Sep . 28, 2024 06:37 Back to list

Understanding the Functionality of ODM Vacuum Differential Pressure Gauges in Industrial Applications

Understanding ODM Vacuum Differential Pressure Gauges

In today's fast-paced industrial environments, precise measurement of pressure is crucial for ensuring operational efficiency and product quality. One essential tool in this domain is the ODM vacuum differential pressure gauge. This specialized instrument plays a vital role in various applications, providing accurate readings that help maintain optimal conditions in vacuum processes.

What is a Vacuum Differential Pressure Gauge?

A vacuum differential pressure gauge is designed to measure the difference in pressure between two points, typically one of which is at or near vacuum conditions. It operates by comparing the pressure in a vacuum chamber to the ambient atmospheric pressure or another reference point. These gauges are essential in processes where maintaining a specific pressure differential is critical, such as in cleanrooms, chemical processing, and HVAC systems.

How Does an ODM Vacuum Differential Pressure Gauge Work?

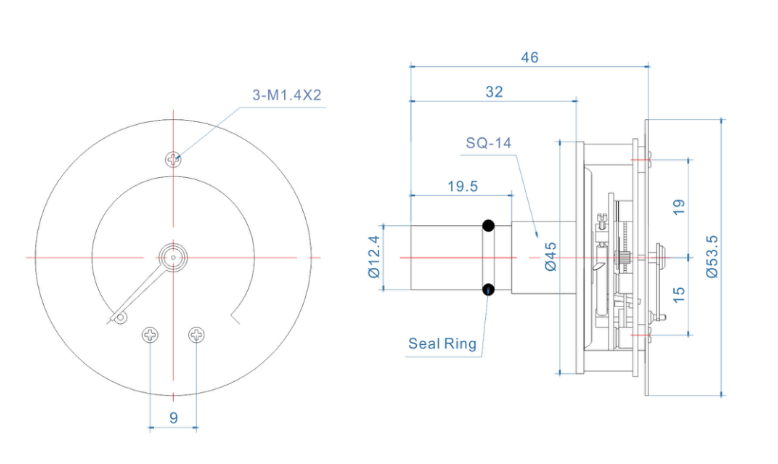

The core working principle of an ODM vacuum differential pressure gauge revolves around the use of a sensing element, usually consisting of a diaphragm or tube that reacts to pressure changes. When the pressure at one input rises or falls, the diaphragm deflects, which, in turn, moves a pointer across a calibrated scale, indicating the differential pressure.

The gauge may be equipped with electronic sensors that enable digital output for enhanced accuracy and data logging capabilities. Such tools can interface with computer systems to allow for real-time monitoring and control, thereby improving responsiveness in industrial processes.

Applications of ODM Vacuum Differential Pressure Gauges

1. Pharmaceutical Industry In the pharmaceutical sector, maintaining the right pressure balance is critical for processes like sterile filling, where contamination risks must be minimized. ODM vacuum differential pressure gauges are used to monitor and control pressure levels in cleanrooms and isolators, ensuring compliance with stringent health regulations.

2. Food Processing Maintaining vacuum conditions during packaging or processing is essential for food safety and shelf-life. These gauges help regulate and monitor the vacuum levels within sealed environments, preventing spoilage and ensuring that products meet quality standards.

odm vacuum differential pressure gauge

3. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, differential pressure gauges monitor airflow and filter conditions. They ensure that systems operate efficiently, preventing energy wastage and maintaining comfort levels in buildings.

4. Chemical Processing In chemical manufacturing, the accurate measurement of pressure differentials can prevent hazardous leaks and ensure safe operation conditions. ODM vacuum differential pressure gauges are instrumental in monitoring reactor pressure, filtration, and distillation processes.

Benefits of Using ODM Vacuum Differential Pressure Gauges

- High Precision ODM gauges offer superior accuracy, which is crucial for critical applications where small pressure changes can have significant impacts.

- Durability Built to withstand rigorous conditions, these gauges are often constructed from robust materials that resist corrosion and wear, ensuring longevity even in demanding environments.

- User-Friendly With both analog and digital models available, ODM vacuum differential pressure gauges cater to diverse user needs. Digital models often feature intuitive displays and connectivity for seamless integration with modern monitoring systems.

- Versatility ODM gauges can be used across various sectors, providing flexibility in measurement and a broad range of applications. They can handle different media and pressure ranges, making them suitable for various industrial needs.

Conclusion

In conclusion, ODM vacuum differential pressure gauges are indispensable tools in many industrial applications where maintaining precise pressure is vital to product quality and process safety. With their robust design, high accuracy, and adaptability, they facilitate efficient monitoring and control in environments where precision is paramount. As industries continue to evolve, the importance of such measurement devices will undoubtedly grow, reinforcing their role as fundamental components of modern industrial systems. Understanding and implementing these gauges can lead to improved reliability, safety, and efficiency across various applications.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025