Dec . 03, 2024 23:58 Back to list

High-Performance Pressure Diaphragm Solutions for Enhanced Industrial Applications

The Importance of Pressure Diaphragm Products in Modern Engineering

In the realm of engineering and instrumentation, precision and reliability are paramount. One crucial component that has garnered significant attention in various industrial applications is the pressure diaphragm. These products play a vital role in measuring pressure accurately and safeguarding systems from potential damage due to pressure fluctuations. This article delves into the importance of pressure diaphragm products, their working principles, applications, and the factors influencing their selection.

Understanding Pressure Diaphragms

A pressure diaphragm is a flexible membrane that separates two different pressure zones. It is typically made of materials that can withstand the operational conditions, such as stainless steel, plastic, or elastomers. When pressure is applied to one side of the diaphragm, it deforms, causing a displacement that can be measured. This displacement is then converted into an electrical signal or a mechanical reading, depending on the application. Pressure diaphragms are essential components in pressure transducers and gauges, enabling accurate pressure readings in various environments.

Working Principle

The functioning of a pressure diaphragm relies on the principle of deflection. When pressure is applied, the diaphragm bends or shifts in response, causing changes in capacitance, inductance, or resistance based on the type of sensor employed. This mechanical deformation is translated into a measurable output, providing real-time data critical for monitoring and controlling processes. Modern pressure diaphragm designs often incorporate advanced materials and technologies, enhancing their sensitivity and durability, thus elevating measurement accuracy.

Applications of Pressure Diaphragm Products

Pressure diaphragm products are widely utilized across numerous industries, including

1. Oil and Gas In oil drilling and refining, accurate pressure measurements are crucial for operational efficiency and safety. Diaphragm pressure transmitters monitor pipeline pressure and prevent leaks or failures.

2. Chemical Processing The chemical industry often deals with corrosive substances and high pressure. Diaphragm seals protect instruments, ensuring that pressure readings are accurate while preventing contamination.

3. Water and Wastewater Treatment Monitoring pressure in treatment plants is essential for maintaining water quality and system integrity. Diaphragm-based pressure sensors help regulate flow and detect blockages.

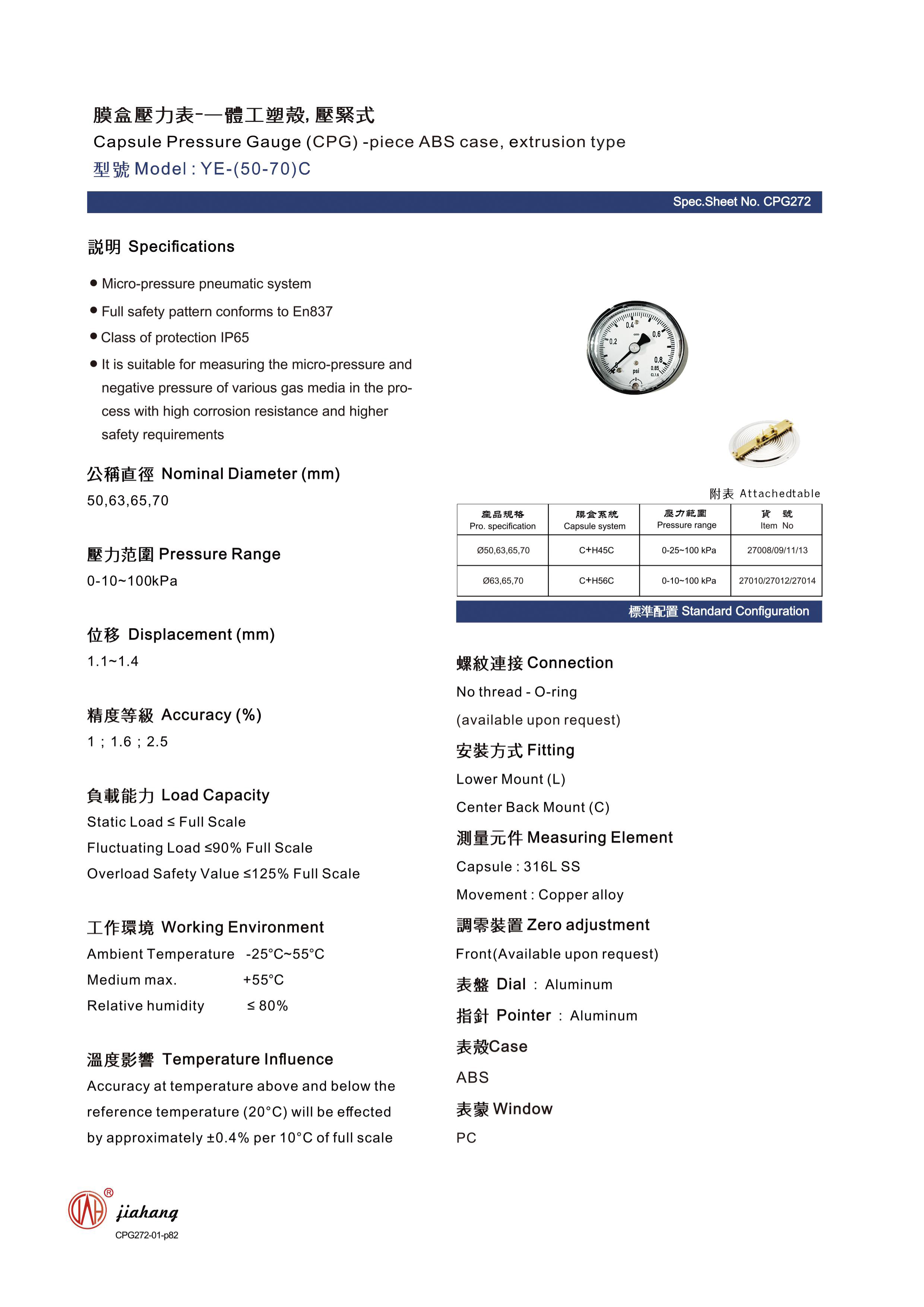

pressure diaphragm product

4. Food and Beverage In food processing, maintaining pressure is vital for ensuring product quality and safety. Stainless steel diaphragms are commonly used to meet hygiene standards while providing accurate measurements.

5. Pharmaceuticals Precise pressure control in pharmaceutical manufacturing is critical for product quality and compliance. Diaphragm pressure transducers enable accurate monitoring in sterile environments.

Factors Influencing Selection

When choosing a pressure diaphragm product, several factors must be taken into account

1. Material Compatibility The material of the diaphragm must be compatible with the fluid or gas being measured. Corrosive substances require materials like Teflon or specialized alloys to ensure durability.

2. Pressure Range Understanding the operational pressure range is crucial. Selection of a diaphragm capable of withstanding the maximum expected pressure while providing accurate measurements within the desired operational range is necessary.

3. Temperature Resistance The operating temperature can significantly affect diaphragm performance. It's essential to select a product that can withstand the temperature fluctuations present in the application.

4. Installation Requirements Some applications may demand specific mounting or integration solutions. It’s important to consider the available space and compatibility with existing systems.

5. Calibration and Maintenance Regular calibration and maintenance help ensure that pressure measurements remain accurate over time. Choosing diaphragm products designed for easy maintenance can save time and resources.

Conclusion

Pressure diaphragm products are a cornerstone of modern engineering, providing the accuracy and reliability needed in critical applications across various industries. From maintaining safety in oil and gas operations to ensuring quality in pharmaceuticals, these components enable engineers to monitor and control processes effectively. As technology advances, the development of more sophisticated diaphragm products promises to further enhance measurement capabilities, ensuring that industries can meet the challenges of a rapidly evolving landscape. With careful consideration of materials, pressure ranges, and environmental conditions, engineers can leverage the full potential of pressure diaphragm technology to achieve optimal results in their applications.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025