Nov . 29, 2024 19:37 Back to list

WIKA Diaphragm Seal Pressure Gauge Solutions for Reliable Measurement

Diaphragm Seal Pressure Gauges A Deep Dive into WIKA Products

In the world of industrial monitoring and measurement, the significance of accurate pressure readings cannot be overstated. Among the essential instruments used for this purpose are pressure gauges that provide real-time data on the pressure of various fluids and gases in a system. One innovative solution that has gained considerable recognition is the diaphragm seal pressure gauge, particularly those provided by WIKA.

WIKA is a leading manufacturer of pressure, temperature, and level measuring instruments, renowned for its commitment to quality and innovation. Their diaphragm seal pressure gauges are designed to meet the stringent requirements of various industrial applications, especially in processes involving corrosive, viscous, or high-temperature fluids that could jeopardize the integrity of standard pressure gauges.

What is a Diaphragm Seal?

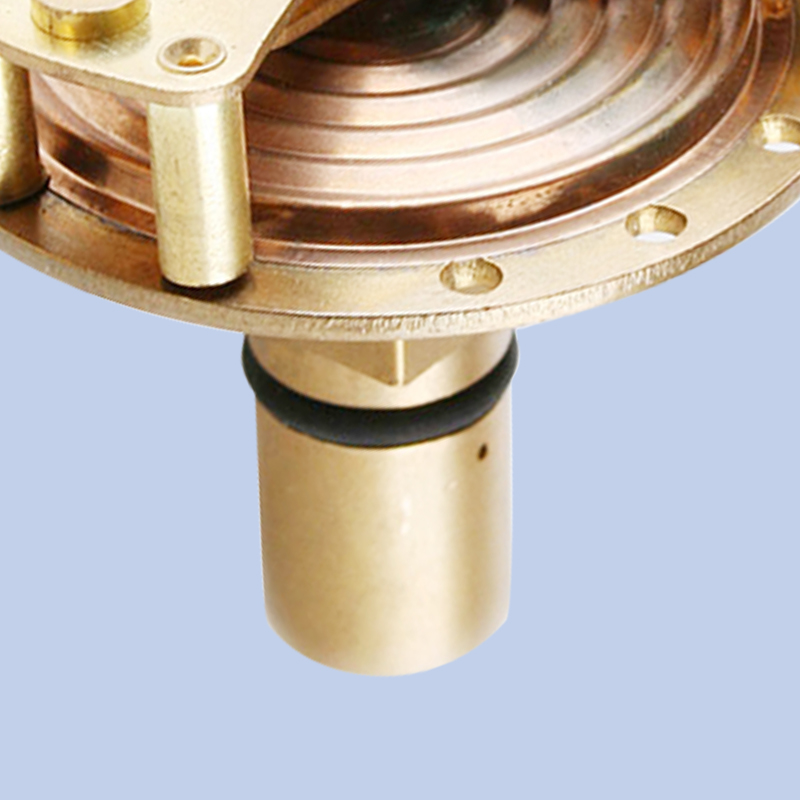

A diaphragm seal consists of a flexible membrane (the diaphragm) that separates the pressure gauge from the process media. This unique design allows the pressure gauge to measure pressure without direct contact with the potentially damaging fluids. The diaphragm deflects under pressure, transferring the force to the gauge without exposing sensitive components to harsh environments.

This feature is crucial in industries such as chemical processing, food and beverage, pharmaceuticals, and oil and gas, where the media can be corrosive or contain solids that could clog the instrument

. By isolating the gauge from direct exposure, WIKA's diaphragm seal pressure gauges enhance measurement reliability and reduce maintenance costs.Advantages of WIKA Diaphragm Seal Pressure Gauges

pressure gauge diaphragm seal wika product

1. Corrosion Resistance WIKA offers a range of materials for the diaphragm, including stainless steel, Hastelloy, and Teflon, ensuring compatibility with various media. This resistance to corrosion maximizes the lifespan of the gauge. 2. High Accuracy These gauges maintain high accuracy even under extreme pressure fluctuations. WIKA’s proprietary technology ensures that measurements remain precise and reliable, critical for maintaining safety and efficiency in industrial operations.

3. Adaptability WIKA's diaphragm seal pressure gauges are versatile, with customizable options that cater to different process conditions. Users can select the appropriate diaphragm materials, sizes, and connections to suit specific applications.

4. Ease of Maintenance By keeping the pressure sensing element isolated from the process media, these gauges minimize wear and tear, requiring less frequent maintenance. This reduces downtime and enhances operational efficiency.

5. Temperature Handling Many WIKA diaphragm seal pressure gauges are designed to handle high temperatures, making them ideal for applications like steam measurement and hot fluid processing.

Conclusion

In conclusion, WIKA's diaphragm seal pressure gauges serve as a testament to the company's dedication to providing innovative and effective solutions for industrial measurement challenges. By incorporating a diaphragm seal, they protect sensitive gauge components from harsh process conditions while ensuring accurate pressure readings. For industries that demand high reliability and performance, choosing WIKA products is an investment in quality, efficiency, and safety. As industries continue to evolve, the need for robust and adaptable measurement solutions like WIKA's diaphragm seal pressure gauges will only grow, solidifying their place in the future of industrial technology.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025