Dec . 04, 2024 21:23 Back to list

ODM Metal Diaphragm Pressure Gauges for Precise Measurement Solutions and Applications

Understanding ODM Metal Diaphragm Type Pressure Gauges

Pressure gauges are essential instruments used in various industries to measure and monitor pressure levels in different systems. Among the various types of pressure gauges, ODM metal diaphragm type pressure gauges have gained considerable attention due to their accuracy, durability, and versatility. This article delves into the functionalities, benefits, and applications of ODM metal diaphragm type pressure gauges, providing a comprehensive understanding of their relevance in various sectors.

What is a Metal Diaphragm Pressure Gauge?

A metal diaphragm pressure gauge operates based on the principle of a flexible diaphragm that responds to pressure changes. When there is pressure acting on one side of the diaphragm, it deflects. This deflection is then converted into a readable measurement on the gauge. The diaphragm is typically made of high-quality stainless steel or other durable materials, which ensures resistance to corrosion and extreme environments. This design offers significant advantages over traditional Bourdon tube gauges, particularly in applications involving corrosive or high-viscosity fluids.

Key Features of ODM Metal Diaphragm Pressure Gauges

1. Accuracy and Precision ODM metal diaphragm pressure gauges are designed to provide accurate and reliable pressure readings. Their ability to respond quickly to pressure changes makes them suitable for applications where precision is critical.

2. Durability The robust construction of metal diaphragm gauges means they can withstand harsh environments. They are resistant to shocks, vibrations, and temperature fluctuations, making them ideal for challenging industrial settings.

3. Versatility These gauges can be used for a wide range of applications, including measuring the pressure of gases and liquids, particularly in chemical processing, oil and gas, and food industry applications. Their adaptability makes them a preferred choice in various sectors.

4. Low Maintenance Due to their simple design and the robustness of the materials used, ODM metal diaphragm type gauges require less maintenance compared to other types of pressure gauges. This feature minimizes downtime and operational costs.

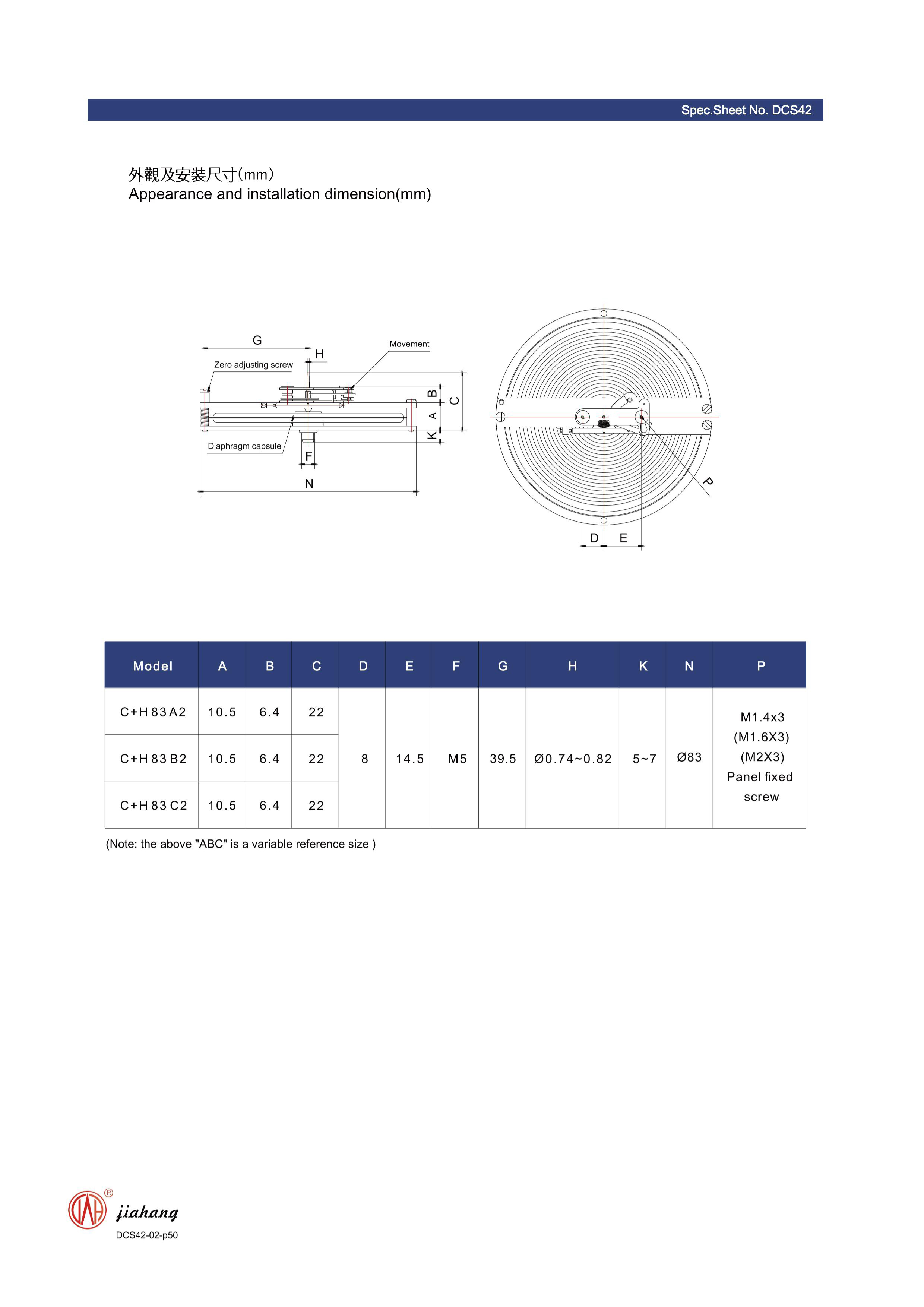

odm metal diaphragm type pressure gauges

Applications of ODM Metal Diaphragm Pressure Gauges

1. Chemical Processing In the chemical industry, the accurate monitoring of pressure is vital for safety and operational efficiency. ODM metal diaphragm gauges can handle aggressive chemicals and high-pressure environments, ensuring reliable performance in reactors and pipelines.

2. Oil and Gas In the oil and gas sector, these gauges are extensively used for monitoring pressure in drilling operations, pipeline transport, and refining processes. Their resistance to corrosive substances allows them to function effectively in challenging environments.

3. Food and Beverage Industry Quality and safety are paramount in food processing. ODM metal diaphragm pressure gauges help maintain optimal pressure in various processes, ensuring product quality and compliance with safety standards.

4. Pharmaceuticals In pharmaceutical manufacturing, maintaining proper pressure is crucial for ensuring product efficacy and safety. These gauges provide accurate readings essential for monitoring processes such as fermentation and sterile filtration.

Conclusion

ODM metal diaphragm type pressure gauges are invaluable tools in various industrial applications, providing precise measurement and maintaining safety and efficiency. Their robust design, durability, and versatility make them suitable for challenging environments, particularly in sectors like chemical processing, oil and gas, food and beverage, and pharmaceuticals. As industries continue to emphasize automation and process optimization, the demand for reliable pressure measurement instruments like ODM metal diaphragm gauges is likely to grow.

In summary, understanding the capabilities and applications of ODM metal diaphragm pressure gauges is essential for professionals in engineering, operations, and maintenance. Their role in ensuring safe and efficient operations cannot be overstated, making them a critical component in modern industrial processes. When selecting a pressure gauge for your applications, consider the operational conditions and specific requirements to ensure you choose the right instrument for optimal performance and reliability.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025