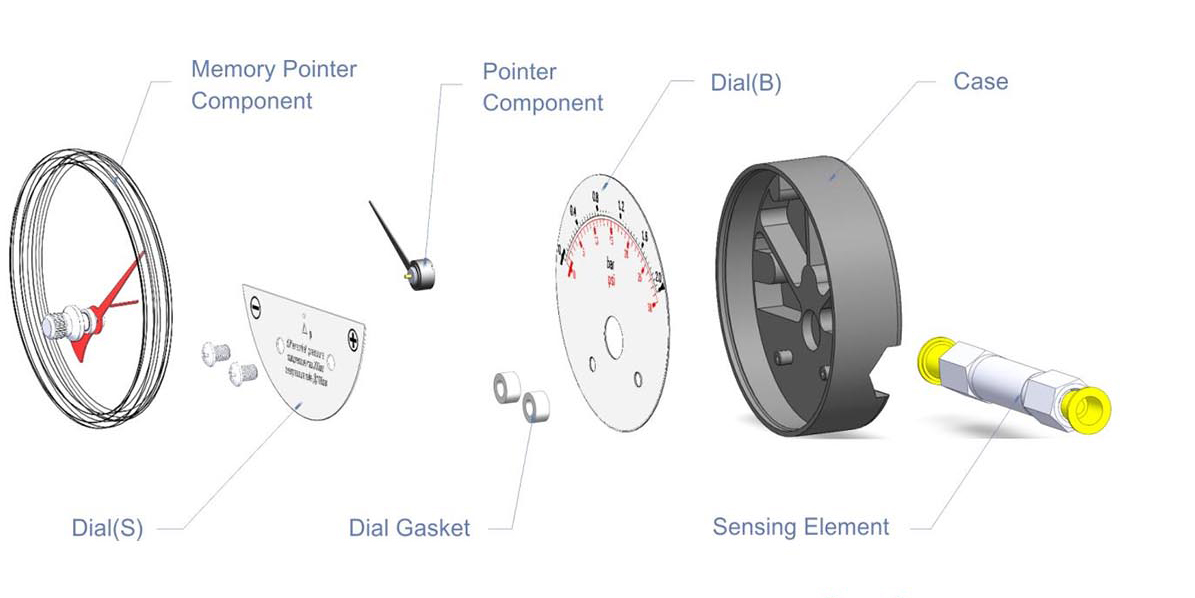

Pressure gauges are devices used to measure the pressure of gases or liquids in various systems. A diaphragm seal is a crucial component in pressure gauges, especially when dealing with corrosive, viscous, or high-temperature media. The diaphragm acts as a barrier, allowing pressure from the process fluid to exert force on the gauge mechanism while preventing direct contact between the fluid and the gauge internals. This feature enhances measurement accuracy and prolongs the gauge's lifespan.

Diaphragm-sealed gauges are particularly beneficial in industries where contaminants can compromise data integrity. For example, in chemical processing or food and beverage production, the purity of the process fluid is paramount. By using diaphragm seals, not only do engineers get precise readings but also protect the integrity of the product being processed.

The Role of Manifolds

A manifold is another essential component that works closely with pressure gauges. It is a piping assembly that allows multiple connections, thereby enabling the monitoring of different pressure points within a system from a single location. Manifolds facilitate the isolation of the gauge, which is essential for maintenance and calibration without interrupting the process.

Combining diaphragm seals with manifolds creates a robust system for managing pressure measurements. This combination allows for easy access to pressure readings while protecting sensitive components from hazardous fluids or gases. Additionally, this integration helps manage pressure levels in complex systems, enhancing operational safety.

Industrial Applications

pressure gauge with diaphragm seal and manifold exporter

Pressure gauges with diaphragm seals and manifold exporters find extensive applications across various industries. In the oil and gas sector, these gauges monitor pressure in pipelines and processing facilities. They endure harsh conditions and ensure reliable data collection, which is vital for safety and operational efficiency.

In pharmaceuticals, maintaining sterile conditions is essential. Diaphragm seals prevent cross-contamination during pressure measurements, ensuring that no harmful substances interfere with drug production. This adherence to strict health guidelines protects both the product and public health.

Water treatment plants also benefit from these devices. Monitoring the pressure of water in different stages of treatment allows for optimal operation and adherence to environmental regulations. The use of diaphragm-sealed gauges ensures that readings remain consistent and accurate, even in abrasive conditions.

Key Benefits

1. Enhanced Accuracy Diaphragm seals provide reliable pressure readings, minimizing errors that could arise from corrosive or viscous fluids. 2. Increased Longevity By isolating the pressure sensing element from the process fluid, diaphragm-sealed gauges resist wear and tear, reducing the need for frequent replacements. 3. Easy Maintenance Manifolds allow for quick isolation of instruments, simplifying maintenance and reducing downtime in operations. 4. Safety These devices ensure that hazardous gases or chemicals do not come into contact with sensitive gauge mechanisms, protecting both equipment and personnel. 5. Versatility They can be used in a wide range of applications across different industries, showcasing their adaptability to diverse operational needs.

Conclusion

Pressure gauges with diaphragm seals and manifold exporters represent a critical advancement in pressure measurement technology. Their design caters to the needs of industries that require precision and reliability, even in demanding conditions. As global industries continue to evolve, incorporating these sophisticated gauges into operations will be essential for maintaining high standards of safety, efficiency, and accuracy.

Whether in the oil and gas sector, pharmaceuticals, or water treatment, the significance of these tools cannot be overstated. By investing in high-quality diaphragm-sealed pressure gauges and manifolds, companies can ensure robust performance, reduce operational risks, and uphold their commitment to quality and safety. In an era where precision is paramount, these devices stand as a testament to engineering excellence and innovation.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025