Nov . 13, 2024 16:47 Back to list

pressure gauge for fire extinguisher exporter

Pressure Gauge for Fire Extinguisher Exporters Ensuring Safety and Compliance

In today's world, safety takes precedence, especially when it comes to fire prevention and control. One of the critical components in any fire extinguisher is the pressure gauge. For exporters in this specialized industry, understanding the importance and functionality of pressure gauges can significantly affect product quality and customer satisfaction.

A pressure gauge serves as an essential tool that allows users to monitor the operational status of a fire extinguisher. It indicates whether the extinguisher is in optimal working condition or if maintenance is needed. Typically marked with a colored dial, the gauge shows a range that specifies the acceptable pressure levels. If the needle falls outside this range, the extinguisher may not function effectively in an emergency, which could lead to catastrophic consequences.

For exporters, ensuring that the pressure gauges are of the highest quality is crucial. This means sourcing gauges that comply with international safety standards such as those established by the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL). These certifications not only reassure customers about the product's reliability but also protect the exporter’s reputation and liability in the market.

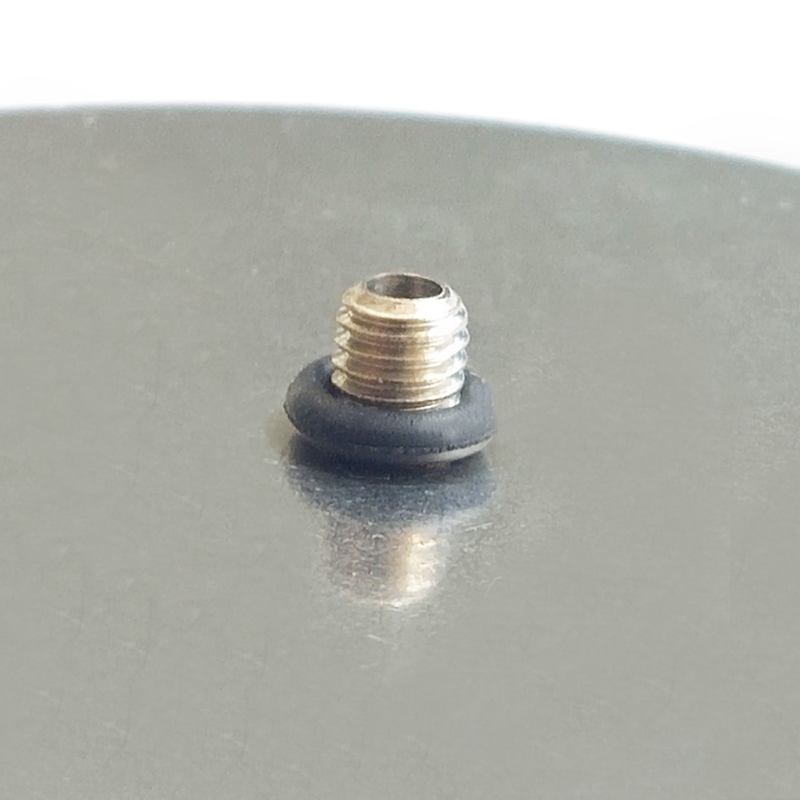

Choosing the right materials for manufacturing pressure gauges is another vital aspect. Gauges should be constructed from durable materials that can withstand extreme temperatures, physical impacts, and corrosion. Many exporters prefer brass and stainless steel for the body to enhance durability, while employing high-quality glass for clarity and visibility. Additionally, gauges should be lightweight to facilitate easy handling during emergency situations.

pressure gauge for fire extinguisher exporter

Furthermore, accuracy is paramount when it comes to pressure gauges. Exporters should collaborate with manufacturers who utilize precision manufacturing techniques and state-of-the-art calibration methods. Regular testing and quality control measures should be in place to ensure that each gauge meets stringent accuracy requirements before it leaves the production line.

Training and education play vital roles as well. Exporters should not only distribute quality products but also provide comprehensive guides that explain how to read and interpret the pressure gauges. Establishing a strong relationship with customers—be they retailers, businesses, or organizations—will enable exporters to communicate the importance of regular inspections and maintenance of fire extinguishers.

The growing global concern for fire safety has opened new markets for fire extinguisher exporters. However, distinguishing yourself in this competitive landscape requires a commitment to quality, compliance, and customer education. By emphasizing the importance of pressure gauges as part of your product offering, exporters can build a robust business model that prioritizes safety while meeting market demands.

In conclusion, pressure gauges are more than just components of fire extinguishers; they are critical indicators of safety and readiness. For exporters, understanding their importance and ensuring high quality and compliance will not only enhance customer trust but also contribute to a safer environment for all. As the world continues to take fire safety seriously, the role of exporters in this equation becomes increasingly significant, making attention to detail and commitment to excellence essential for success.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025