Dec . 14, 2024 06:09 Back to list

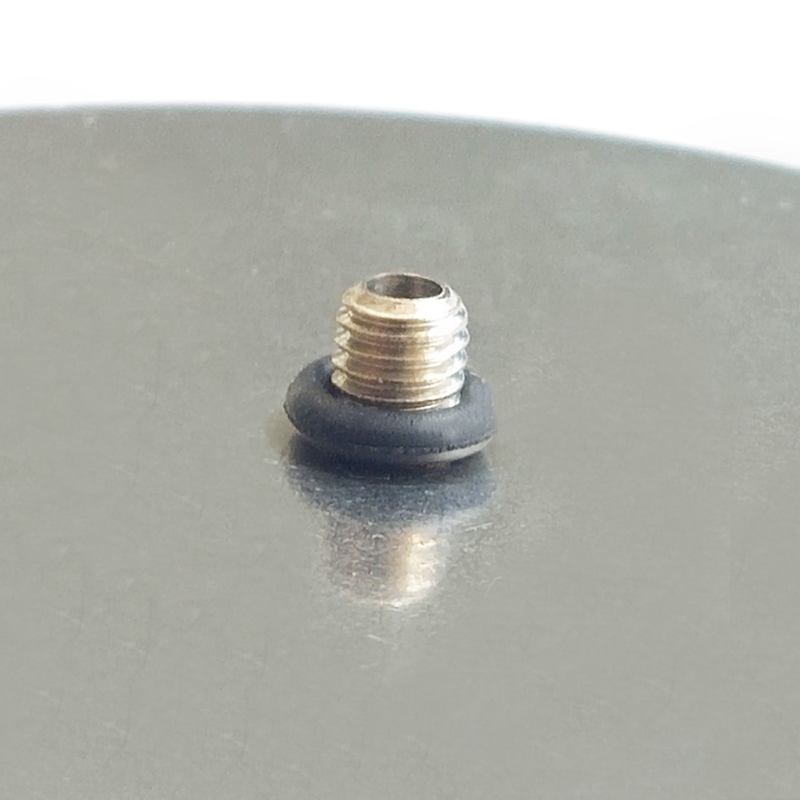

oem wika differential pressure gauge 700.04

Understanding the OEM WIKA Differential Pressure Gauge 700.04 A Comprehensive Overview

In the realm of industrial instrumentation, pressure measurement is indispensable for ensuring safety, efficiency, and performance in various applications. Among the array of pressure measurement tools available, the WIKA Differential Pressure Gauge 700.04 stands out due to its precision, reliability, and user-friendly features. This article will delve into the attributes, applications, and importance of the OEM WIKA Differential Pressure Gauge 700.04.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points within a system. It is commonly used to monitor flow rates, filter conditions, and system pressures in a variety of fields such as HVAC, oil and gas, pharmaceuticals, and water treatment. By providing real-time data regarding pressure differentials, these gauges help identify potential issues within a system before they escalate into serious problems.

Core Features of the WIKA 700.04

The OEM WIKA Differential Pressure Gauge 700.04 is specifically designed for industrial applications requiring high accuracy and durability. Some of its notable features include

1. Precision Measurement The 700.04 model is engineered to deliver precise readings with minimal error margins. This is crucial in industries where exact pressure measurements are vital for operational efficiency.

2. Robust Design Constructed with high-quality materials, the gauge is capable of withstanding harsh environmental conditions, which is essential for outdoor use or in facilities with fluctuating temperatures.

4. User-Friendly Interface The design includes an easily readable dial and scale, allowing for quick and accurate readings. Many models also feature adjustable zero-point settings, enhancing the user experience.

oem wika differential pressure gauge 700.04

5. OEM Customization As an OEM product, the WIKA 700.04 can be tailored to meet specific measurement needs, ensuring compatibility within existing systems. This flexibility makes it a preferred choice among engineers and system designers.

Applications of the WIKA 700.04

The applications of the WIKA Differential Pressure Gauge 700.04 are vast. In the HVAC industry, it is used to monitor air filter performance, indicating when filters need replacement to maintain air quality. In the oil and gas sector, the gauge helps in monitoring pressure drops across pipelines and equipment, ensuring operational safety and efficiency.

Additionally, in pharmaceuticals and food processing, maintaining precise pressure measurement is critical to compliance with stringent safety and quality standards. The WIKA 700.04 assists in controlling processes, verifying system integrity, and safeguarding product quality.

The Importance of Accurate Differential Pressure Measurement

Accurate differential pressure measurement is crucial for several reasons. Primarily, it aids in the prevention of equipment failure and potential hazards. By constantly monitoring pressure differences, operators can detect blockages or leaks early, thereby reducing downtime and maintaining consistent operational performance.

Moreover, precise measurement plays a significant role in energy efficiency. For example, in HVAC systems, a well-maintained differential pressure can optimize energy usage, translating into cost savings.

Conclusion

The OEM WIKA Differential Pressure Gauge 700.04 is a vital instrument for professionals across various industries, offering precision, durability, and versatility. Its role in ensuring safe and efficient operations cannot be overstated, making it an essential tool for monitoring and managing pressure differentials. By integrating such reliable instrumentation, industries can enhance their operational integrity and responsiveness, ultimately contributing to better performance and productivity.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025