Sep . 12, 2024 07:26 Back to list

OEM Fire Engine Pressure Gauge - High-Precision Measurement Tools

Understanding OEM Fire Engine Pressure Gauges

Firefighting is a high-stakes profession where every piece of equipment plays a crucial role in ensuring safety and effectiveness during emergencies. One such essential tool is the fire engine pressure gauge, particularly the Original Equipment Manufacturer (OEM) versions. These gauges are vital for monitoring the pressure in the fire engine's water pump system, which can significantly impact firefighting efforts.

Importance of Pressure Gauges

In firefighting, water pressure is paramount. It influences both the reach and impact of water jets on flames. An OEM fire engine pressure gauge provides accurate readings of the pump’s output pressure, allowing firefighters to make informed decisions while battling fires. A well-functioning pressure gauge helps ensure that the fire engine operates within optimal parameters, maximizing both efficiency and safety.

Features of OEM Pressure Gauges

OEM fire engine pressure gauges are designed with specific features tailored to the demanding environment of firefighting. These gauges are built to withstand extreme conditions, including high temperatures and vibrations, which are common during firefighting operations. Many OEM pressure gauges come equipped with shock-resistant casings, ensuring reliability under pressure.

Additionally, these gauges typically provide easy-to-read displays, often featuring large, clear markings for quick reference during intense situations. The accuracy of OEM gauges is key; even small discrepancies in pressure readings can lead to ineffective firefighting measures.

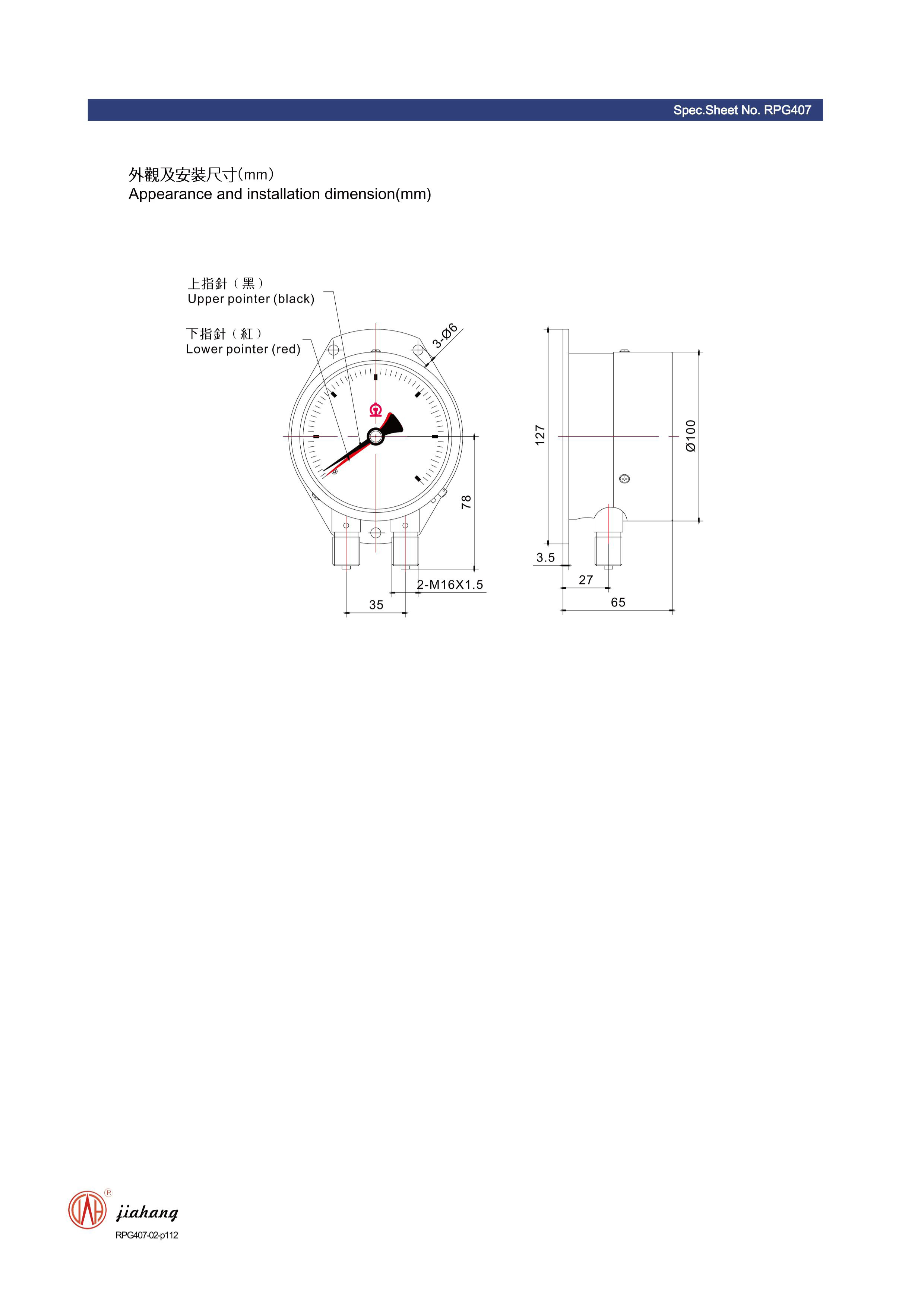

oem fire engine pressure gauge

Calibration and Maintenance

To function effectively, fire engine pressure gauges must be properly calibrated and regularly maintained. OEM manufacturers often recommend specific calibration schedules to ensure the gauges deliver precise readings. Maintenance can involve routine inspections and servicing by certified professionals to check for wear and tear, as well as replacing any faulty components.

The Role of Technology

With advancements in technology, many modern fire engines are now equipped with digital pressure gauges. These can offer additional features such as automatic data logging, allowing firefighters to track pressure changes over time. However, regardless of whether a gauge is analog or digital, the integrity of OEM parts remains critical, as they are specifically designed to work seamlessly with the fire engine’s systems.

Conclusion

In summary, OEM fire engine pressure gauges are indispensable components of a fire engine's pump system. They provide essential data that influences firefighting strategies and outcomes. By ensuring that these gauges are accurate, well-maintained, and supported by the best technology, firefighting professionals can enhance their operational effectiveness and improve safety measures during emergencies. More than just tools, these gauges represent a commitment to excellence in the high-stakes world of firefighting, where every second and every drop of water counts. As the firefighting landscape continues to evolve, the role of reliable and precise pressure gauges will remain a cornerstone of effective fire suppression efforts.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025