Dec . 10, 2024 00:52 Back to list

Pricing List for Diaphragm Seal Pressure Gauges and Accessories

Understanding Pressure Gauges with Diaphragm Seals A Look at the Pricelist

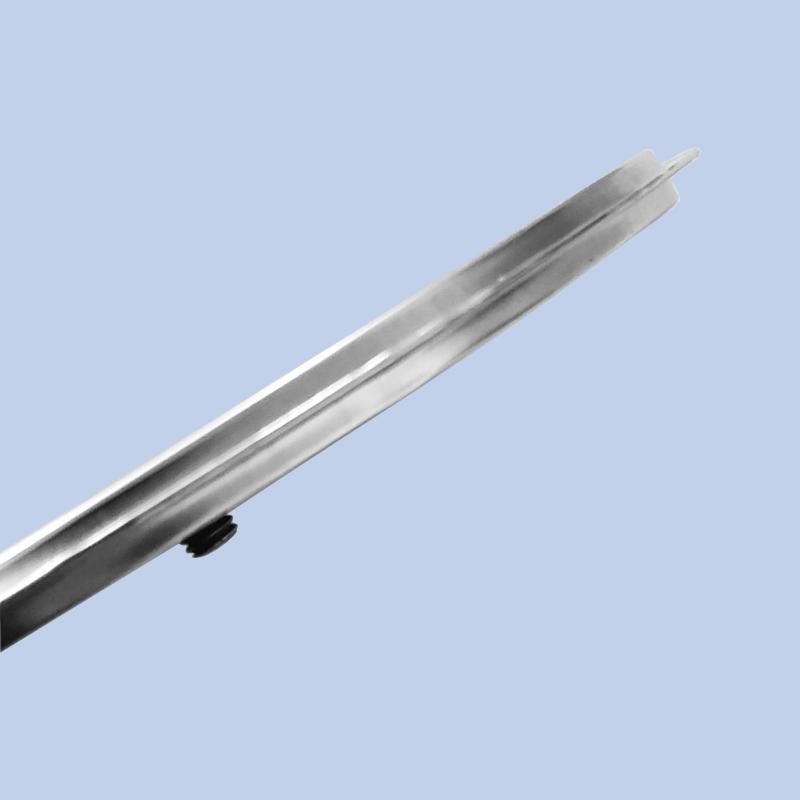

Pressure gauges are indispensable instruments commonly employed in various industrial applications to measure and display pressure levels. Among the various types of pressure gauges available, those equipped with diaphragm seals have gained significant traction due to their enhanced performance and reliability in challenging environments. This article delves into the features and advantages of pressure gauges with diaphragm seals, as well as a brief overview of their pricing.

What Are Diaphragm Seals?

Diaphragm seals are mechanical devices designed to isolate the measuring instrument from process fluids. This isolation is crucial in applications where the fluid may be corrosive, viscous, or contain particulates. A diaphragm seal consists of a flexible membrane that adjusts according to the pressure of the process fluid, transmitting this pressure to the pressure gauge without direct contact. This design not only protects the gauge but also ensures accurate readings despite fluctuating conditions.

Advantages of Pressure Gauges with Diaphragm Seals

1. Protection Against Contamination One of the primary benefits of diaphragm seals is their ability to protect sensitive gauges from contamination. By preventing direct contact with the process fluid, these seals minimize the risk of damage and ensure the longevity of the measuring instrument.

2. Accuracy and Reliability Diaphragm seals help maintain accuracy in pressure readings, especially in harsh environments. They are adept at managing variations in temperature and pressure, providing consistent performance.

3. Versatility Pressure gauges with diaphragm seals can be used in a variety of applications, including food processing, pharmaceuticals, and petrochemicals. They are suitable for both high and low-pressure systems, making them a versatile choice for many industries.

4. Reduced Maintenance Needs Since diaphragm seals protect gauges from potentially harmful substances, the maintenance requirements are significantly reduced. This leads to decreased operational costs and ensures that instruments remain operational for extended periods.

5. Customizability Many suppliers offer customizable diaphragm seals tailored to specific operational requirements, including variations in material, size, and pressure rating. This customization allows industries to select the most appropriate gauges for their unique applications.

pressure gauges with diaphragm seals pricelist

Pricing Overview

The pricing of pressure gauges with diaphragm seals can vary widely based on several factors. Here are key aspects that influence the cost

- Material Used The material of the diaphragm seal significantly impacts the price. Options include stainless steel, ceramic, and specialized alloys, each with varying resistance to corrosion and temperature changes.

- Pressure Range Gauges designed for high-pressure applications are typically more expensive than those for lower pressures. The complexity of the design and the robustness required will add to the overall cost.

- Accuracy Class Different applications may require different accuracy levels. Higher precision gauges tend to be priced at a premium due to the advanced technology involved in their manufacturing.

- Customization Tailored solutions generally come at a higher price point than standard models. Custom features may include specific thread sizes, flange types, or extended temperature ranges.

- Brand and Supplier Established brands may charge more for their reputation, warranty, and customer support services. However, opting for a lesser-known brand may result in cost savings, though it’s essential to evaluate quality and reliability.

Conclusion

Pressure gauges with diaphragm seals represent a significant advancement in pressure measurement technology. They provide a crucial layer of protection, ensuring accuracy and reliability in a wide range of applications. While the pricing of these instruments can vary based on multiple factors, the investment in quality pressure gauges typically pays off in terms of performance and reduced maintenance needs. As industries continue to evolve, pressure gauges with diaphragm seals will remain a vital component in the landscape of industrial instruments. Choosing the right gauge requires careful consideration of the application, environment, and budget to achieve the best possible outcomes.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025