Dec . 11, 2024 11:51 Back to list

piston type differential pressure gauge products

Understanding Piston Type Differential Pressure Gauges

Piston type differential pressure gauges play an essential role in various industrial applications, providing precise measurements of pressure differences across systems. Unlike traditional pressure gauges, these devices offer enhanced accuracy and responsiveness, making them a preferred choice for critical monitoring tasks.

What Are Piston Type Differential Pressure Gauges?

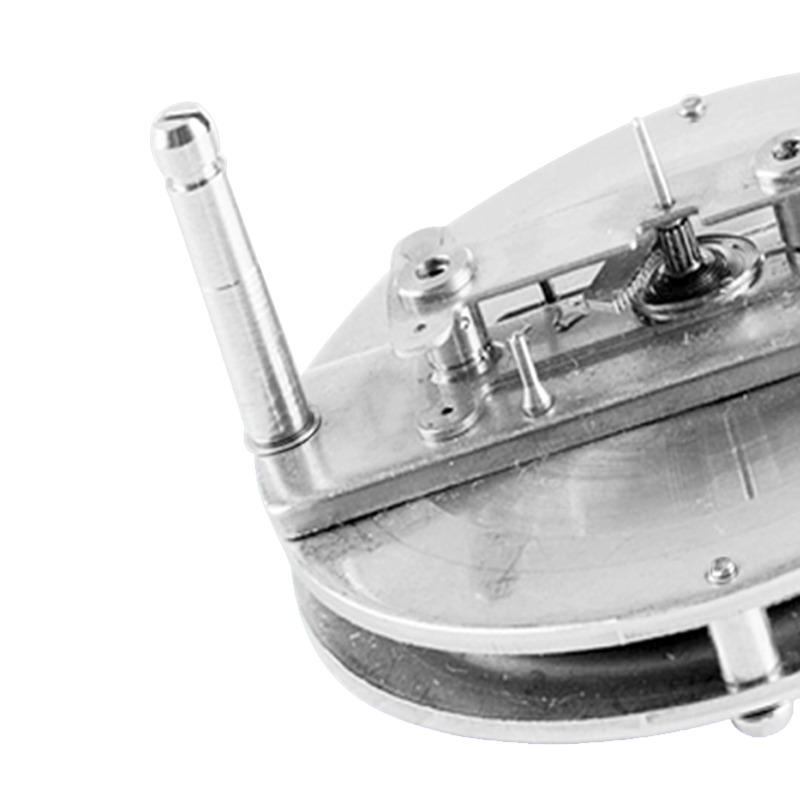

Differential pressure gauges are instruments designed to measure the difference in pressure between two points in a system. Piston type gauges use a piston mechanism to achieve this functionality. The primary working principle involves two pressures acting on either side of a piston, resulting in a net force that correlates to the differential pressure.

The design typically includes a sealed housing containing a piston that can move freely in response to pressure changes. As pressure is applied from two separate sources, the piston shifts, allowing for the calculation of the pressure differential. The displacement of the piston is then translated into a readable output, often displayed on a dial or digital screen.

Key Advantages

One of the significant benefits of piston type differential pressure gauges is their high accuracy and durability. This makes them particularly suitable for harsh environments, such as chemical processing, oil and gas exploration, and water treatment facilities. The robust design minimizes wear and tear, which is critical when dealing with potentially corrosive or abrasive substances.

Moreover, piston type gauges are highly responsive. They can quickly adapt to changes in pressure, ensuring that operators receive real-time data essential for maintaining optimal system performance. This responsiveness is crucial in processes where variations in pressure can lead to significant operational issues or safety hazards.

piston type differential pressure gauge products

Installation and Maintenance

Installing piston type differential pressure gauges requires attention to detail. Proper alignment and secure connections are vital to ensure accurate readings. Additionally, the gauges must be calibrated periodically to maintain their precision. Regular maintenance checks help identify any potential issues such as leaks or wear, which can compromise the accuracy of the measurements.

Operators should be trained in using these gauges effectively, understanding how to interpret the readings and respond to abnormal pressure levels. A well-maintained pressure gauge can significantly enhance the reliability of a system while also extending the lifespan of equipment.

Applications in Industry

Piston type differential pressure gauges find applications in many sectors. In the oil and gas industry, they are used to monitor pipeline pressures, ensuring that the transport of liquids and gases occurs safely and efficiently. In water treatment plants, they help track the pressure across filtration systems, ensuring that clean water is consistently provided.

In HVAC systems, these gauges play a crucial role in monitoring the pressure difference across filters and coils, which helps maintain air quality and energy efficiency. Moreover, the pharmaceutical industry relies on these gauges to ensure that processes remain within specified pressure limits, crucial for product safety and compliance with regulations.

Conclusion

Piston type differential pressure gauges are invaluable tools for measuring pressure differences in various industrial applications. Their accuracy, durability, and responsiveness make them ideal for demanding environments where precise measurement is critical. By investing in quality differential pressure gauges and ensuring proper installation and maintenance, industries can enhance their operational efficiency and safety. As technology advances, we can expect even greater innovations in pressure measurement instrumentation, further improving our capabilities in monitoring and controlling complex systems.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025