Nov . 24, 2024 13:08 Back to list

Exploring OEM Magnehelic Differential Pressure Gauges for Accurate Measurements and Applications

Understanding OEM Magnehelic Differential Pressure Gauges

Differential pressure gauges are essential tools in various industrial applications, providing valuable insights into pressure variations across different points in a system. Among the many types of differential pressure gauges available, OEM Magnehelic differential pressure gauges have gained significant attention due to their accuracy, reliability, and ease of use.

What is a Magnehelic Differential Pressure Gauge?

The Magnehelic gauge operates on the principle of differential pressure measurement. It utilizes a unique design that allows it to measure pressure differences between two points accurately. The gauge consists of a flexible diaphragm that moves in response to pressure changes, translating these movements into a readable display. The name Magnehelic comes from the magnetic sensing technology employed in its design, which enhances precision and reduces wear.

One of the standout features of the Magnehelic gauge is its ability to measure low-pressure differentials, making it particularly useful in applications where precision is critical. These gauges are often employed in HVAC systems, clean rooms, laboratory environments, and various industrial processes.

Key Benefits of OEM Magnehelic Differential Pressure Gauges

1. Accuracy OEM Magnehelic gauges are known for their high degree of accuracy. They are calibrated to ensure that pressure readings are precise, allowing industries to maintain optimal operating conditions and prevent equipment failures.

2. Durability Built to withstand harsh industrial environments, these gauges are made with robust materials. Their durability reduces maintenance requirements and extends the lifespan of the equipment.

3. Ease of Installation and Use The installation process for OEM Magnehelic gauges is straightforward. They come equipped with clear instructions, allowing technicians to set them up quickly. Additionally, the user-friendly interface makes it easy for operators to read and interpret pressure measurements.

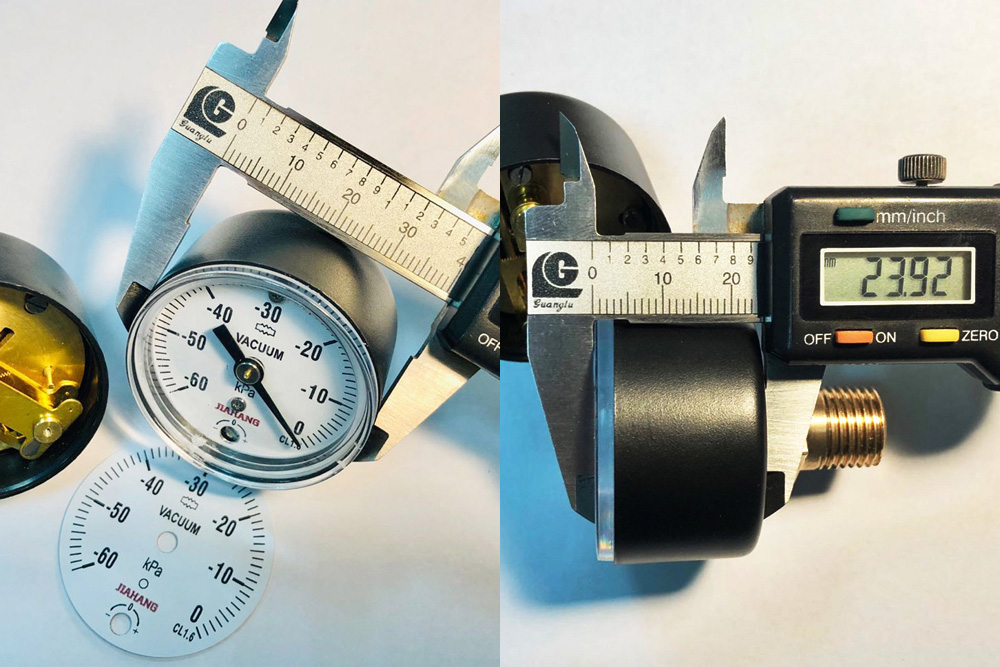

oem magnehelic differential pressure gauges

4. Versatility These gauges can measure both positive and negative pressures, making them incredibly versatile. They can be utilized across various applications, from monitoring air and gas flows to assessing filtration systems in clean labs.

5. Visual Readability The gauges feature a large, easy-to-read display that provides clear pressure readings at a glance. This is particularly beneficial in fast-paced environments where quick decision-making is crucial.

Applications of OEM Magnehelic Differential Pressure Gauges

The applications of OEM Magnehelic differential pressure gauges are vast and diverse. In HVAC systems, they monitor the pressure drop across filters, ensuring that air quality is maintained and systems operate efficiently. In clean room environments, these gauges help maintain specific pressure conditions, which are critical for manufacturing pharmaceuticals and microelectronics.

In the food and beverage industry, Magnehelic gauges aid in monitoring the pressure in various processes, ensuring compliance with health and safety standards. They are also used in laboratory settings to measure the integrity of containment systems, ensuring that hazardous materials do not leak into the surrounding environment.

Conclusion

OEM Magnehelic differential pressure gauges stand out as an essential component for various industries focusing on precision and reliability. Their ability to measure low-pressure differentials accurately, combined with their durability and ease of use, makes them a preferred choice for many applications. As industries continue to evolve and demand greater accuracy in their operations, the significance of these gauges will undoubtedly increase.

By investing in OEM Magnehelic differential pressure gauges, industries can enhance their productivity, ensure quality control, and ultimately provide safer environments for workers and consumers alike. Whether in HVAC systems, clean rooms, or industrial processes, these gauges are crucial for monitoring and managing pressure variations effectively.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025