Dec . 15, 2024 16:20 Back to list

Suppliers and Products for Pressure Gauge Accessories in Various Industries

Exploring the World of Pressure Gauge Accessories Suppliers

In industrial environments where precision is paramount, the need for reliable pressure measurement is undisputed. Pressure gauges serve as essential tools in various applications, from oil and gas to pharmaceuticals and food processing. To enhance their functionality, a wide range of accessories is available, provided by numerous suppliers across the globe. This article will explore the importance of pressure gauge accessories, the types available, and key factors to consider when selecting a supplier.

Importance of Pressure Gauge Accessories

Pressure gauge accessories are crucial for ensuring accurate readings and extending the lifespan of the equipment. Accessories can include protective covers, calibration tools, isolators, and tubing, each playing a pivotal role in optimizing gauge performance. For instance, protective covers shield gauges from environmental factors, while calibration tools are essential for maintaining the accuracy of the pressure readings.

Moreover, in industries where pressure levels can fluctuate dramatically, isolators and pressure-relieving devices help protect both the gauges and the systems they monitor. This not only improves safety but also enhances the reliability of critical processes.

Types of Pressure Gauge Accessories

1. Protective Covers These accessories prevent dust, moisture, and chemicals from damaging sensitive gauges. They come in various materials, such as rubber, plastic, or metal, depending on the harshness of the operating environment.

2. Calibration Equipment Regular calibration is necessary to ensure accuracy. Calibration pots and test gauges are common accessories used to verify the readings of pressure gauges and to ensure they meet industry standards.

3. Isolators These devices are installed between the pressure source and the gauge, protecting the gauge from high pressure or corrosive materials. They help maintain the integrity of the gauge while providing accurate readings.

4. Tubing and Fittings Tubing is essential for connecting pressure gauges to the process lines. Various materials, including stainless steel and flexible plastics, are used depending on the application. Additionally, appropriate fittings ensure airtight connections to prevent leaks.

5. Switches and Transmitters For more advanced applications, pressure switches and transmitters can be integrated into systems. These devices help automate processes by providing real-time pressure monitoring and alarms.

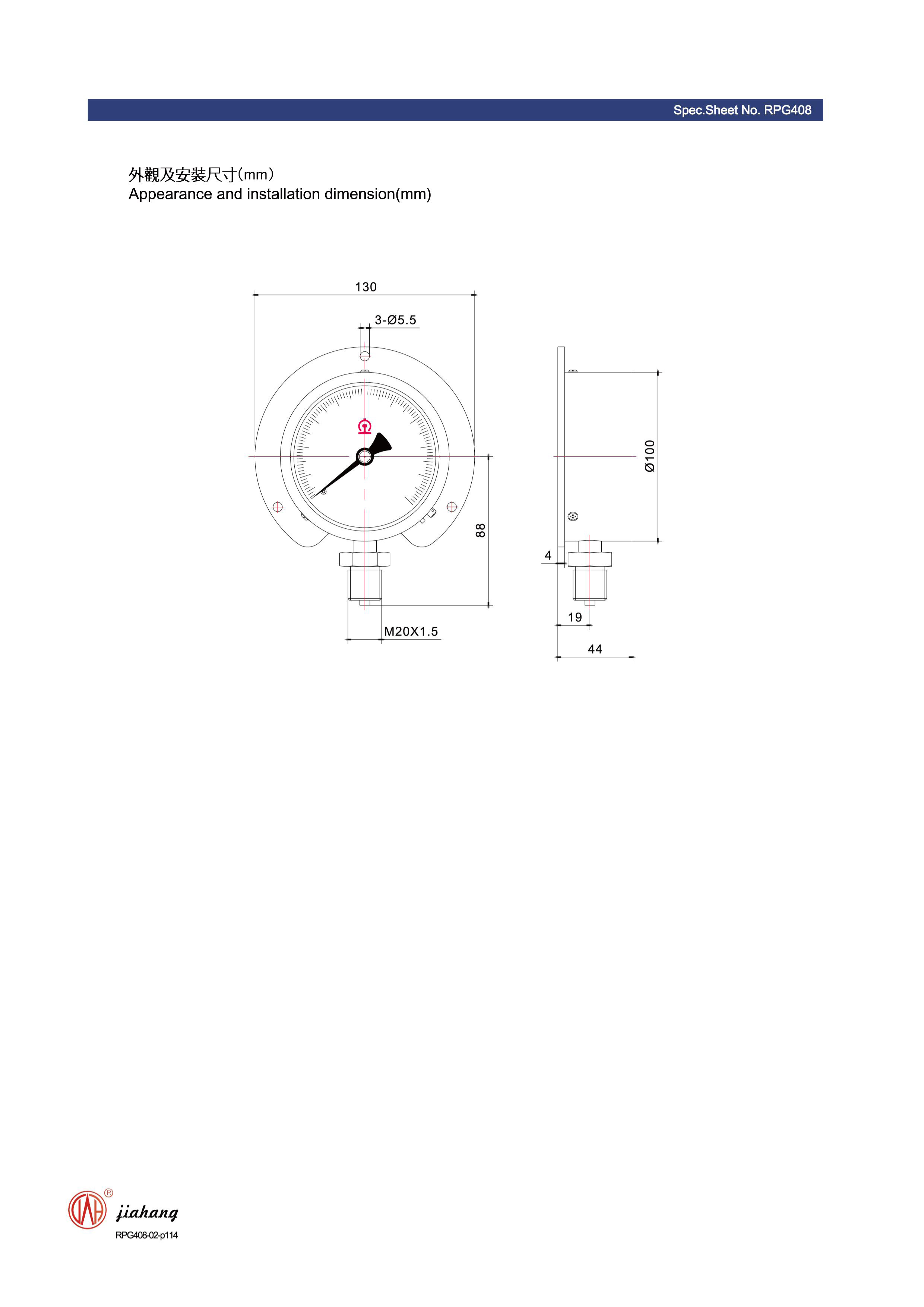

pressure gauge accessories suppliers products

Selecting a Supplier

When looking for pressure gauge accessory suppliers, several factors should be considered to ensure that you choose a reliable partner.

1. Reputation and Experience Research suppliers to assess their reputation in the industry. Manufacturers with extensive experience are often more reliable and provide high-quality products.

2. Product Variety A wide range of accessories allows for flexibility in meeting specific needs. Suppliers that offer diverse products are likely to better cater to your application requirements.

3. Quality Standards Ensure the suppliers adhere to international quality standards, such as ISO certifications. This ensures that the products are manufactured under stringent quality controls.

4. Customer Service Excellent customer support can significantly impact your purchasing experience. Evaluate the supplier’s responsiveness, technical support, and their willingness to address any concerns.

5. Pricing While price should not be the sole determining factor, it’s essential to compare prices across different suppliers to ensure that you are getting a fair deal without compromising on quality.

6. Technical Expertise Suppliers with strong technical knowledge can help in selecting the right accessories for specific applications. Their expertise can guide you in making informed choices.

Conclusion

In conclusion, pressure gauge accessories are indispensable in ensuring the accuracy and reliability of pressure measurements in various industries. As the demand for precise pressure control increases, the role of suppliers in providing high-quality accessories becomes even more crucial. When choosing a supplier, consider factors such as reputation, product variety, quality standards, customer service, and technical expertise. By making informed decisions, businesses can enhance efficiency, safety, and performance in their operations, ultimately leading to greater success in their respective fields. Investing in the right pressure gauge accessories and a reliable supplier is not just an option; it is a necessity in today’s fast-paced industrial landscape.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025