Sep . 05, 2024 05:10 Back to list

pressure gauge with diaphragm seal wika service

Understanding Pressure Gauges with Diaphragm Seals A Focus on WIKA Solutions

Pressure measurement is a crucial aspect of many industrial processes, ensuring safety, efficiency, and reliability. One of the prominent solutions in this field is the pressure gauge with a diaphragm seal, a device that enhances measurement accuracy and protects the sensor from harsh environments. WIKA, a leading manufacturer in the field, provides a range of pressure gauges equipped with diaphragm seals tailored to meet various industry needs.

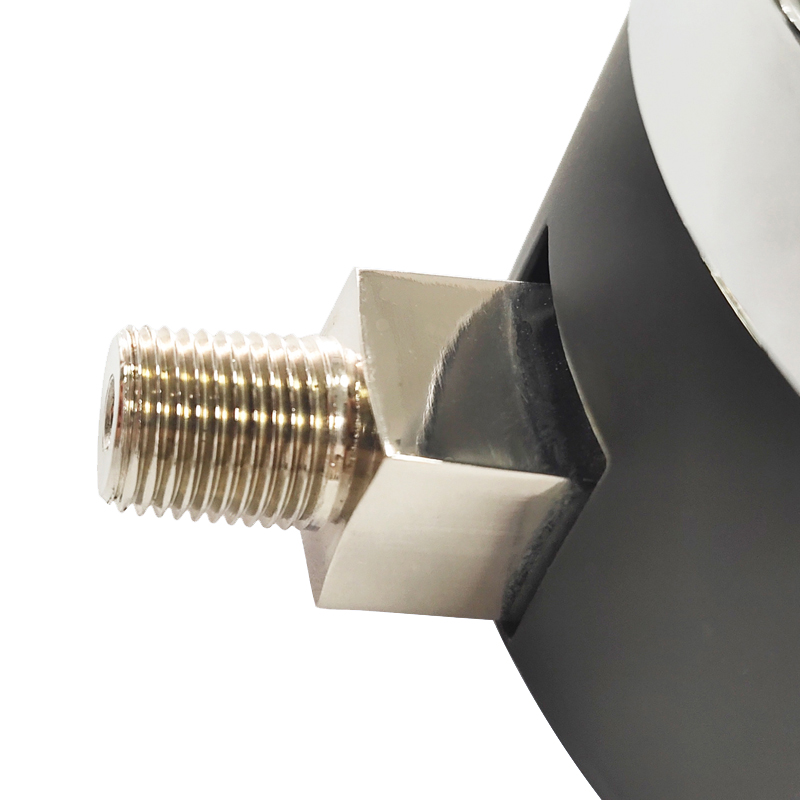

A pressure gauge with a diaphragm seal consists of a mechanical pressure sensor connected to a flexible diaphragm, which acts as a barrier between the process medium and the sensing element. This design is particularly beneficial in applications where the process fluid is corrosive, viscous, or contains solid particles. The diaphragm's ability to separate the measurement system from the harsh influences of the medium helps to prolong the life of the gauge and maintain its accuracy.

WIKA's diaphragm seal pressure gauges come in various designs and materials to accommodate different applications. For instance, they can be configured with sanitary or hygienic designs, making them suitable for the food and pharmaceutical industries, where cleanliness and sterility are paramount. The use of high-quality materials like stainless steel ensures compatibility with a wide range of aggressive media.

pressure gauge with diaphragm seal wika service

One of the standout features of WIKA's diaphragm seals is their versatility. They can be customized for different mounting configurations, sizes, and pressure ranges, allowing engineers to select the most appropriate gauge for their specific needs. Furthermore, WIKA offers models that are suitable for high-temperature and high-pressure applications, ensuring reliable performance even under extreme conditions.

Another significant advantage of using a diaphragm seal pressure gauge is its ability to reduce maintenance needs. Since the diaphragm acts as a barrier, it helps to prevent clogging and fouling of the sensing elements, which are common problems in traditional gauges. This feature not only enhances measurement reliability but also minimizes downtime and operational costs associated with maintenance.

In addition to their technical capabilities, WIKA is recognized for its commitment to quality and precision. Each pressure gauge goes through rigorous testing and quality control measures, ensuring that customers receive reliable instruments for their critical measurements.

In conclusion, WIKA's pressure gauges with diaphragm seals represent a significant advancement in pressure measurement technology. They provide the reliability, durability, and accuracy required in challenging environments, making them essential tools for industries such as oil and gas, chemicals, food processing, and many others. When it comes to ensuring process integrity and safety, investing in a quality pressure gauge like those offered by WIKA is a smart choice for any industrial operation.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025