Dec . 07, 2024 10:14 Back to list

oem metal diaphragm type pressure gauges

Understanding OEM Metal Diaphragm Type Pressure Gauges

Pressure gauges are essential instruments in various industrial applications, serving as key devices for measuring the pressure of gases and liquids. Among them, the OEM metal diaphragm type pressure gauges have gained significant popularity due to their robustness, accuracy, and reliability. In this article, we will explore the features, advantages, and applications of these specialized pressure measurement tools.

What are OEM Metal Diaphragm Type Pressure Gauges?

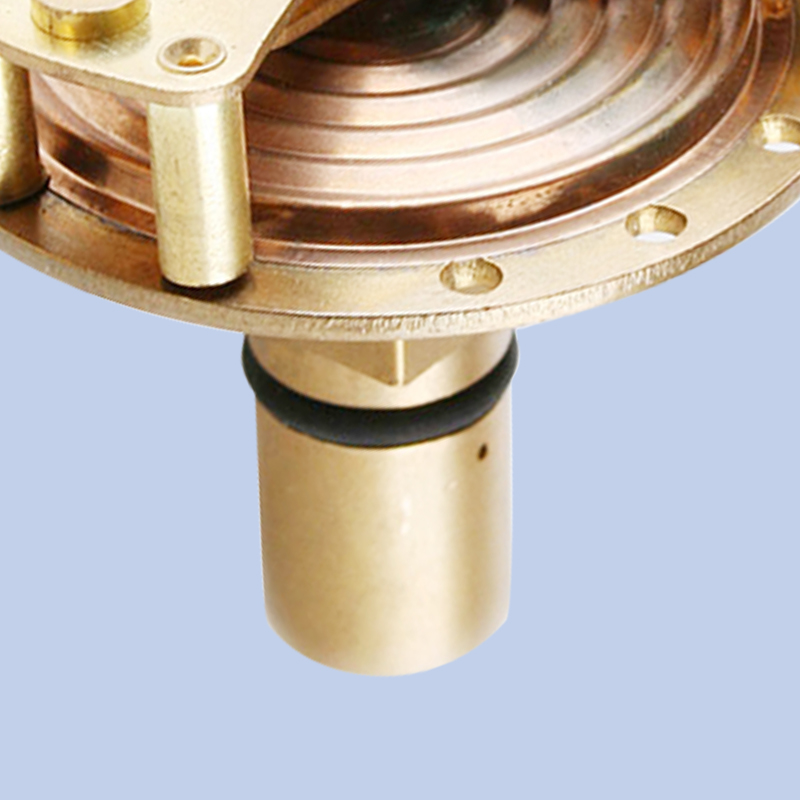

OEM, or Original Equipment Manufacturer, metal diaphragm type pressure gauges are designed specifically for integration into original equipment or for use in specialized applications. These gauges utilize a metal diaphragm as the primary pressure sensing element. The diaphragm flexes in response to pressure changes, translating mechanical motion into a readable measurement on the gauge.

The key components generally include

1. Metal Diaphragm This is often made from materials such as stainless steel, which offers durability and resistance to corrosion. 2. Bourdon Tube or Other Mechanisms While the diaphragm senses pressure, traditional gauge mechanisms such as Bourdon tubes may also be incorporated to enhance functionality. 3. Dial and Pointer The pressure reading is displayed on a dial with a calibrated scale, allowing for easy monitoring.

Advantages of Metal Diaphragm Type Pressure Gauges

1. Accuracy One of the main benefits of these gauges is their ability to provide precise measurements across a wide range of pressures. The metal diaphragm can measure small changes in pressure, which is crucial in processes that require exact readings.

2. Durability Metal diaphragms are more resistant to mechanical shock and vibrations compared to other types of diaphragms made from elastomers or plastics. This makes them suitable for use in harsh industrial environments.

3. Corrosion Resistance These gauges can be designed with materials that are highly resistant to corrosion, allowing them to function effectively in aggressive chemical environments.

4. Compact Design The construction of metal diaphragm gauges is often more compact than other types, making them easier to integrate into machinery and saving valuable space.

oem metal diaphragm type pressure gauges

Applications of OEM Metal Diaphragm Pressure Gauges

OEM metal diaphragm type pressure gauges are employed across a wide variety of industries due to their versatile nature. Some common applications include

1. Oil and Gas Industry These gauges are crucial in monitoring the pressures within pipelines and storage tanks, ensuring safe and efficient operation.

2. Chemical Processing The resistance to corrosion makes them ideal for measuring pressures in the transport and processing of chemicals.

3. Food and Beverage Industry Maintaining precise pressure in food processing applications is essential for quality control, where these gauges prove invaluable.

4. Pharmaceuticals In environments where sterility and precision are paramount, metal diaphragm gauges offer reliability for monitoring processes and equipment.

5. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges are used to monitor pressure in refrigerant lines and ensure efficient operation.

Conclusion

OEM metal diaphragm type pressure gauges represent a robust solution for precise pressure measurement in diverse applications. Their accuracy, durability, and ability to thrive in harsh conditions make them an indispensable tool in many industries. As technology continues to advance, these gauges will likely evolve further, offering enhanced features and greater integration capabilities for OEMs. Understanding and utilizing these gauges correctly can lead to improved operational efficiency and safety across various applications.

In summary, whether you are working in the chemical industry or overseeing a manufacturing plant, incorporating OEM metal diaphragm type pressure gauges into your equipment can enhance your capability to monitor and control pressure effectively.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025