Nov . 16, 2024 05:33 Back to list

pressure diaphragm factory

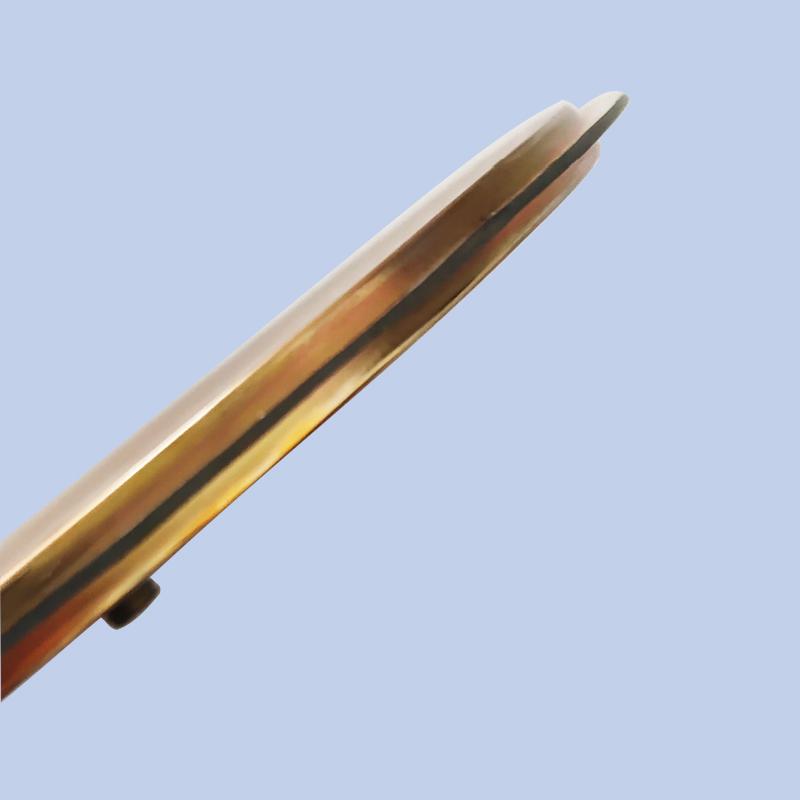

The Role of Pressure Diaphragms in Industrial Applications

In today's rapidly evolving industrial landscape, the demand for reliable and efficient components is greater than ever. One such component, the pressure diaphragm, has become essential in various applications, including measuring, controlling, and containing pressure within systems. As a bridge between technology and functionality, pressure diaphragms are crucial in ensuring operational safety and efficiency in industries ranging from oil and gas to food processing.

Understanding Pressure Diaphragms

A pressure diaphragm is a flexible membrane that responds to pressure changes in its environment. When pressure is applied, the diaphragm flexes, creating a displacement that can be converted into a measurable output. This technology is instrumental in pressure transmitters, gauges, and control systems, where precision is paramount.

The materials used in the manufacturing of pressure diaphragms are vital to their performance. Common materials include stainless steel, elastomers, and ceramics. Each material offers different advantages, such as chemical resistance, temperature withstand, and durability, making it essential for manufacturers to select the appropriate material for specific applications.

Manufacturing Process

The production of pressure diaphragms involves several critical steps that ensure their reliability and performance. It begins with the selection of high-quality raw materials, followed by processes such as cutting, shaping, and welding. For metal diaphragms, precise machining and finishing are necessary to achieve the required tolerances and surface finish.

Quality control is an integral part of the manufacturing process. Each diaphragm undergoes rigorous testing to ensure it meets industry standards and specifications. These tests typically involve subjecting the diaphragm to varying pressure levels, temperature extremes, and fatigue conditions. By ensuring that each product can withstand the demands of its intended application, factories can maintain high standards of reliability.

pressure diaphragm factory

Applications in Various Industries

Pressure diaphragms find application in a wide array of industries. In the oil and gas sector, they are used to monitor pressure in pipelines and tanks, helping to prevent leaks and ensure safe operation. In chemical processing, they are utilized in valves and pumps to regulate the flow of substances under varying pressures. The medical field relies on pressure diaphragms in devices such as blood pressure monitors and respirators, where accuracy and responsiveness are critical.

Moreover, in the food and beverage industry, pressure diaphragms play a key role in ensuring product quality and safety. They are used in equipment designed for pasteurization, sterilization, and packaging, where maintaining the correct pressure is vital for preventing contamination and ensuring product integrity.

Future Prospects

As industries continue to advance, the demand for innovative and efficient pressure measurement solutions will only increase. Manufacturers of pressure diaphragms are responding by investing in research and development to improve product capabilities. This innovation includes the integration of smart technology, such as sensors that provide real-time data monitoring and analytics.

Furthermore, as industries move toward sustainability and environmentally friendly practices, the development of pressure diaphragms made from sustainable materials is gaining traction. This shift not only meets regulatory demands but also addresses the growing consumer preference for green products.

Conclusion

In conclusion, pressure diaphragms are indispensable components in modern industrial applications. Their ability to accurately measure and regulate pressure plays a crucial role in maintaining operational safety and efficiency across various sectors. With ongoing advancements in materials science and technology, the future of pressure diaphragm manufacturing appears promising. As industries strive for greater efficiency and sustainability, the pressure diaphragm will remain at the forefront, ensuring that the systems we rely on operate smoothly and safely. Thus, investing in high-quality pressure diaphragms from a reputable factory is a decision that pays dividends in reliability and performance.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025