Dec . 07, 2024 18:31 Back to list

odm railway pressure gauge

Understanding ODM Railway Pressure Gauges Enhancing Safety and Performance

The transportation industry heavily relies on various technologies to ensure safety and efficiency. One such vital technology in the railway sector is the railway pressure gauge, particularly those developed by ODM (Original Design Manufacturer). This article delves into the significance of ODM railway pressure gauges, their design, functionality, and impact on railway operations.

The Importance of Pressure Gauges in Railways

Pressure gauges are critical components in many industrial applications, including the railway sector. They measure the pressure of fluids and gases, providing essential data that influences operational decisions. In the context of railways, pressure gauges are used to monitor brake systems, fuel systems, and air systems, ensuring that trains operate within safe pressure limits. Accurate pressure readings are vital for preventing mechanical failures, breaches of safety protocols, and enhancing overall performance.

ODM’s Role in Pressure Gauge Manufacturing

ODM companies specialize in creating personalized products tailored to the specific needs of their clients. In the railway industry, ODM pressure gauges are designed to meet stringent safety standards and regulatory requirements. These gauges are built to withstand harsh conditions, including extreme temperatures, vibrations, and exposure to corrosive substances. ODM’s expertise allows manufacturers to integrate advanced technologies into their products, leading to greater accuracy and reliability.

Design Features of ODM Railway Pressure Gauges

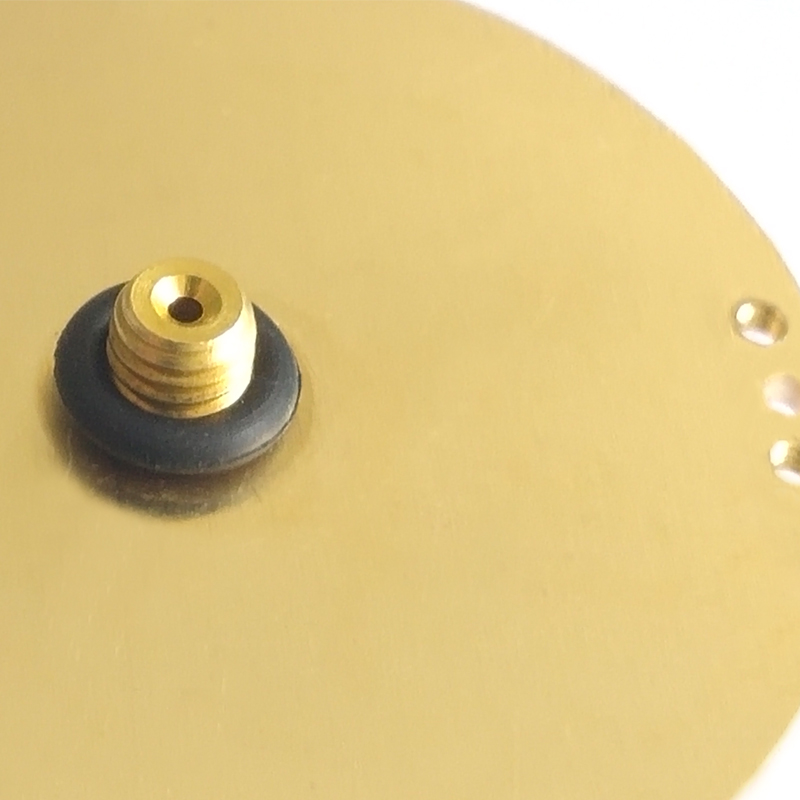

1. Durability ODM railway pressure gauges are constructed using high-quality materials resistant to wear and tear. Stainless steel, brass, and specialized polymers are often employed to ensure longevity and reliability in various environmental conditions.

2. Precision These gauges offer high precision, often with calibration standards that minimize errors. The accuracy of the readings is crucial for operators who rely on precise data to make real-time decisions.

3. User-Friendly Interfaces Modern ODM pressure gauges often feature digital displays and intuitive interfaces, making them easy to read and operate even in high-pressure situations. Some models may even integrate smart technology, allowing for remote monitoring and data logging.

odm railway pressure gauge

4. Safety Features Safety is paramount in railway operations. ODM pressure gauges are equipped with safety blow-off valves and fail-safe mechanisms that activate if pressure readings exceed predetermined thresholds. This feature helps prevent catastrophic failures.

Benefits of Utilizing ODM Railway Pressure Gauges

Investing in ODM railway pressure gauges offers several advantages

- Enhanced Safety By ensuring accurate pressure readings, these gauges contribute significantly to railway safety. Operators can monitor the performance of braking and other systems, reducing the risk of accidents.

- Operational Efficiency The ability to monitor pressure in real-time allows for timely maintenance and troubleshooting. This proactive approach reduces downtime and optimizes the performance of locomotives and other railway vehicles.

- Cost-Effectiveness Although the initial investment in high-quality ODM gauges may be higher, their durability and reliability lead to lower maintenance costs over time. A reduction in mechanical failures translates to significant cost savings for railway operators.

- Customization ODM pressure gauges can be tailor-made to meet specific operational requirements. This customization extends to size, range, and compatibility with existing systems, ensuring seamless integration into railway operations.

Conclusion

In conclusion, ODM railway pressure gauges are an indispensable component of railway operations. Their robust design, accuracy, and customizable features enhance safety and efficiency across the railway industry. As technology continues to evolve, the role of these pressure gauges will become increasingly critical, ensuring that railway systems operate smoothly and safely. The investment in high-quality ODM gauges is not just a matter of compliance, but a commitment to excellence in railway safety and performance.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025