Oct . 13, 2024 11:22 Back to list

Components Used in OEM Digital Pressure Gauge Systems for Accurate Measurement

Understanding OEM Digital Pressure Gauge Components

In the realm of industrial measurement and control, precision is paramount. One of the most significant instruments used for measuring pressure in various applications is the digital pressure gauge. Particularly, Original Equipment Manufacturers (OEMs) play a crucial role in the design and fabrication of these devices and their components. Understanding the components of OEM digital pressure gauges not only helps in comprehending their functionality but also aids in making informed decisions regarding their application.

Core Components of Digital Pressure Gauges

Digital pressure gauges are comprised of several essential components that work together to provide accurate pressure readings. The primary components include

1. Pressure Sensor At the heart of any digital pressure gauge is the pressure sensor. This component detects the pressure of the fluid or gas within a system, converting it into an electrical signal. Various types of sensors are used, including piezoelectric, strain gauge, and capacitive sensors, each having unique principles of operation and applicability depending on the required accuracy and range.

2. Signal Conditioning Circuit The raw output from the pressure sensor often requires conditioning to be usable. The signal conditioning circuit amplifies, filters, and converts the sensor’s analog signal into a digital format. This step is crucial for ensuring that the data is accurate and reliable, minimizing noise or interference that could affect the readings.

3. Analog-to-Digital Converter (ADC) This component plays a pivotal role in transforming the conditioned analog signal into a digital signal that can be processed and displayed. A high-resolution ADC is important for achieving precise measurements, enabling the digital gauge to provide accurate readings over varying pressure ranges.

4. Microcontroller The microcontroller is essentially the brain of the digital pressure gauge. It processes the digital signals from the ADC, executes algorithms for calculations, and manages the display. Modern microcontrollers often come equipped with integrated connectivity options, allowing for communication with other devices or systems.

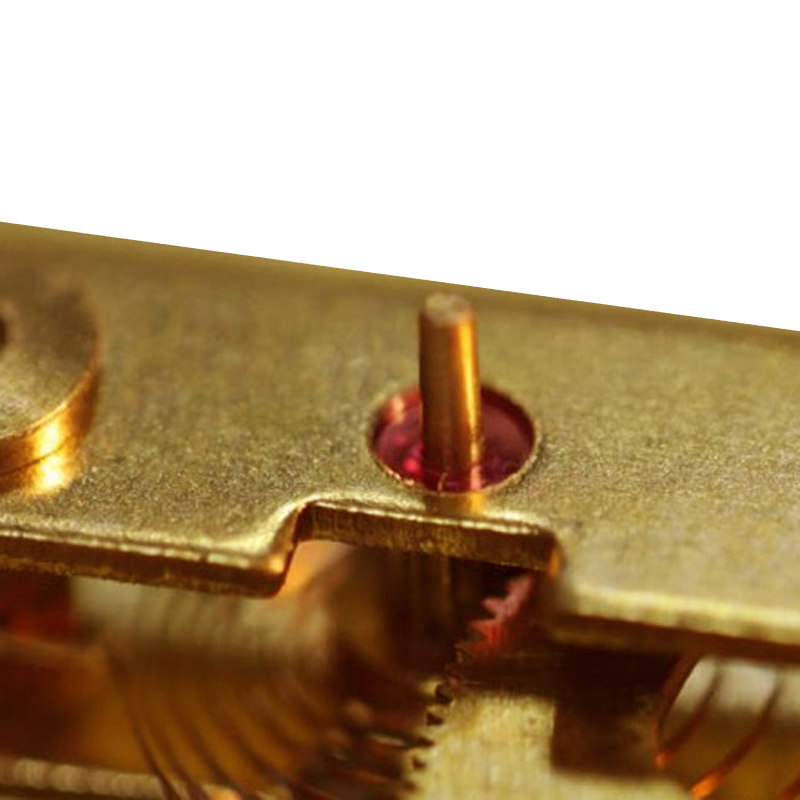

oem digital pressure gauge components

5. Display The display presents the measured pressure in a readable format, typically using LCD or LED technologies. Many digital pressure gauges also provide additional information such as units of measurement, battery status, and other diagnostic information. The display is designed for clarity and ease of use, often featuring backlighting for visibility in low-light conditions.

6. Power Supply Digital pressure gauges require a power source, which can come from batteries, mains electricity, or even solar panels. The choice of power supply impacts the portability and functionality of the gauge.

7. Housing and Protection The casing of a digital pressure gauge is an often-overlooked but crucial component. It protects the internal components from environmental factors such as moisture, dust, and mechanical impacts. The material and design of the housing can significantly affect the device's durability and suitability for various applications, including harsh industrial environments.

Applications and Implications

OEM digital pressure gauges are vital in numerous industries, including oil and gas, pharmaceuticals, food and beverage, and manufacturing. Their precision and reliability enable industries to monitor processes effectively, ensuring safety and efficiency. For OEMs, understanding these components solidifies their ability to innovate and improve their products continually.

Conclusion

In summary, OEM digital pressure gauges are composed of various vital components that work harmoniously to offer precise pressure measurements. Familiarity with these components is essential for anyone involved in the selection, manufacturing, or application of these instruments. As technology advances, the evolution of digital pressure gauges promises even greater accuracy and functionality, further enhancing their role in modern industrial applications.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025