Oct . 31, 2024 19:08 Back to list

OEM Low Range Differential Pressure Measurement Device for Various Applications

Understanding OEM Low Range Differential Pressure Gauges

Differential pressure gauges are essential instruments widely used in various industries, including HVAC, process control, and manufacturing. Among the different types of differential pressure gauges, OEM (Original Equipment Manufacturer) low range differential pressure gauges stand out due to their precision and reliability in measuring small pressure differences. This article delves into their significance, functionality, and applications.

What are Low Range Differential Pressure Gauges?

Low range differential pressure gauges are specifically designed to detect small variations in pressure between two points in a system. Typically, these gauges measure differences ranging from a few inches of water column (inH2O) to around 10 psi, making them ideal for applications where precise measurements are critical. OEM low range gauges are manufactured to meet the specific requirements of equipment builders and are often calibrated for accurate performance in specialized environments.

How Do They Work?

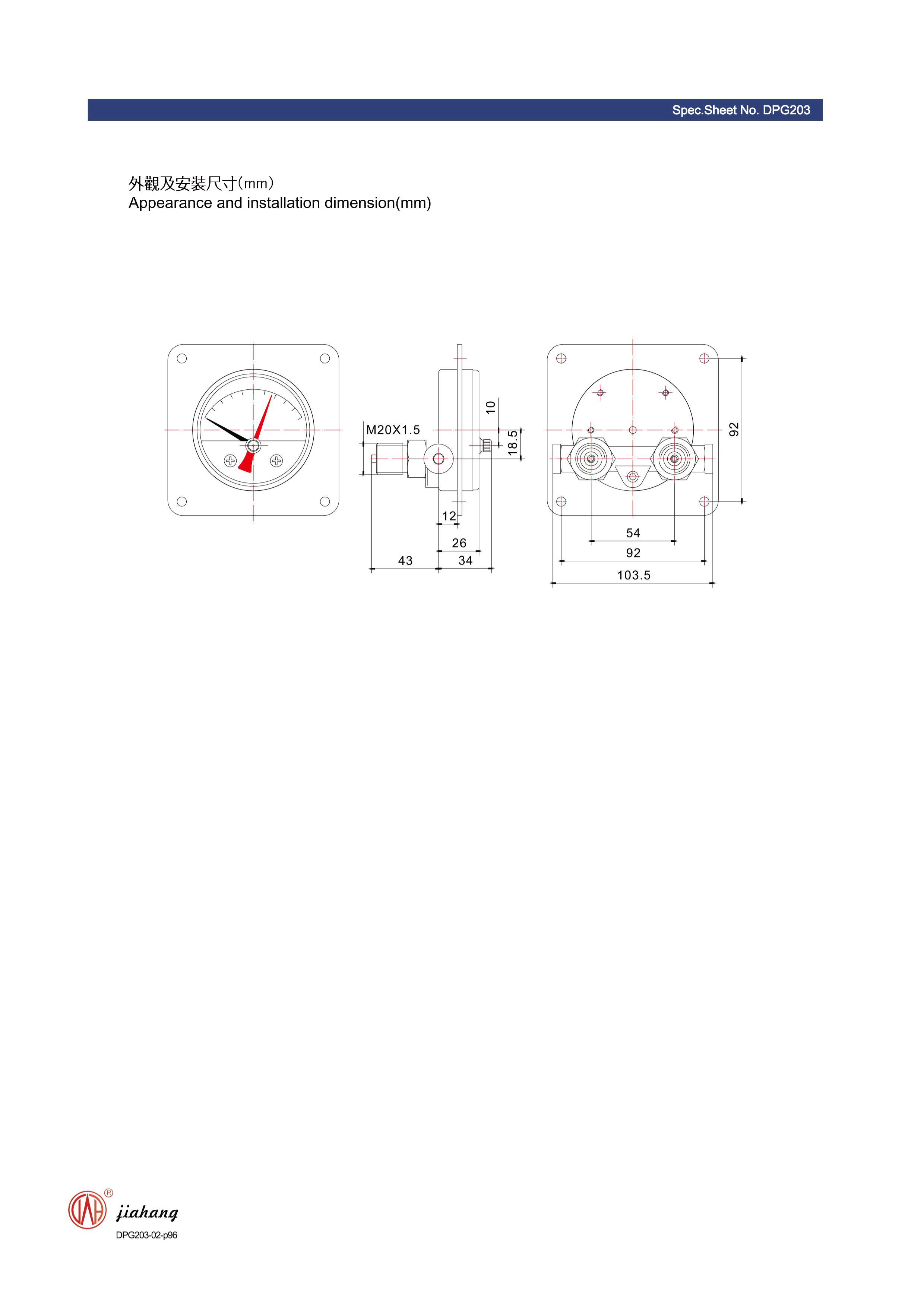

These gauges operate based on the principle of pressure sensing through a diaphragm or a Bourdon tube. The device features two pressure ports one connected to the point of higher pressure and the other to a reference point (typically atmospheric pressure or lower pressure). As the pressure in the system changes, the diaphragm flexes, causing a pointer to move on a calibrated scale. This movement translates the pressure differential into a readable value, providing operators with vital information about system performance.

oem low range differential pressure gauge

Applications of OEM Low Range Differential Pressure Gauges

OEM low range differential pressure gauges are utilized across various sectors. In HVAC systems, they monitor pressure drops across filters, ensuring optimal airflow and preventing equipment damage. In pharmaceutical and food processing industries, these gauges play a crucial role in maintaining cleanroom environments by controlling the differential pressure between clean areas and surrounding spaces.

Moreover, in manufacturing processes, these gauges help monitor and control fluid flow in pipelines. Anomalies in differential pressure readings can indicate blockages, leaks, or other issues, enabling timely maintenance and reducing downtime.

Benefits of Using OEM Low Range Differential Pressure Gauges

The advantages of using OEM low range differential pressure gauges are numerous. Firstly, they offer high accuracy, allowing for better process control and quality assurance. Secondly, their robust construction ensures durability, which is critical in harsh working environments. Additionally, OEM gauges often come with customization options, enabling manufacturers to tailor the instruments specifically to their equipment and applications.

In conclusion, OEM low range differential pressure gauges are indispensable tools in the modern industrial landscape. Their ability to measure minute pressure differences accurately supports optimal performance in various applications, from HVAC systems to high-precision manufacturing processes. As industries continue to evolve, the role of these gauges in ensuring safety, efficiency, and reliability will only become more pronounced. Investing in high-quality OEM gauges is a strategic move for any business aiming to maintain operational excellence and respond swiftly to potential issues.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025