Dec . 03, 2024 15:17 Back to list

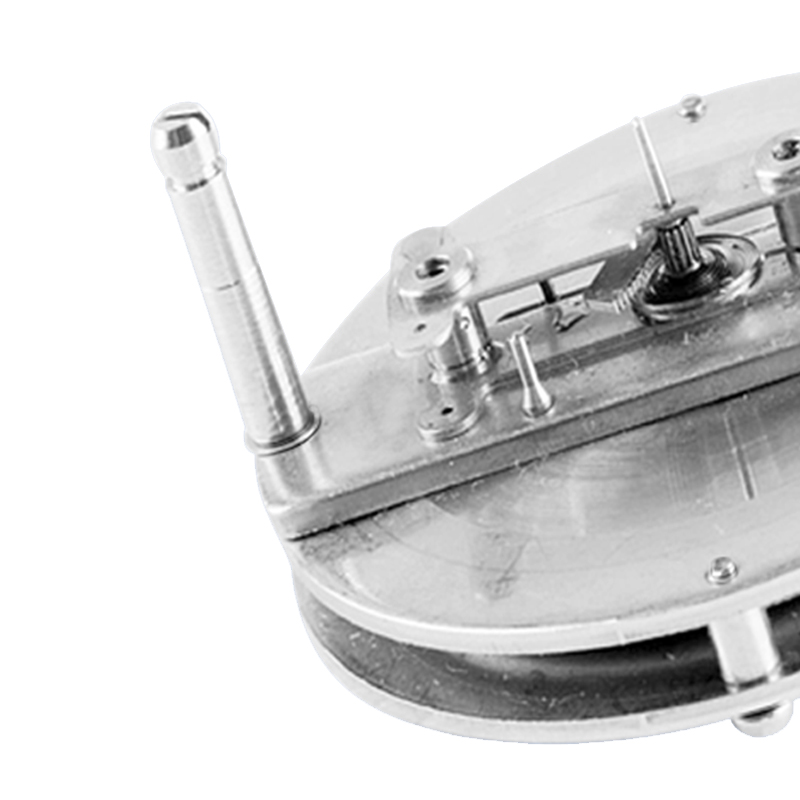

oem differential pressure gauge in pharma industry

The Importance of OEM Differential Pressure Gauges in the Pharmaceutical Industry

In the pharmaceutical industry, maintaining the highest standards of quality and safety is paramount. One crucial aspect of this commitment involves careful monitoring and control of various parameters in production processes, with pressure differentials being a key focus. As such, OEM (Original Equipment Manufacturer) differential pressure gauges have become indispensable tools in ensuring compliance with regulatory requirements and optimizing operational efficiency.

Differential pressure gauges are instruments that measure the difference in pressure between two points in a system. In the pharmaceutical sector, they play a vital role in a variety of applications, including monitoring air filters, cleanrooms, and processing equipment. These gauges provide critical data that can indicate the performance and integrity of systems designed to ensure product purity and prevent contamination.

One of the primary applications of differential pressure gauges in the pharmaceutical industry is in monitoring air filtration systems. High-efficiency particulate air (HEPA) filters are commonly employed to provide clean air in manufacturing and laboratory settings. Differential pressure gauges measure the pressure drop across these filters, allowing operators to assess their performance and determine when maintenance or replacement is required. A significant increase in pressure differential may indicate that the filter is clogged, which could lead to inadequate air quality and, consequently, product contamination.

Moreover, in sterile areas such as cleanrooms, maintaining appropriate pressure differentials is essential to prevent contamination from outside environments. Differential pressure gauges help ensure that clean areas are maintained under positive pressure relative to adjacent areas, thereby preventing the ingress of particulates and microbes. By continuously monitoring these pressure levels, pharmaceutical facilities can adhere to strict regulatory guidelines and ensure product safety and efficacy.

oem differential pressure gauge in pharma industry

In addition to ensuring compliance with industry standards, OEM differential pressure gauges are engineered for accuracy and reliability, essential criteria in the pharmaceutical field. OEM manufacturers often design these instruments to withstand the rigors of pharmaceutical environments, which may involve exposure to harsh chemicals and extreme temperatures. High-quality materials and advanced technology in the design and manufacturing processes contribute to the longevity and precision of these gauges.

Another significant factor is the calibration and validation of these instruments. In a regulated industry like pharmaceuticals, it is not enough for differential pressure gauges to merely function correctly; they must also be calibrated to ensure their readings are accurate. OEM suppliers often provide essential services such as onsite calibration, validation, and maintenance, facilitating compliance with Good Manufacturing Practices (GMP) and other regulations.

The selection of an OEM differential pressure gauge is not just about purchasing an instrument; it involves choosing a reliable partner who understands the specific needs of the pharmaceutical industry. Factors such as gauge range, sensor technology, and compatibility with existing systems should all be considered. Furthermore, OEMs are often able to provide additional support, including training for personnel, which enhances the overall effectiveness and reliability of the measurement system.

In conclusion, OEM differential pressure gauges are vital components in the pharmaceutical industry, helping to ensure the safety and quality of products through diligent monitoring and regulation of pressure differentials. By enabling effective filtration system management, maintaining cleanroom integrity, and providing reliable and accurate measurements, these instruments play a crucial role in fostering an environment where pharmaceutical products can be produced in compliance with the highest standards. As the industry continues to evolve, the importance of integrating innovative and reliable measurement tools remains a top priority for pharmaceutical manufacturers worldwide.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025