Sep . 08, 2024 07:18 Back to list

High-Quality Pressure Gauges with Diaphragm Seals Supplier

Pressure Gauges with Diaphragm Seals Understanding Their Importance and Benefits

In various industrial applications, the need for precise pressure measurement is paramount. Pressure gauges equipped with diaphragm seals are essential components in these scenarios, offering significant advantages over traditional gauges. A diaphragm seal not only protects the pressure measuring device but also enhances performance and reliability in demanding environments.

What are Diaphragm Seal Pressure Gauges?

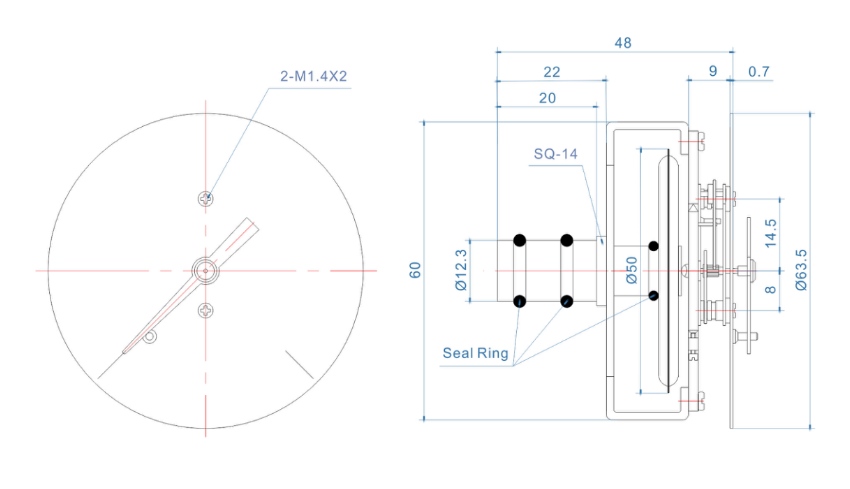

A diaphragm seal is a mechanical device designed to separate the pressure gauge from the process fluid. It consists of a flexible membrane or diaphragm that elastically deforms under pressure, transferring this pressure to the gauge while preventing direct contact with potentially corrosive, viscous, or dirty fluids. This separation ensures the longevity of the pressure gauge and accurate readings, making it a favored choice across various industries, including chemical, pharmaceutical, food and beverage, and oil and gas.

Advantages of Diaphragm Seal Pressure Gauges

1. Protection from Contaminants One of the primary benefits of using diaphragm seals is the protection they offer against process fluids that may contain contaminants, solids, or corrosive substances. The diaphragm acts as a barrier, ensuring that the gauge remains intact and operational despite harsh environmental conditions.

2. Accuracy and Reliability Diaphragm seal gauges provide highly accurate readings even in fluctuating processes. The design minimizes the effects of temperature and pressure shocks, allowing for consistent measurements.

3. Adaptability to Various Applications These gauges can be used with a wide range of media, including high-viscosity fluids, slurries, and gases. The ability to handle diverse substances makes diaphragm seal pressure gauges versatile and adaptable for numerous applications.

4. Reduced Maintenance Costs By protecting the pressure gauge from harmful media, diaphragm seals can significantly reduce maintenance frequency and costs. This results in lower downtime and increased operational efficiency.

pressure gauges with diaphragm seals supplier

5. Extended Service Life The durability of diaphragm seal pressure gauges means they often have a longer service life compared to traditional gauges. This longevity translates to further cost savings over time, making them a sound investment for industries reliant on pressure measurement.

Selecting the Right Supplier

When considering the implementation of diaphragm seal pressure gauges, selecting the right supplier is crucial. A reputable supplier will offer a variety of options tailored to the specific requirements of different applications. Key factors to consider include

- Quality and Certification Ensure that the supplier adheres to industry standards and regulations, providing gauges that are certified for use in your specific environment.

- Customization Options Depending on the application, you may require customized diaphragm seals. An experienced supplier can offer bespoke solutions to meet your unique needs.

- Technical Support and Service A reliable supplier should provide excellent customer support, including installation guidance, maintenance training, and troubleshooting assistance.

Conclusion

In conclusion, diaphragm seal pressure gauges are invaluable tools across various industries, offering enhanced protection, accuracy, and adaptability. Their ability to operate effectively in challenging conditions makes them a strategic choice for businesses focused on maintaining high standards of safety and efficiency. By partnering with a trusted supplier, industries can ensure they receive quality products that meet their operational demands, ultimately contributing to their success in a competitive marketplace.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025