Nov . 11, 2024 18:54 Back to list

oem fire system pressure gauge

Understanding OEM Fire System Pressure Gauges Importance, Functionality, and Maintenance

In fire protection systems, ensuring the efficacy of fire suppression and alarm mechanisms is paramount. One of the key components in these systems is the pressure gauge, specifically designed and manufactured by an Original Equipment Manufacturer (OEM). OEM fire system pressure gauges play a crucial role in monitoring the hydraulic performance of fire suppression systems, contributing to the overall safety and reliability of fire protection measures.

Importance of Pressure Gauges in Fire Systems

Pressure gauges are essential tools that provide vital information about the state of the fire suppression system. They measure the pressure of water or other firefighting agents in the system, indicating whether the system is functioning within its optimal operational limits. An accurate pressure reading helps confirm that sufficient pressure is available to deliver the necessary volume of firefighting agent during an emergency.

Installing OEM pressure gauges ensures compatibility and reliability within the fire suppression systems. OEM manufacturers create these instruments to meet stringent industry standards, ensuring that they can withstand the high pressures and rapid transitions typical in firefighting scenarios. By utilizing OEM gauges, system operators can trust that their equipment will perform effectively when it matters most.

Functionality of OEM Fire System Pressure Gauges

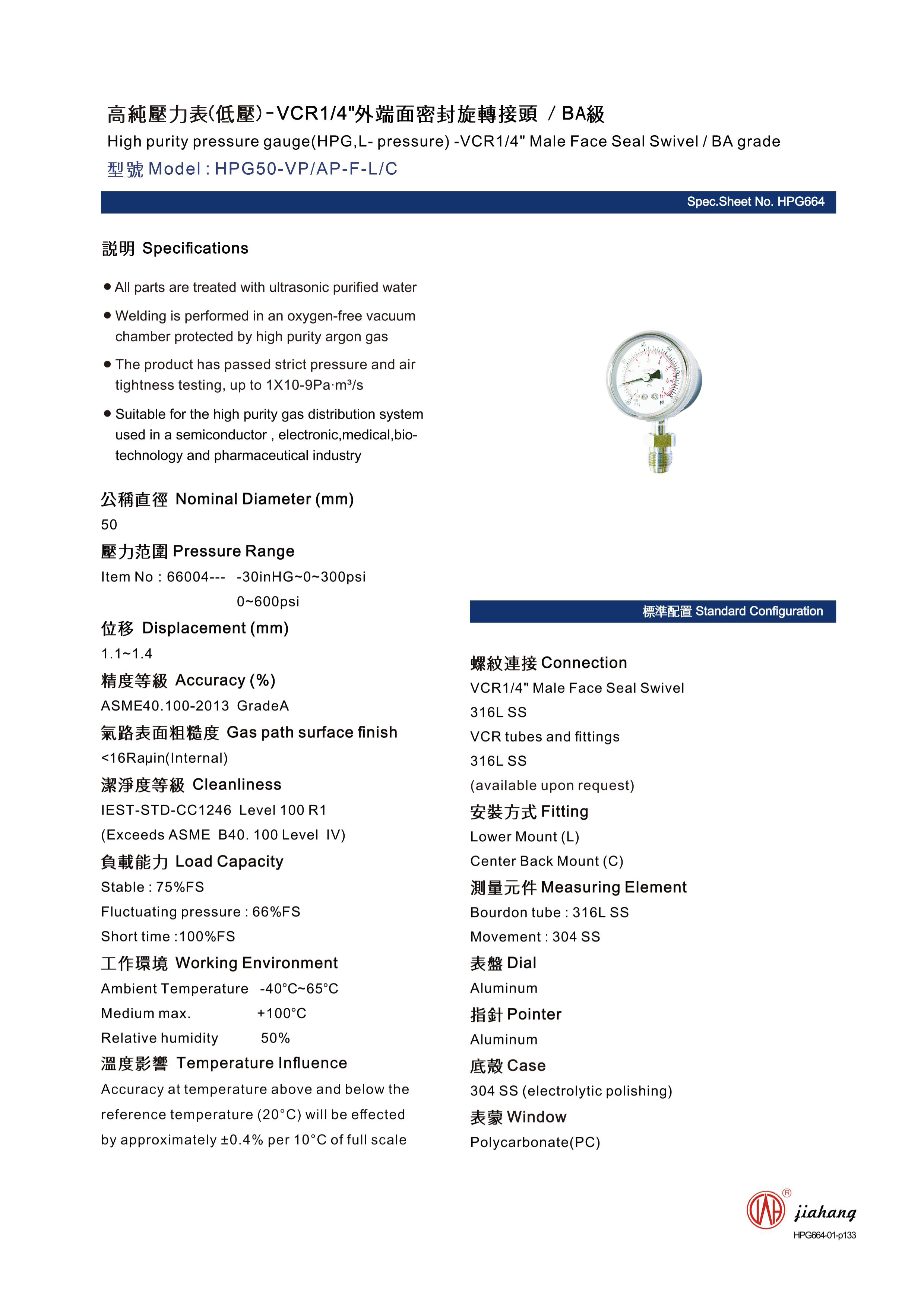

OEM fire system pressure gauges typically feature robust construction, ensuring longevity even in harsh environments. These gauges utilize various mechanisms, such as bourdon tube or diaphragm types, to accurately gauge pressure. When the pressure within the system increases, it causes the tube or diaphragm to deform, which then translates into a readable measurement on the gauge dial.

Most fire system pressure gauges are calibrated to display pressure in pounds per square inch (psi) or bar, allowing users to easily understand and assess the operational status of their fire protection systems. They can indicate both static pressure (the pressure in the system when no water is flowing) and dynamic pressure (the pressure while the system is under flow conditions).

Key Features of OEM Pressure Gauges

1. Durability OEM fire system pressure gauges are made from materials that resist corrosion and wear, making them suitable for various environmental conditions. This is particularly important when mounting gauges in fire pump rooms or outdoors.

oem fire system pressure gauge

2. Accuracy Precision is paramount in fire protection. OEM gauges are manufactured to precise standards to ensure reliable readings, which can be crucial for effective emergency response.

3. Safety Indicators Many OEM gauges come equipped with color-coded zones or markers that indicate safe and unsafe pressure ranges. This feature allows operators to quickly assess the status of the system and take necessary actions if the pressure falls outside of the acceptable range.

4. Ease of Installation These gauges are designed for straightforward installation and integration into existing systems, minimizing downtime and ensuring that fire protection systems are ready for immediate use.

5. Maintenance Alerts Advanced OEM pressure gauges may incorporate additional features such as automated alerts or integrate with monitoring systems to notify personnel of irregular pressure readings or maintenance needs.

Maintenance of Fire System Pressure Gauges

Maintaining pressure gauges is essential to ensure their reliability and accuracy. Routine inspections should involve checking the calibration of the gauge, ensuring it is within the manufacturer's specifications. Dust, debris, and corrosion can affect readings, so keeping the gauge clean and free from obstruction is vital.

Operators should also monitor for signs of wear and tear, such as fluctuating pressure readings or physical damage to the gauge. Regular maintenance allows for timely replacements, which can prevent system failures during critical moments, ensuring that the fire suppression system remains reliable.

Conclusion

OEM fire system pressure gauges are integral components of any fire protection system, providing essential data that helps safeguard lives and property. By understanding their importance, functionality, and needs for maintenance, facility managers can ensure their fire suppression systems remain effective and reliable. Ultimately, using high-quality OEM pressure gauges contributes to a more robust fire safety protocol, making it an indispensable aspect of modern fire protection strategies.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025