Oct . 31, 2024 13:29 Back to list

High-Precision Double Diaphragm Differential Pressure Gauge for Accurate Measurements

Understanding ODM Double Diaphragm Differential Pressure Gauge

In the realm of industrial measurement and control, the ODM double diaphragm differential pressure gauge stands out for its precision and reliability. This instrument is essential for monitoring pressure differences between two points in a system, making it invaluable across various applications, from manufacturing processes to chemical industries.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points. Unlike traditional gauges, which measure absolute pressure relative to atmospheric pressure, differential pressure gauges focus solely on the variance between two systems. This is crucial in systems where monitoring the flow, level, or filtration is vital.

The Role of the ODM Double Diaphragm Design

The double diaphragm design of the ODM gauge enhances its performance in several ways. It consists of two diaphragms that are separated by a specific distance and used to sense pressure from two separate inputs. This configuration provides several benefits

1. Increased Accuracy The dual diaphragm setup minimizes the influence of temperature fluctuations and other environmental factors, leading to more accurate readings. 2. Enhanced Durability The double diaphragm system offers superior resistance to corrosive environments, making it suitable for harsh chemical applications. The materials can be selected based on the specific fluids being measured, ensuring longevity and reliability.

3. Safety Mechanism In high-pressure applications, the double diaphragm acts as a safety barrier. If one diaphragm fails, the second remains intact, preventing accidental pressure loss and potential hazards.

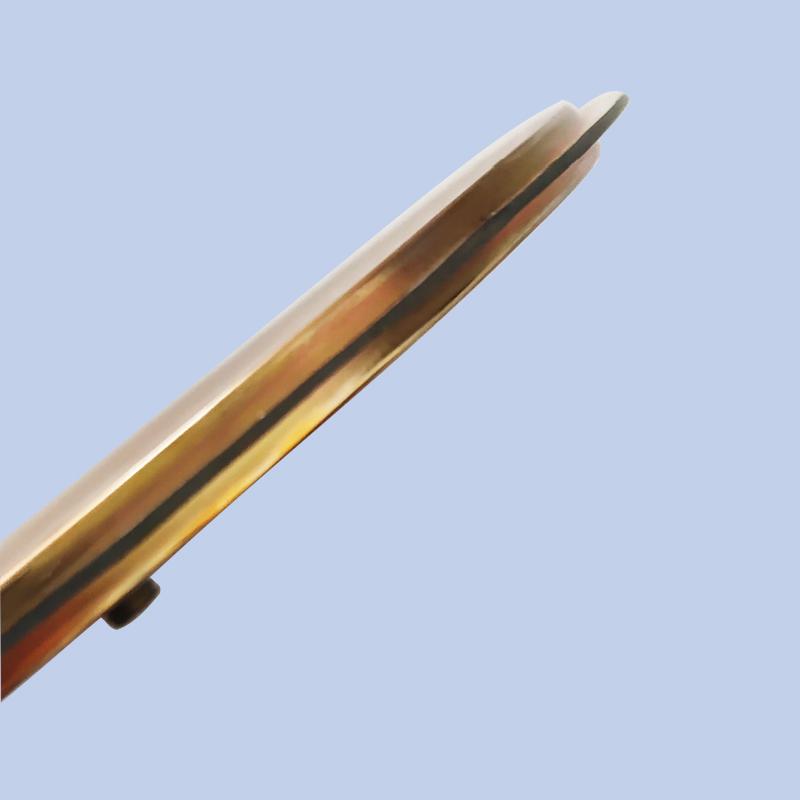

odm double diaphragm differential pressure gauge

Applications of ODM Double Diaphragm Differential Pressure Gauges

ODM double diaphragm differential pressure gauges have a broad range of applications. They are commonly used in

- Process Industries In chemical plants, these gauges help monitor the pressure drops across filters and meters, ensuring optimal flow and preventing equipment damage.

- Water and Waste Treatment They are employed to track pressure differences in treatment systems, allowing for efficient operation and maintenance of pumps and filtration systems.

- HVAC Systems In heating, ventilation, and air conditioning systems, they monitor pressure imbalances, which can indicate filter blocking or duct leaks.

Conclusion

The ODM double diaphragm differential pressure gauge plays a crucial role in the accuracy and safety of various industrial processes. Its unique design, emphasizing durability and precision, makes it a reliable choice for engineers and technicians seeking effective solutions for pressure measurement. As industries continue to evolve, the need for reliable and precise measurement tools like the ODM gauge will only grow, further highlighting its importance in modern engineering and technology. Whether in a chemical plant or an HVAC system, the significance of maintaining accurate pressure differentials cannot be overstated, underscoring the value of these sophisticated instruments.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025