Dec . 29, 2024 03:22 Back to list

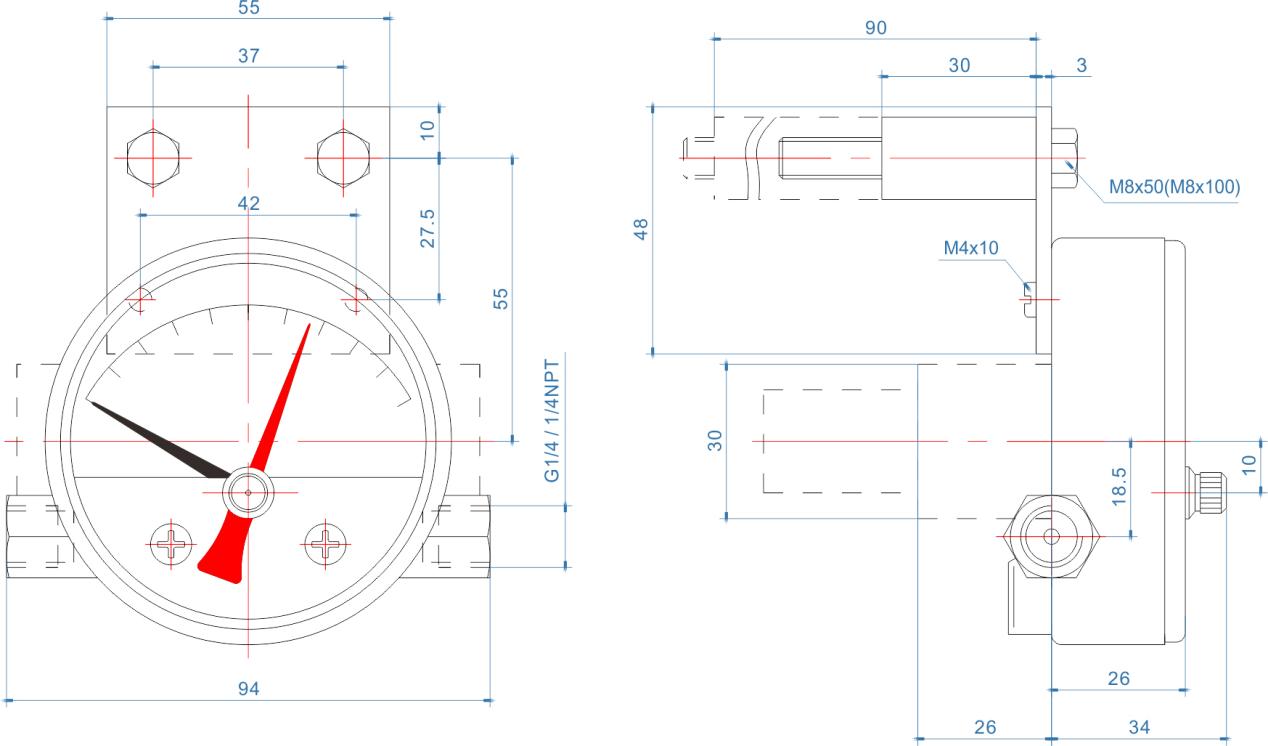

oem differential pressure gauge with sealed capilary

Understanding OEM Differential Pressure Gauges with Sealed Capillary

In the world of industrial measurement and instrumentation, maintaining precise control over pressure differentials is crucial for ensuring efficient operation and safety across various applications. OEM (Original Equipment Manufacturer) differential pressure gauges with sealed capillary systems are essential tools designed to measure and monitor the pressure difference between two points in a system. These devices are widely utilized in industries such as chemical processing, oil and gas, water treatment, and HVAC (Heating, Ventilation, and Air Conditioning).

What is a Differential Pressure Gauge?

A differential pressure gauge is a device that measures the difference in pressure between two points in a system. Unlike standard pressure gauges that measure absolute or gauge pressure, differential pressure gauges provide critical information about the flow and pressure variations in various fluids, whether liquids or gases. This differential reading allows operators to detect blockages, system inefficiencies, or potential equipment failures, ensuring that systems run smoothly and safely.

The Role of Sealed Capillaries

One of the key features of OEM differential pressure gauges is their incorporation of sealed capillary tubes. These capillaries serve as a conduit for transmitting pressure signals from the measurement points to the gauge itself. The sealed design prevents contamination and external influences from affecting the accuracy of the readings. Additionally, it minimizes the risk of fluid loss, which can occur in environments where the pressure changes rapidly.

Sealed capillaries are particularly beneficial in applications where the media being measured may be corrosive, viscous, or contain particulates. By isolating the measuring element from the process fluid, these capillaries help to prolong the lifespan of the gauge and maintain its reliability.

Advantages of OEM Differential Pressure Gauges

oem differential pressure gauge with sealed capilary

2. Versatility These gauges can be utilized in a variety of applications, including monitoring filters, pressure drop across orifices, and liquid level measurements in tanks.

3. Robust Design OEM gauges are often designed to withstand harsh industrial environments, featuring durable materials that resist corrosion and physical damage.

4. Ease of Installation Many OEM differential pressure gauges come with easy installation guidelines and mounting options, making them user-friendly even for those with limited technical expertise.

5. Real-time Monitoring The ability to monitor pressure differences in real-time allows industries to respond promptly to any changes, reducing the risk of downtime or system failures.

Applications in Industry

The applications of OEM differential pressure gauges with sealed capillaries are vast. In the chemical processing industry, these gauges are used to monitor the pressure differentials in reactors and separators. In HVAC systems, they are employed to ensure proper airflow and filter performance, which is essential for maintaining air quality and system efficiency. Additionally, in the oil and gas sector, differential pressure gauges help monitor pressure drops across pipelines, ensuring safe fluid transport and system integrity.

Conclusion

In summary, OEM differential pressure gauges equipped with sealed capillary systems play a vital role in the accurate measurement of pressure differentials across various sectors. Their high reliability, versatility, and robust design make them indispensable tools for operators aiming to enhance safety, efficiency, and performance in their operations. As industries continue to evolve, the demand for accurate and dependable measurement instruments like differential pressure gauges will undoubtedly grow, emphasizing the importance of these devices in fostering technological advancement and operational excellence. Understanding their features and applications is essential for any professional looking to optimize their industrial processes.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025