Oct . 12, 2024 23:01 Back to list

parts of diaphragm pressure gauge jah

Understanding the Parts of a Diaphragm Pressure Gauge

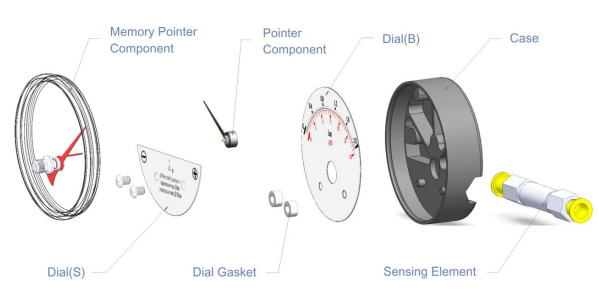

A diaphragm pressure gauge is an essential instrument used in various industries to measure pressure in liquids and gases. This device relies on a flexible diaphragm that responds to pressure changes, providing accurate readings crucial for monitoring and controlling processes. Understanding the key components of a diaphragm pressure gauge is vital for proper maintenance and effective application.

1. Diaphragm

At the heart of the diaphragm pressure gauge is the diaphragm itself, which is typically made from materials such as stainless steel, rubber, or other elastomers. The diaphragm separates the pressure medium from the internal components of the gauge. When pressure is applied, the diaphragm flexes, either deforming or bending, which translates the pressure change into a mechanical movement. This component is critical for ensuring the gauge's accuracy and durability under various operating conditions.

The pressure sensing element is connected to the diaphragm and converts the mechanical displacement into a readable measurement. This element is usually a spring mechanism that reacts to the movement of the diaphragm. The sensitivity of this component determines the gauge's response quality, affecting its ability to measure pressure accurately, especially in fluctuating systems.

3. Pointer and Dial

parts of diaphragm pressure gauge jah

The pointer and dial system displays the pressure reading. As the diaphragm flexes, the connected pointer moves across a calibrated dial, providing a visual representation of the pressure level. Dials are often marked in various units of measurement, such as psi, bar, or kPa, allowing for versatility in different applications. Accurate calibration is crucial to ensure that the pressure readings are precise and reliable.

4. Housing

The housing of a diaphragm pressure gauge protects the internal mechanisms from environmental factors such as moisture, dust, and mechanical impact. Made from durable materials like stainless steel or plastic, the housing also ensures the gauge's longevity and suitability for use in harsh conditions. Depending on the application, housings may be designed for high-temperature or corrosive environments.

5. Connection Port

The connection port is where the gauge interfaces with the pressure source. This port can accommodate various fittings and is designed to ensure a tight seal to prevent leaks. Proper installation of the connection port is critical as any leaks can lead to inaccurate readings and potential hazards.

Conclusion

Diaphragm pressure gauges are integral to efficient and safe operation in many sectors. By understanding the various parts—including the diaphragm, pressure sensing element, pointer and dial, housing, and connection port—users can ensure these devices function correctly and provide accurate pressure measurements. Regular maintenance and calibration of these components are essential practices to uphold the reliability and performance of diaphragm pressure gauges in any industrial setting.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025