Oct . 22, 2024 07:49 Back to list

Piston type differential pressure gauge suppliers and manufacturers in the global market

The Importance of Piston Type Differential Pressure Gauges in Modern Industry

In the realm of industrial measurement and control, precision and reliability are paramount. Differential pressure gauges play a crucial role in various applications, ensuring that systems operate efficiently and safely. Among the different types of differential pressure gauges, piston type differential pressure gauges stand out due to their unique advantages. This article delves into the significance of piston type differential pressure gauges, their applications, and the factors to consider when exporting these instruments.

Understanding Piston Type Differential Pressure Gauges

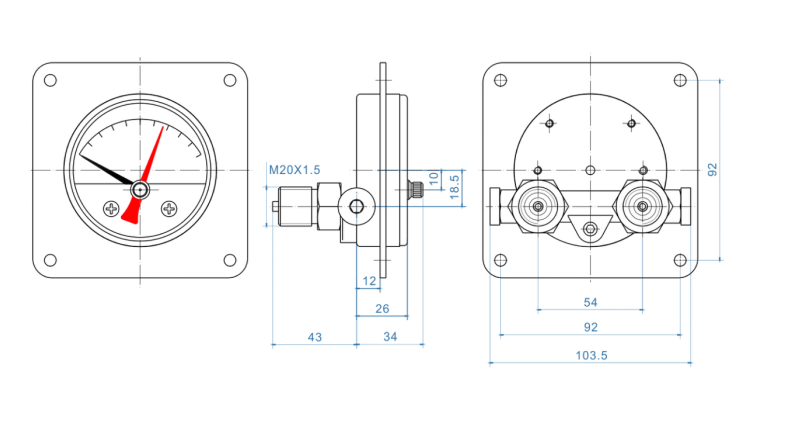

Piston type differential pressure gauges are mechanical devices that measure the difference in pressure between two points in a system. They utilize a piston that moves in response to pressure changes, translating this movement into a measurable output. This type of gauge is particularly valued for its ability to provide accurate readings in environments where fluctuations in pressure must be carefully monitored.

One significant advantage of piston type gauges is their robustness. They can withstand harsh operating conditions, including high temperatures and corrosive environments, making them suitable for industries such as oil and gas, chemical manufacturing, and pharmaceuticals. Their design allows for minimal wear and tear, ensuring long-term reliability and reduced maintenance costs.

Applications Across Industries

The versatility of piston type differential pressure gauges enables their use across a wide range of applications. In the oil and gas industry, these gauges are crucial for monitoring the pressures in pipelines and tanks. Accurate readings ensure the safe transport of petroleum products and help prevent hazardous leaks.

In the chemical sector, differential pressure gauges are essential for maintaining the integrity of process systems. They monitor pressures in reactors, filters, and separators, enabling operators to adjust processes in real time and maintain product quality. Similar applications can be found in the pharmaceutical industry, where cleanroom environments require stringent pressure control to prevent contamination.

Additionally, piston type gauges are instrumental in HVAC systems where they monitor differential pressure across filters

. This information helps in optimizing airflow and energy consumption while ensuring indoor air quality standards are met.piston type differential pressure gauge exporters

Exporting Piston Type Differential Pressure Gauges

As industries evolve globally, the demand for piston type differential pressure gauges has increased, leading to a rise in exports. For manufacturers and exporters, understanding the nuances of the market is essential for successful transactions. Here are key considerations when exporting these instruments

1. Compliance with Standards Different countries have varying regulations concerning measurement and safety standards. It is crucial to ensure that the gauges comply with international standards, such as ISO or ASTM, to facilitate smoother entry into foreign markets.

2. Quality Assurance High-quality manufacturing processes are vital when producing piston type differential pressure gauges. Ensuring that these instruments are tested for accuracy and durability can significantly enhance their credibility in the global market.

3. Customs and Tariffs Understanding the customs requirements and tariffs in the target country is essential for cost-effectiveness. Proper documentation and adherence to trade regulations can prevent delays and additional expenses.

4. Market Research Conducting thorough market research helps exporters identify potential clients and understand market demand. Tailoring marketing strategies to meet the specific needs of different regions can improve sales and customer satisfaction.

5. Technical Support and Training Offering technical support and training for end-users can differentiate an exporter from competitors. Ensuring that clients understand the operation and maintenance of differential pressure gauges fosters trust and encourages repeat business.

Conclusion

Piston type differential pressure gauges are indispensable in modern industrial applications, providing accurate and reliable pressure measurements essential for operational efficiency and safety. As the global market for these instruments continues to grow, exporters must prioritize compliance, quality, and customer support to establish a strong presence. By recognizing the significance of these gauges and addressing the needs of various industries, manufacturers and exporters can pave the way for sustainable growth and innovation in a competitive landscape. Embracing the strategic opportunities in the piston type differential pressure gauge market will ultimately lead to enhanced industrial performance and a safer working environment across multiple sectors.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025