Oct . 11, 2024 09:48 Back to list

oem diaphragm pressure gauge manufacturer

Understanding OEM Diaphragm Pressure Gauge Manufacturers

In industrial applications, the accurate measurement of pressure is critical for ensuring safety, efficiency, and reliability. Among the various types of pressure measuring devices available, diaphragm pressure gauges are widely used due to their robustness and precision. This article explores the role of Original Equipment Manufacturer (OEM) diaphragm pressure gauge manufacturers, their significance in various industries, and what to consider when choosing these devices.

What is a Diaphragm Pressure Gauge?

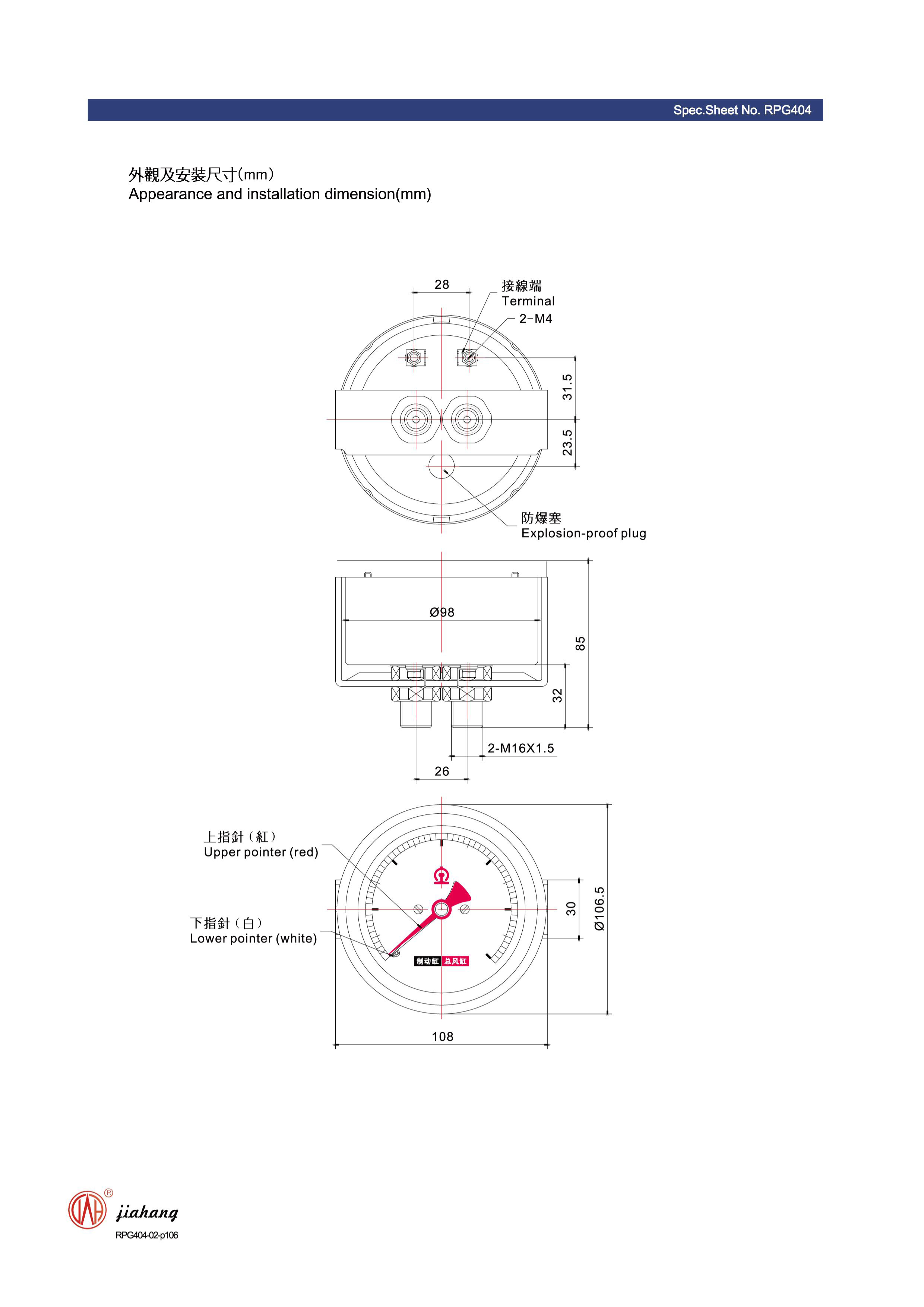

A diaphragm pressure gauge is an instrument used to measure the pressure of gases and liquids. It operates using a flexible diaphragm that deforms in response to pressure changes. This deformation is then converted into a mechanical movement that drives the pointer on the gauge dial, providing a direct reading of pressure. Such gauges are highly valuable in industries where space is limited and precise measurements are necessary.

The Role of OEM Manufacturers

OEM diaphragm pressure gauge manufacturers play a pivotal role in the supply chain of pressure measurement devices. Unlike standard manufacturers, OEMs focus on producing components and equipment that may be integrated into another company's product. This means that they often tailor their designs to meet the specific needs and standards of their clients, offering customization options that enhance functionality and performance.

Industries Relying on OEM Diaphragm Pressure Gauges

1. Oil and Gas In the oil and gas sector, reliable pressure measurement is crucial for monitoring pipeline integrity, drilling operations, and refining processes. OEM diaphragm pressure gauges can withstand extreme conditions, including high temperatures and corrosive environments, making them ideal for this industry.

2. Pharmaceuticals The pharmaceutical industry demands stringent compliance with safety standards and regulations. Diaphragm pressure gauges used in this sector must be capable of handling sterile conditions without contamination. OEM manufacturers often design their products with hygienic features that are essential for pharmaceutical applications.

3. Food and Beverage Similar to the pharmaceutical industry, the food and beverage sector requires precise measurements to ensure product quality and safety. OEM manufacturers provide diaphragm pressure gauges that resist corrosion and are easy to clean, maintaining the hygiene standards required in food processing.

oem diaphragm pressure gauge manufacturer

4. Manufacturing and Automation In manufacturing environments, maintaining optimal pressure in hydraulic and pneumatic systems is vital. OEM diaphragm pressure gauges can be integrated into automated systems, allowing for real-time monitoring and control, thereby improving operational efficiency.

Choosing the Right OEM Manufacturer

When selecting an OEM diaphragm pressure gauge manufacturer, several factors should be considered

- Quality Assurance Look for manufacturers adhering to international quality standards such as ISO 9001. Quality assurance processes ensure that the products meet the necessary specifications and regulations.

- Customization Options Choose an OEM that offers customization capabilities. This includes variations in diaphragm materials, gauge ranges, and connection types to suit specific applications.

- Technical Support Opt for manufacturers that provide comprehensive technical support to assist with installation, calibration, and maintenance. Good customer service can significantly reduce downtime in critical operations.

- Reputation and Experience Research the manufacturer's reputation in the industry. A well-established company with a track record of reliable products is more likely to meet your needs.

Conclusion

OEM diaphragm pressure gauge manufacturers are essential providers of precision measurement instruments across various industries. Their ability to deliver customized solutions ensures that businesses can achieve optimal performance and safety in their operations. When selecting an OEM partner, businesses should emphasize quality, customization, and support to meet their unique pressure measurement requirements. By making informed decisions, companies can enhance their operational efficiency and maintain high standards of safety and reliability.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025