Oct . 16, 2024 05:53 Back to list

Understanding the ODM Barton Differential Pressure Gauge for Accurate Measurements and Applications

The ODM Barton differential pressure gauge is an essential instrument widely used in various industries to measure pressure differences between two points in a fluid system. This gauge serves critical roles in monitoring and controlling processes in fields such as oil and gas, pharmaceuticals, chemical processing, and water treatment. Understanding its functionality, applications, and advantages can help professionals in these industries optimize their operations.

A differential pressure gauge measures the difference in pressure between two input points, providing vital information about system performance. It works by employing a sensor that detects pressure variations from both ends of the gauge. This measurement allows operators to ascertain whether a system is functioning optimally or if there are anomalies leading to inefficiencies or potential failures. The ODM Barton differential pressure gauge is designed with precision and reliability, ensuring that the data it provides is accurate and usable for decision-making processes.

One significant application of the ODM Barton differential pressure gauge is in monitoring the performance of filters and strainers in fluid systems. Over time, particulate matter and debris can accumulate, causing pressure to increase on one side of the filter. By measuring the pressure differential, operators can determine when a filter needs cleaning or replacement, thereby preventing contamination and ensuring the system operates efficiently. Regular monitoring can extend the life of equipment and enhance overall operational safety.

Another critical use of this gauge is in HVAC (Heating, Ventilation, and Air Conditioning) systems. The differential pressure gauge helps maintain balanced airflow, which is crucial for energy efficiency and indoor air quality. By providing real-time data about pressure differentials within air ducts, operators can make informed decisions about airflow adjustments, leading to lower energy costs and enhanced comfort for building occupants.

odm barton differential pressure gauge

In the oil and gas industry, the ODM Barton differential pressure gauge plays a pivotal role in monitoring the performance of pipelines and pressure vessels. By tracking pressure differentials, professionals can detect leaks or blockages, mitigate risks, and enhance the safety of operations. Furthermore, accurate pressure readings can aid in optimizing pumping systems, ensuring that the right amount of fluid is being transported efficiently.

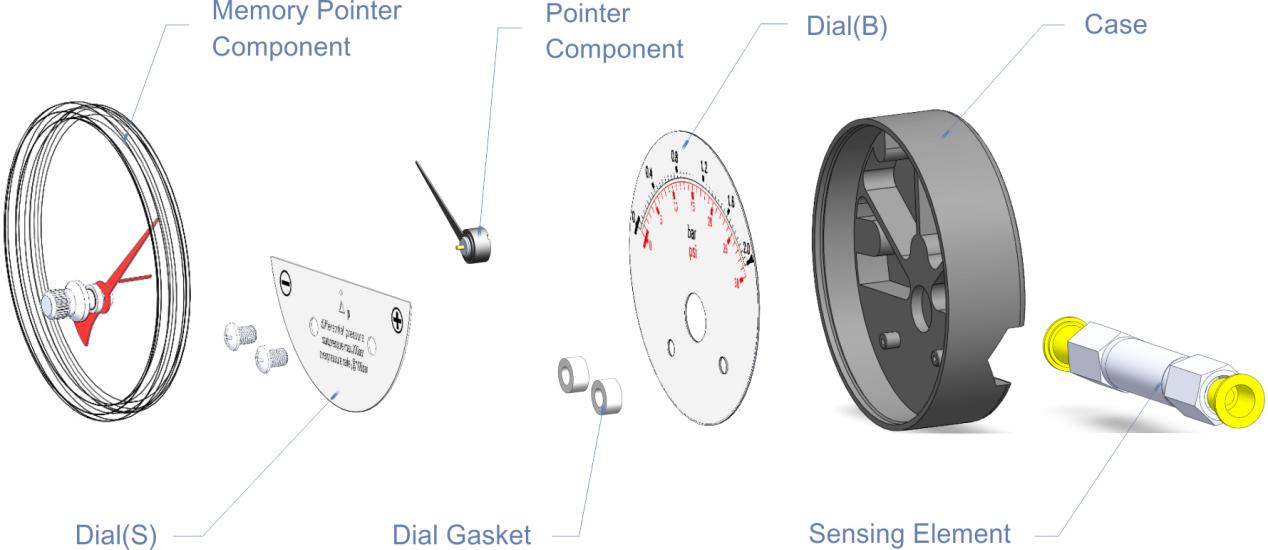

The design of the ODM Barton differential pressure gauge often incorporates features that enhance its durability and ease of use. Many models are equipped with clear, easy-to-read dials and scales, further facilitating quick assessments in high-pressure environments. Additionally, the construction materials are selected to withstand harsh conditions, balancing sensitivity with resilience.

Furthermore, advancements in technology have allowed the incorporation of digital interfaces and connectivity options into differential pressure gauges. This modernization enables remote monitoring, reducing the need for on-site inspections and allowing for real-time data analysis. Such innovations can lead to enhanced predictive maintenance strategies, ensuring that systems remain operational with minimal downtime.

In conclusion, the ODM Barton differential pressure gauge is a vital instrument for various industries, enabling users to monitor and manage pressure differences effectively. Its applications range from ensuring the efficiency of filtering systems to optimizing HVAC operations and enhancing safety in the oil and gas sector. By providing accurate and reliable pressure measurements, this gauge contributes to more efficient operations, longer equipment lifespan, and reduced risks in demanding environments. As industries continue to evolve, the importance of such precision instruments will only grow, highlighting the need for robust solutions in pressure management.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025