Dec . 10, 2024 04:20 Back to list

Piston Differential Pressure Gauge Pricing and Specification Overview

Understanding Piston Differential Pressure Gauges Quotes and Insights

In the realm of industrial measurement, pressure gauges are fundamental tools that ensure equipment operates within safe and efficient parameters. Among the various types of pressure gauges, piston differential pressure gauges stand out due to their precision and reliability. This article explores the significance of these gauges, their applications, and some insightful quotes that encapsulate their value in industrial settings.

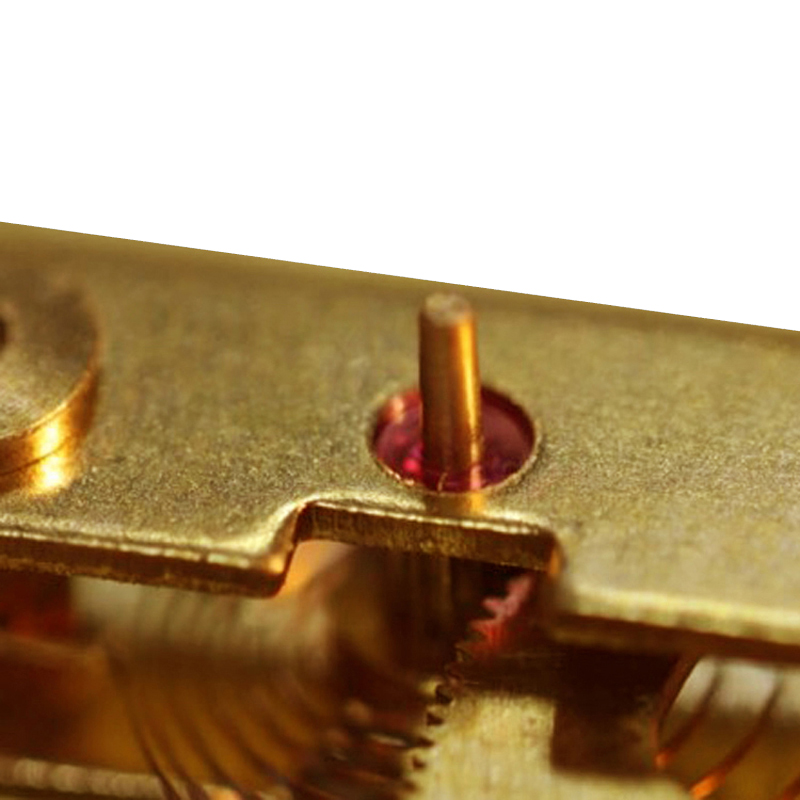

A piston differential pressure gauge measures the difference between two pressure points using a piston mechanism. This mechanism allows for the conversion of pressure difference into a readable value, making it easier for operators to monitor processes. The simplicity and accuracy of piston differential pressure gauges make them an essential choice in industries such as oil and gas, water treatment, and manufacturing.

One notable feature of these gauges is their ability to handle corrosive and viscous fluids, which can often impede the performance of traditional pressure gauges. This versatility makes them an asset in challenging environments.

As engineer and technology enthusiast Mark H. once said, “In industries where precision is paramount, the tools we trust must echo that need for exactitude.” Piston differential pressure gauges embody this sentiment by providing reliable and accurate readings that are vital for maintaining system integrity and operational efficiency.

Applications

Piston differential pressure gauges find their applications in various processes. For instance, in water treatment plants, these gauges help monitor the pressure difference between the inlet and outlet of filters. By analyzing this differential pressure, operators can schedule timely maintenance and replacements, preventing system failures and ensuring the continuous supply of clean water.

In the oil and gas sector, these gauges are crucial for monitoring pressure differences in pipelines. As energy expert John D. commented, “The lifeblood of our industries flows through pipes; understanding that flow through differential pressure is not just smart—it’s essential.” Should a significant differential pressure be detected, it might indicate a blockage or leak, allowing for immediate intervention to prevent loss and ensure safety.

piston differential pressure gauge quotes

Moreover, in HVAC systems, piston differential pressure gauges are used to measure air pressure differences across filters, ducts, and coils. Maintaining the correct airflow is vital for system efficiency, and as HVAC specialist Sarah L. noted, “Efficient air circulation starts with understanding the pressure dynamics; without the right measurements, you’re flying blind.”

Advantages of Piston Differential Pressure Gauges

One of the main advantages of piston differential pressure gauges is their mechanical simplicity. Without the need for electronic components, these gauges tend to have a longer lifespan and require less maintenance compared to electronic alternatives. Simplicity breeds reliability, said mechanical engineer David R., emphasizing the practical benefits of choosing mechanical measurement tools.

Moreover, their design allows for clear visual displays, making it easy for operators to interpret the readings quickly. This aspect is particularly advantageous in emergency situations where time is of the essence. The transparency and straightforward functionality of these gauges are often summarized by technician Amy T. who remarked, When the pressure is on, the last thing you want is complexity.

Conclusion

Piston differential pressure gauges are indispensable instruments in many industrial applications, allowing for precise monitoring of pressure differences that can dictate the safety and efficiency of operations. Their mechanical reliability, versatility, and straightforward nature make them an ideal choice for various sectors, from water treatment to oil and gas.

As industries continue to evolve and demand greater accuracy, the value of piston differential pressure gauges will only increase. In a world where knowing the precise dynamics of fluid flow can make the difference between success and failure, these gauges remind us that, as physicist Lisa G. once stated, At the intersection of measurement and understanding lies the path to progress. In essence, investing in reliable measurement tools is not merely a technical choice but a strategic decision for the future of industrial operations.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025