Oct . 17, 2024 02:56 Back to list

oem diaphragm seal pressure gauges

Understanding OEM Diaphragm Seal Pressure Gauges A Comprehensive Overview

In various industries ranging from oil and gas to pharmaceuticals, accurate pressure measurement is critical to maintaining operational efficiency and safety. One of the essential tools for this task is the diaphragm seal pressure gauge. This article explores the significance, functionality, and advantages of OEM diaphragm seal pressure gauges, shedding light on why they are indispensable in industrial applications.

What is a Diaphragm Seal Pressure Gauge?

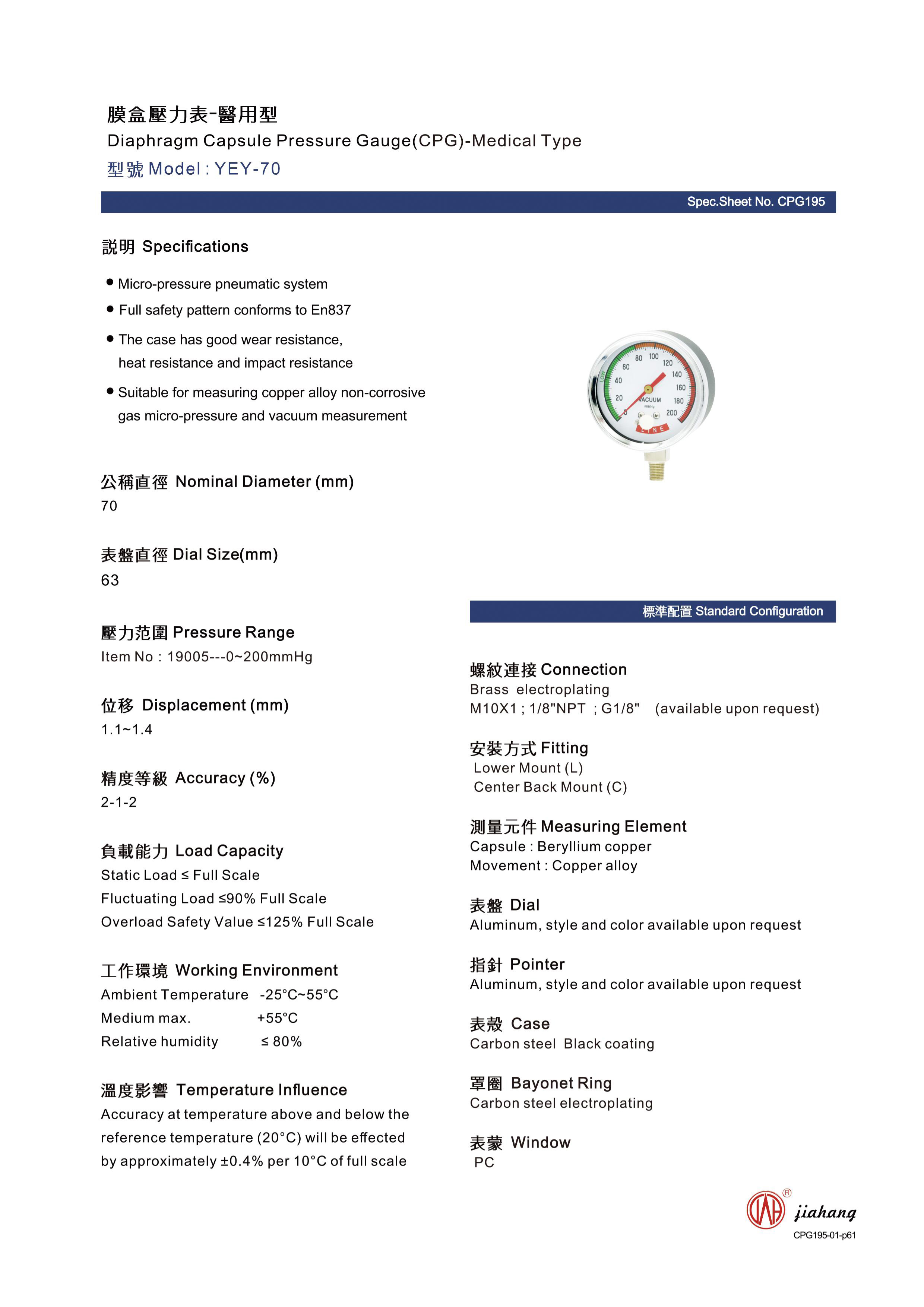

A diaphragm seal pressure gauge is a specialized type of pressure measuring device that utilizes a flexible diaphragm to isolate the sensing element from the process fluid. This design is particularly beneficial when measuring the pressure of corrosive, viscous, or high-temperature fluids. The diaphragm essentially acts as a barrier, allowing the gauge to function without direct exposure to potentially damaging materials.

Components and Operation

At the core of a diaphragm seal pressure gauge are two primary components the diaphragm itself and the pressure gauge. Here’s a closer look at how they work together

1. Diaphragm Typically made from resilient materials like stainless steel, Teflon, or other compatible alloys, the diaphragm flexes in response to pressure changes. This deformation transmits the applied pressure to the sensing element.

2. Pressure Gauge This part, which can be analog or digital, measures the deflection of the diaphragm and translates it into a readable pressure value. The gauge's face displays the measurement, often with various calibrations depending on the application’s needs.

Benefits of Using Diaphragm Seal Pressure Gauges

1. Protection Against Corrosion and Contamination One of the most crucial advantages of diaphragm seal pressure gauges is their protective barrier against corrosive or contaminated fluids. This feature significantly enhances the instrument's longevity and reliability, especially in harsh environments.

oem diaphragm seal pressure gauges

2. Versatility Diaphragm seal pressure gauges are versatile instruments suitable for various applications, including those involving slurries, viscous fluids, and high temperatures. By choosing different diaphragm materials and seal designs, these gauges can be customized to meet specific process requirements.

3. Accurate Measurements The design of diaphragm seals can enhance the accuracy of pressure readings. They help minimize the impact of pulsations and vibrations, thus providing more stable and precise measurements.

4. Ease of Maintenance Many OEM diaphragm seal pressure gauges are designed with a focus on ease of maintenance. Their construction often allows for straightforward cleaning and recalibration, which is essential for industries where hygiene and accuracy are paramount.

5. Safety Maintaining safe operational conditions is crucial in many industries. Diaphragm seal pressure gauges minimize the risk of leaks or failures, thus protecting both personnel and equipment from potential hazards associated with high-pressure systems.

Customization and OEM Solutions

Original Equipment Manufacturers (OEMs) play a vital role in the production of diaphragm seal pressure gauges. They can provide tailored solutions that meet specific industry standards or customer demands. Customizations might include variations in size, pressure ranges, materials, and additional features such as remote sensing or electronic outputs.

Conclusion

Diaphragm seal pressure gauges are a critical tool in today’s industrial landscape. Through their unique design, they ensure accurate pressure measurement while protecting sensitive components from harsh process conditions. Their versatility, safety, and ease of maintenance make them ideal for various applications. With the added benefit of OEM solutions, industries can access tailored instruments designed to meet their specific requirements.

As operational complexities and demands continue to evolve, the importance of reliable pressure measurement will only grow. Investing in high-quality diaphragm seal pressure gauges is not just an operational choice; it is a commitment to safety, efficiency, and precision in industrial processes. Whether in a refinery, a pharmaceutical plant, or any other critical environment, these gauges stand out as indispensable tools for success.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025