Nov . 09, 2024 01:13 Back to list

Customized Differential Pressure Gauges for Enhanced Measurement Solutions in Various Applications

Understanding ODM Customized Differential Pressure Gauges

In the realm of industrial instrumentation, pressure measurement plays a crucial role in ensuring the efficiency and safety of various processes. Differential pressure gauges are essential devices for measuring the pressure difference between two points, making them pivotal in a variety of applications including HVAC systems, filtration processes, and fluid dynamics. Among the many options available in the market, ODM customized differential pressure gauges stand out due to their tailored features and functionalities.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the pressure building between two points within a system. This measurement is critical in applications where maintaining a specific pressure differential is necessary. For example, in HVAC systems, differential pressure gauges help monitor the difference between the pressure inside vents and the atmospheric pressure, aiding in ensuring proper airflow and system efficiency. In filtration systems, they indicate when filters need replacement by showing the pressure drop across them.

The Importance of Customization

While standard differential pressure gauges serve many purposes, the complexities of modern industries often require customization. ODM, which stands for Original Design Manufacturer, specializes in creating customized solutions tailored to the specific needs of a client's application. This customization can include variations in measurement ranges, display types, materials, and connection methods.

1. Tailored Measurement Ranges Different applications often encounter varying operational conditions. ODM manufacturers can design differential pressure gauges with custom measurement ranges, accommodating the specific pressure needs of a client’s system.

2. Display Options Visual representation of data is vital. Customized gauges can include specific types of displays, such as analog, digital, or even smart interfaces that offer data logging and remote monitoring capabilities.

3. Material Selection Depending on the environment where the gauge will be employed, the materials used can significantly affect performance and longevity. For instance, gauges used in corrosive environments require materials like stainless steel or special alloys, while those in clean environments could utilize more basic materials.

4. Connection Methods Every system has distinct requirements when it comes to connections. Customized gauges may be designed with various fitting types to ensure easy installation and maintenance without compromising on performance.

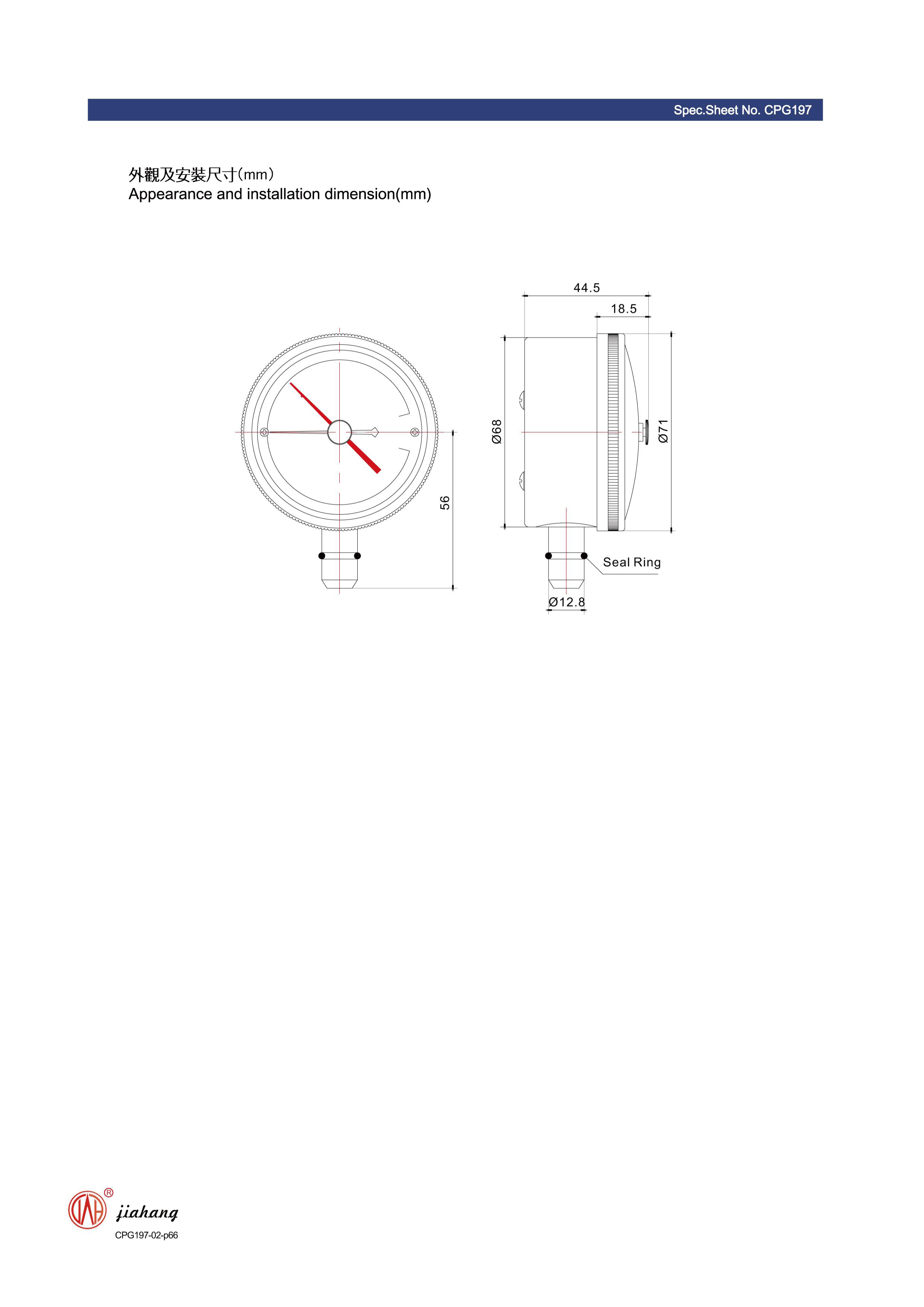

odm customized differential pressure gauge

5. Calibration and Accuracy Different industries often require specific calibration standards. ODM manufacturers can provide customized calibration levels to ensure that the gauges operate accurately within the desired environment.

Applications of Customized Differential Pressure Gauges

The application spectrum of customized differential pressure gauges is broad. Some of the key industries include

- Pharmaceuticals In pharmaceutical manufacturing, maintaining sterile environments is critical. Differential pressure gauges can monitor air pressure differentials in cleanrooms to ensure they meet regulatory standards.

- Oil and Gas The exploration and refining sectors require precise pressure measurements to ensure safe and efficient operations. Customized gauges can be designed to withstand the harsh conditions typical of these environments.

- Water Treatment Plants Monitoring the pressure of various filtration and treatment processes is essential for maintaining optimal performance. Customized gauges help in determining when systems require maintenance or replacement.

- HVAC In large commercial buildings, differential pressure gauges help in managing airflow, ensuring that heating and cooling systems operate efficiently, which can lead to significant energy savings.

Conclusion

In summary, ODM customized differential pressure gauges offer significant advantages over standard models, allowing industries to enhance the efficiency and reliability of their operations. By tailoring features to specific requirements, these specialized gauges not only ensure optimal performance but also contribute to the overall safety and regulatory compliance of critical processes. As industries continue to evolve, the role of customized instrumentation will become increasingly vital, making it essential for businesses to consider their unique needs when selecting pressure measurement solutions. In the world of differential pressure measurement, customization is not just an option—it is a necessity for achieving accuracy, efficiency, and reliability.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025