Nov . 09, 2024 22:36 Back to list

Understanding the Functionality of Diaphragm Pressure Gauges in OEM Applications

Understanding the OEM Definition of Diaphragm Pressure Gauge

In the realm of pressure measurement, diaphragm pressure gauges hold a significant position due to their ability to provide accurate readings under varying conditions. Understanding what OEM means in this context is crucial for manufacturers, engineers, and technicians working with these instruments.

What is a Diaphragm Pressure Gauge?

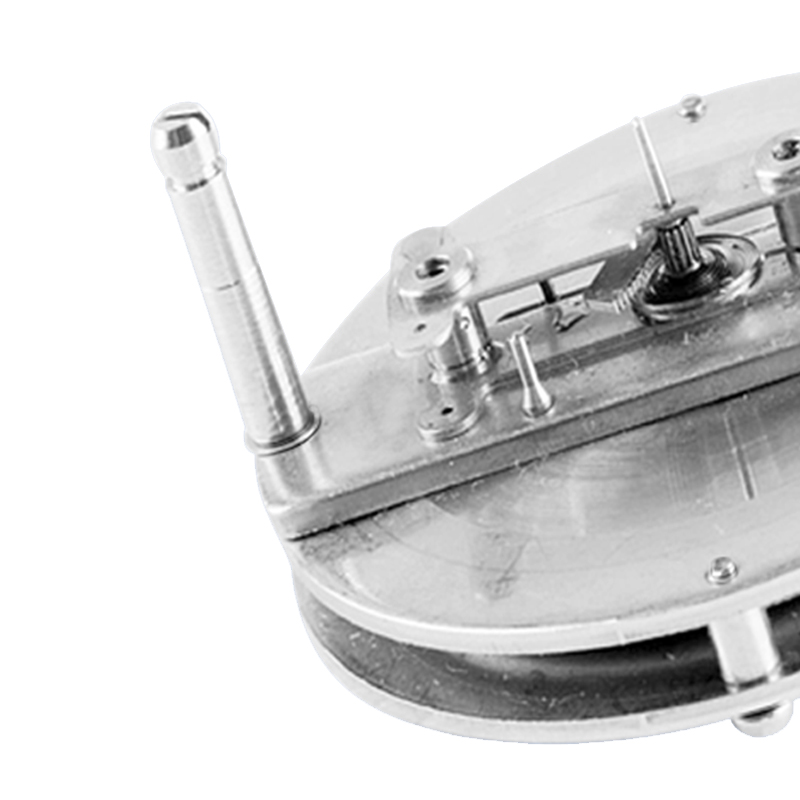

At its core, a diaphragm pressure gauge is a device that measures pressure through the deflection of a diaphragm - a flexible membrane that separates two environments one exposed to the pressure being measured and the other usually open to the atmosphere. When pressure is applied, the diaphragm flexes, and this deflection is translated into an electrical signal or gauge reading.

These gauges are particularly valued in industries dealing with gases and liquids, where high accuracy and reliability are essential. They are commonly used in environments that may be corrosive, viscous, or involve high temperatures and pressures, making them a versatile choice for numerous applications ranging from chemical processing to automotive engineering.

The Role of OEM in Diaphragm Pressure Gauges

OEM stands for Original Equipment Manufacturer. In the context of diaphragm pressure gauges, OEM refers to companies that design and produce these instruments not just for themselves, but also for other businesses that may integrate them into their own products. OEMs play a critical role in the supply chain, ensuring that high-quality components are available for end products.

Choosing an OEM for diaphragm pressure gauges carries significant implications for reliability and performance. OEMs often have stringent quality control measures in place and adhere to industry standards to provide precision-engineered components. These gauges undergo rigorous testing for durability and accuracy, ensuring that they meet the specific requirements of their applications.

oem pengertian diaphragm pressure gauge

Why OEM Diaphragm Pressure Gauges are Important

1. Quality Assurance OEM diaphragm pressure gauges are manufactured under strict quality guidelines, leading to consistent performance. The reputation of an OEM can often be tied to the effectiveness of its products; hence, customers can trust that they are getting reliable gauges that won’t fail under pressure.

2. Customization Many OEMs offer customization options to meet specific application needs. This might include varying diaphragm materials, sizes, or pressure ranges depending on the unique requirements of a given industry.

3. Technical Support and Service OEMs typically provide extensive technical support, from installation guidance to troubleshooting after the sale. This level of support is particularly important in industries where pressure gauges are critical to operational safety and efficiency.

4. Integration and Compatibility When companies manufacture their products, it is essential that all components fit seamlessly together. OEM diaphragm pressure gauges are often designed with standard fittings and interfaces, making them easier to integrate into other systems.

5. Research and Development OEMs invest in R&D to improve the design and performance of diaphragm pressure gauges constantly. The results are innovations that enhance measurement accuracy, longevity, and resistance to environmental factors.

Conclusion

In summary, diaphragm pressure gauges are vital instruments across various industries, and understanding the relationship between these devices and their OEMs is essential for anyone involved in pressure measurement. The emphasis on quality, customization, technical support, integration, and R&D makes OEM diaphragm pressure gauges the preferred choice for many professionals. As industries continue to evolve and face new challenges, the demand for reliable and accurate pressure measurement will undoubtedly rise, cementing the role of OEMs in providing solutions that meet these needs.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025