Aug . 30, 2024 15:04 Back to list

odm low pressure diaphragm pressure gauges

Understanding ODM Low Pressure Diaphragm Pressure Gauges

Low pressure measurement is crucial in many industrial and scientific applications, and among the various types of instruments designed for this purpose, ODM low pressure diaphragm pressure gauges stand out for their precision and reliability. These gauges are widely used in sectors such as pharmaceuticals, petrochemicals, HVAC (heating, ventilation, and air conditioning), and food processing, where accurate pressure readings are essential for maintaining safety and efficiency.

What is a Diaphragm Pressure Gauge?

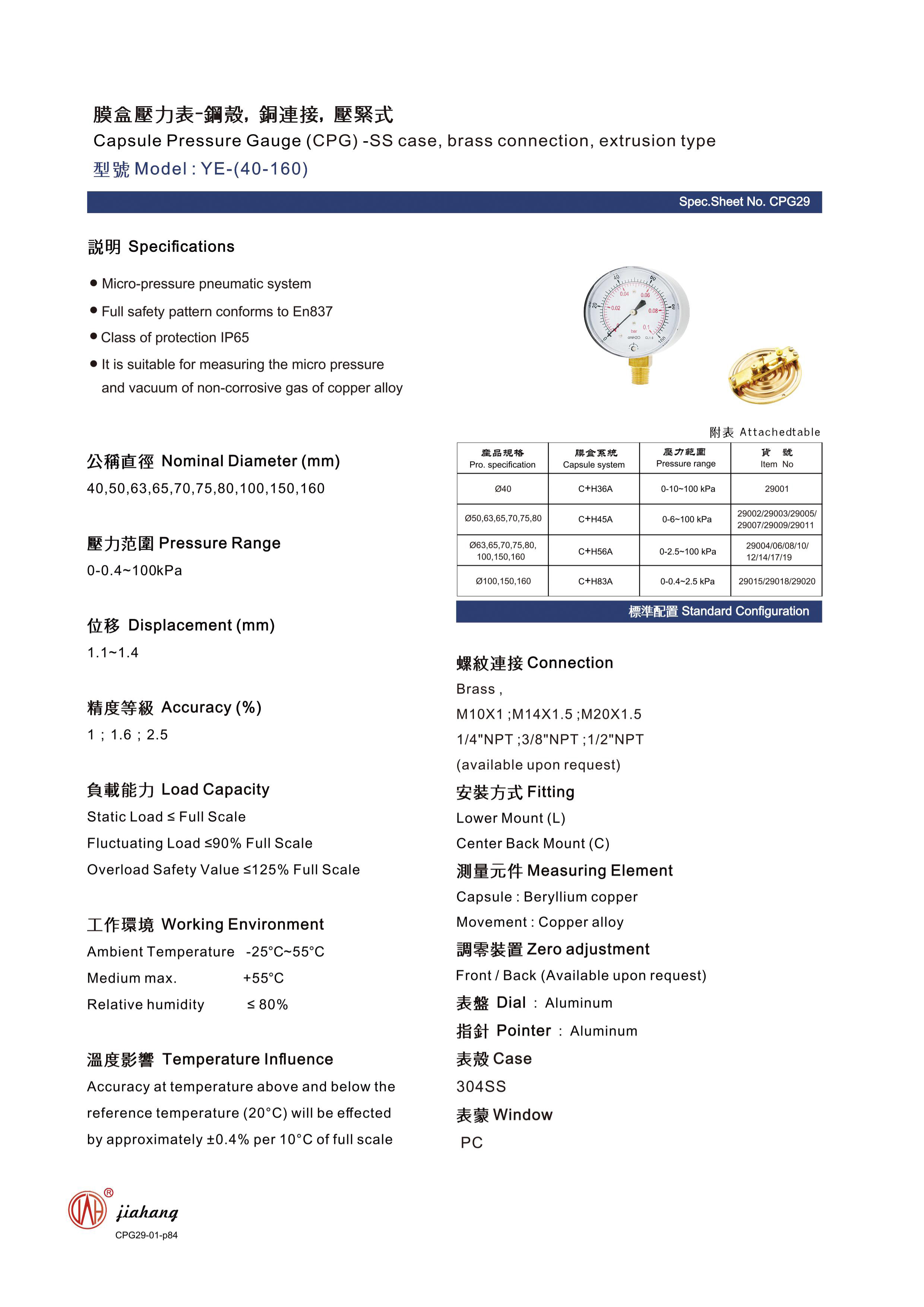

A diaphragm pressure gauge operates by using a flexible diaphragm to sense pressure changes. When pressure is applied to the medium (gas or liquid), it deforms the diaphragm, creating a displacement. This mechanical movement is then translated into a pressure reading via a series of levers and linkages connected to a calibrated needle on a dial.

The construction of the diaphragm is critical in determining the gauge’s sensitivity and range. ODM low pressure diaphragm gauges often feature materials such as stainless steel or specific elastomers, allowing them to handle corrosive environments while providing an accurate response to low pressure changes.

Characteristics of ODM Low Pressure Diaphragm Pressure Gauges

1. Sensitivity ODM gauges are designed specifically for low pressure applications, often measuring pressures in ranges as low as 0-30 inch of water column. Their sensitive diaphragm mechanism ensures that even the slightest changes in pressure can be detected and accurately displayed.

2. Durability Designed to withstand harsh conditions, ODM low pressure gauges are robust and reliable. The selection of durable materials ensures a long service life, reducing the need for frequent replacements.

3. Calibration and Accuracy Accurate readings are paramount in pressure measurement. ODM instruments undergo stringent calibration processes to ensure accuracy, making them trusted options in critical environments where precise pressure control is necessary.

odm low pressure diaphragm pressure gauges

4. Versatility These gauges can be utilized in a variety of applications, from monitoring boiler pressure in HVAC systems to measuring air filters in cleanrooms. Their adaptability means they can be incorporated into various systems seamlessly.

5. Easy to Read The dial display of ODM gauges is designed for clarity, with marked graduations that facilitate quick reading. This aspect is particularly important in operational environments where time efficiency is crucial.

6. Safety Features Many ODM diaphragm pressure gauges come equipped with safety features to prevent damage from sudden pressure surges or vacuum conditions. This not only protects the gauge but also ensures the safety of personnel.

Applications

ODM low pressure diaphragm pressure gauges find extensive use in multiple applications. In the pharmaceutical industry, they monitor processes where the control of low pressure is vital to ensure optimal conditions for sensitive reactions. In HVAC systems, they help in maintaining airflow and efficiency by accurately measuring pressure drops across filters.

In the food processing sector, these gauges assist in monitoring pressures in processing equipment to ensure food safety and quality. Their robust design and reliability make them indispensable tools across various industries.

Conclusion

In summary, ODM low pressure diaphragm pressure gauges play a crucial role in several industrial applications, providing accurate, reliable, and sensitive pressure measurements. Their durability, easy readability, and safety features make them an essential instrument for engineers and technicians seeking to ensure operational efficiency and safety. With the ever-increasing demand for precision in pressure monitoring, ODM gauges are poised to remain at the forefront of low pressure measurement technology.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025