Nov . 06, 2024 13:45 Back to list

OEM Differential Pressure Gauge Distributor for Optimal Measurement Solutions and Industrial Applications

Understanding OEM Differential Pressure Gauges A Guide for Distributors

In various industrial applications, the accurate measurement of pressure is crucial for ensuring safe and efficient operations. One key instrument used in this area is the differential pressure gauge. These devices play a pivotal role in monitoring pressure differences within systems, which can be indicative of performance, efficiency, and overall system health. For distributors, understanding the nuances of Original Equipment Manufacturer (OEM) differential pressure gauges is essential to cater to the needs of end-users effectively.

What Are OEM Differential Pressure Gauges?

OEM differential pressure gauges are specialized instruments fabricated by manufacturers specifically for original equipment applications. Unlike standard gauges, these devices are often tailored to meet the unique specifications and requirements of particular machines or systems. Such customization can involve varied pressure ranges, materials, and connections, making them integral to the functioning of many industrial processes.

The primary function of a differential pressure gauge is to measure the difference in pressure between two points in a system. This function is crucial in applications like filtration monitoring, flow measurement, and level measurement. By providing accurate readings, these gauges help in optimizing operations and preventing potential issues such as equipment failure or inefficiency in processes.

Key Features of OEM Differential Pressure Gauges

1. Precision Measurement OEM differential pressure gauges are designed to offer high accuracy in measurement. This precision is vital in applications where even a small deviation from normal pressure differentials can lead to significant consequences.

2. Robust Construction Given the harsh environments in which they are often used, these gauges are built with durability in mind. They typically feature rugged materials that can withstand corrosive substances, extreme temperatures, and high levels of vibration.

3. Customized Design One of the standout features of OEM differential pressure gauges is their ability to be tailored for specific applications. This customization can include various diaphragm materials, casing designs, and connection types, ensuring compatibility with a wide range of equipment.

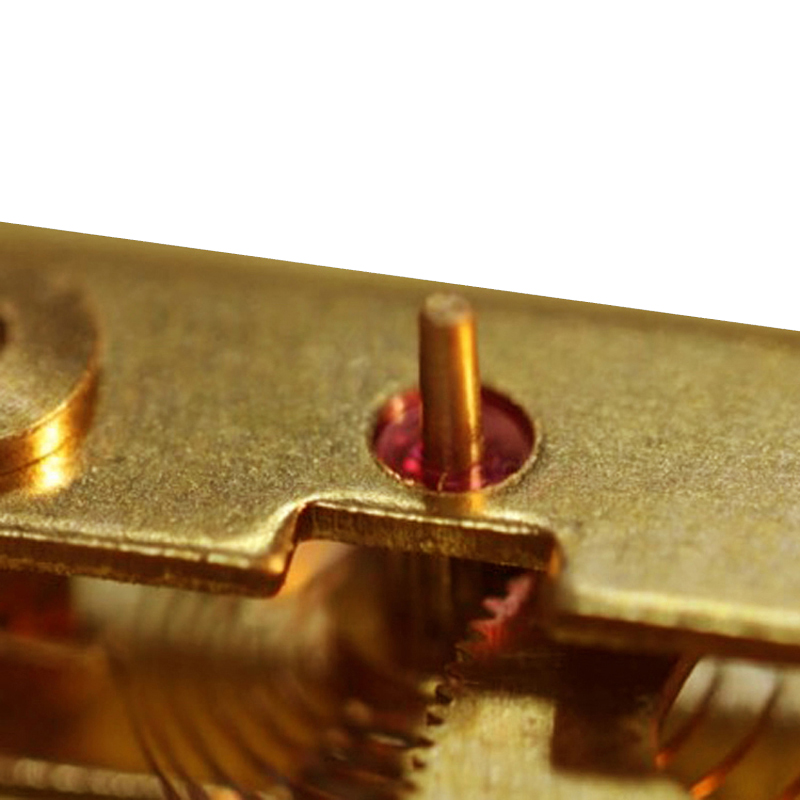

oem differential pressure gauges distributor

4. Ease of Integration These gauges are designed for seamless integration into existing systems. Distributors should highlight the compatibility features of OEM gauges, which can help users avoid extensive modifications during installation.

5. Wide Applicability OEM differential pressure gauges find applications across various industries, including HVAC, water treatment, pharmaceuticals, and oil and gas. This versatility allows distributors to cater to a broad customer base.

Challenges Faced by Distributors

Distributors of OEM differential pressure gauges face several challenges, including competition from generic gauge manufacturers and the need to maintain a comprehensive inventory of specialized products. Knowledge of product specifications and application suitability is essential for distributors to effectively advise customers on the best options. Providing educational resources and technical support can differentiate a distributor in the marketplace.

The Importance of Customer Relationships

Building strong relationships with customers is crucial for distributors of OEM differential pressure gauges. Understanding the specific needs and challenges of clients allows distributors to recommend suitable products and respond effectively to inquiries. Regular communication and follow-up can help in identifying new opportunities and ensuring customer satisfaction.

Conclusion

OEM differential pressure gauges are vital tools in many industrial applications, offering precise and reliable pressure measurements essential for optimal system performance. For distributors, grasping the key features, challenges, and customer relationship strategies regarding these gauges can enhance their market position. By emphasizing the benefits of OEM products and providing comprehensive support to clients, distributors can ensure they meet the growing demands of diverse industries while establishing themselves as trusted partners in operational safety and efficiency.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025