Dec . 31, 2024 11:09 Back to list

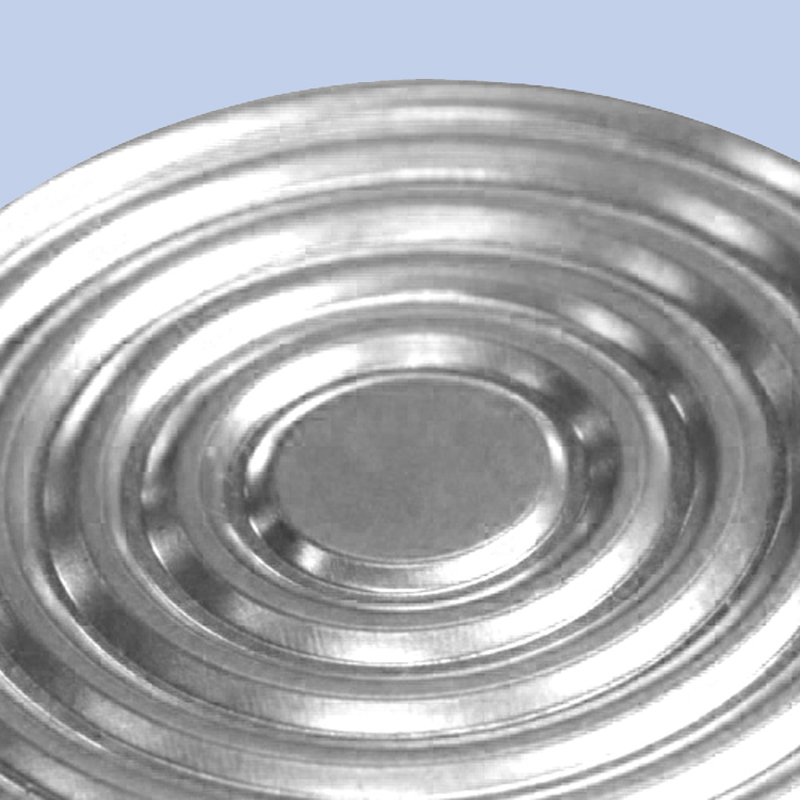

piston-style differential pressure gauges products

Understanding Piston-Style Differential Pressure Gauges

In various industrial applications, accurate measurement of pressure differences is crucial for ensuring safety, efficiency, and optimal performance. Piston-style differential pressure gauges are instrumental in achieving this task. They offer reliable measurements across various environments, making them an essential component in many sectors, including oil and gas, water treatment, pharmaceuticals, and HVAC systems.

What are Piston-Style Differential Pressure Gauges?

Piston-style differential pressure gauges operate based on the principle of sensing variances in pressure between two points. The device utilizes a piston mechanism that moves in response to pressure changes. These gauges measure the differential pressure, which is the difference between the pressure in one environment (like a tank or pipe) and the pressure in another (such as atmospheric pressure).

The key components of these gauges include the measuring chamber, the piston, and a mechanical linkage or indicator that translates the piston movement into a readable measurement. The design ensures that the gauge can withstand dynamic pressure changes, making it a robust choice in various settings.

Advantages of Piston-Style Differential Pressure Gauges

1. High Accuracy One of the main advantages of piston-style gauges is their ability to provide precise measurements. The piston design minimizes errors caused by external factors, ensuring that readings are reliable.

2. Durability These gauges are often constructed from robust materials that can handle harsh conditions, including extreme temperatures, corrosive environments, and high-pressure scenarios. This durability ensures a longer lifespan, reducing the need for frequent replacements.

3. Low Maintenance Unlike some electronic pressure measuring devices, piston-style gauges are mechanical and typically require less maintenance. They do not depend on power sources or sensitive electronics, which can fail or require calibration.

piston-style differential pressure gauges products

4. Wide Range of Applications Piston-style differential pressure gauges are versatile and can be employed in various industries. Whether monitoring the pressure in hydraulic systems, pump operations, or filtration processes, these gauges adapt to different operational needs.

5. Ease of Installation These gauges are relatively simple to install, making them user-friendly even for those with limited technical experience.

Applications in Various Industries

- Oil and Gas In the oil and gas industry, monitoring differential pressures is essential for operational efficiency. Piston-style gauges help in managing pipeline pressures, ensuring that systems operate within safe limits.

- Water Treatment In water treatment plants, these gauges monitor pressure across filters and other filtration systems to prevent overloading and ensure the clarity and safety of the water supply.

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, maintaining the right pressure differential is vital for system performance. Piston-style gauges assist in monitoring the pressure differences between various components, ensuring that air distribution is efficient and effective.

- Pharmaceuticals In the pharmaceutical industry, maintaining sterile environments is crucial. Differential pressure gauges help monitor air pressure differentials between clean rooms and surrounding areas, ensuring compliance with safety standards.

Conclusion

Piston-style differential pressure gauges are invaluable instruments in various industrial applications. Their accuracy, durability, low maintenance needs, and versatility make them a preferred choice across several sectors. As industries continue to innovate and demand more reliable measurement solutions, the role of piston-style gauges remains central to operational efficiency and safety. Companies looking to enhance their pressure monitoring capabilities should consider the benefits of implementing these advanced gauges in their systems. Integrating reliable measurement tools like piston-style differential pressure gauges helps ensure smooth operations and consistent compliance with industry regulations.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025