Dec . 03, 2024 17:42 Back to list

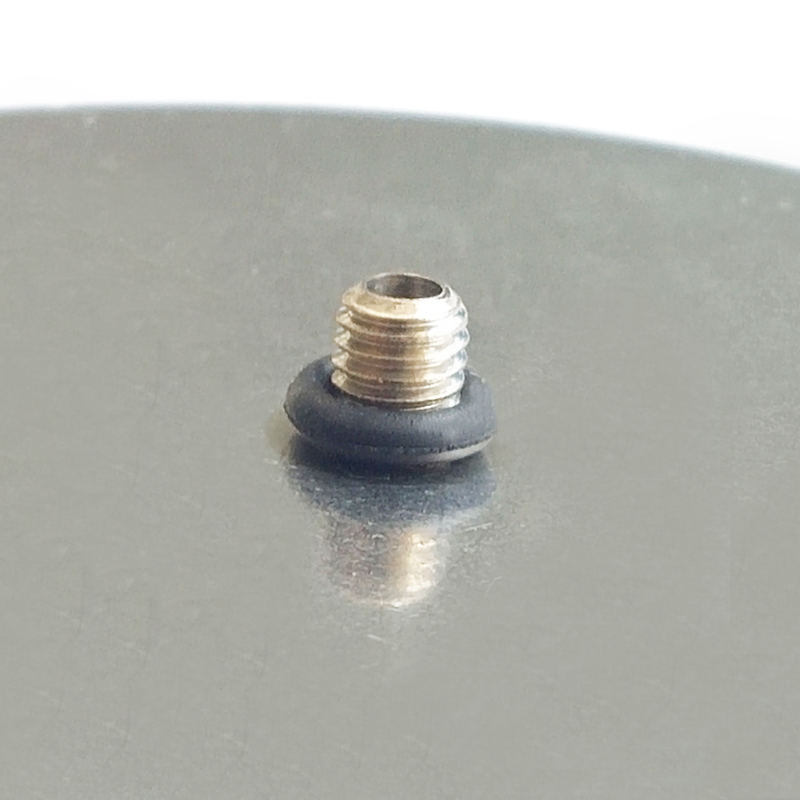

mini differential pressure gauge jah

Understanding Mini Differential Pressure Gauges JAH Series

In the world of precision measurement, differential pressure gauges serve a vital role across various industries, including HVAC systems, cleanrooms, and industrial processes. The JAH series of mini differential pressure gauges has garnered attention for its compact design and exceptional functionality. This article will explore the significance of these gauges, their applications, features, and benefits.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points in a system. This measurement is crucial for ensuring optimal performance, efficiency, and safety in various applications. Unlike standard pressure gauges that measure absolute pressure, differential gauges are used where pressure differences are more critical than absolute measurements.

The JAH Series A Miniature Marvel

The JAH series of mini differential pressure gauges is designed for environments where space is at a premium without sacrificing precision and reliability. Their compact size makes them ideal for use in small enclosures, complex machinery, and areas where larger gauges cannot fit. Despite their size, the JAH gauges maintain high accuracy and stability, ensuring dependable readings even under fluctuating conditions.

Key Features of the JAH Series

1. Compact Design One of the most significant advantages of the JAH series is its miniaturized design, enabling installation in tight spaces without compromising performance.

2. High Accuracy These gauges are engineered to provide precise readings, with minimal error margins. This accuracy is critical in applications where slight pressure differences can lead to performance inefficiencies.

3. Robust Materials JAH gauges are constructed from durable materials, making them resistant to environmental stressors such as temperature variations, humidity, and corrosive substances. This resilience extends their lifespan and reliability.

4. Easy Installation The gauges come with user-friendly interfaces and clear documentation, ensuring that technicians can install and operate them with minimal effort.

mini differential pressure gauge jah

5. Versatile Applications JAH series gauges can be applied in various settings, including filter monitoring, fan performance testing, and cleanroom pressure control, demonstrating their versatility across different industry sectors.

Applications of Mini Differential Pressure Gauges

The applications of the JAH series are vast and varied. In the HVAC industry, differential pressure gauges are crucial for monitoring air filtration systems. They help ensure that filters are not clogged, allowing for efficient airflow and preventing unnecessary energy consumption.

In pharmaceutical and semiconductor manufacturing, maintaining precise pressure differentials is vital. The cleanliness and integrity of these environments can significantly impact product quality and safety. JAH gauges play a critical role in monitoring cleanroom pressures to prevent contamination.

Additionally, these gauges are used in medical devices and laboratory settings, where they monitor fluid and gas pressures in sensitive processes. The accuracy and reliability of the JAH series ensure consistent performance and compliance with industry standards.

Benefits of Using Mini Differential Pressure Gauges

The adoption of mini differential pressure gauges like the JAH series comes with multiple benefits. Firstly, their compact size allows for greater flexibility in design and installation, catering to modern technological demands. Secondly, the accuracy of these instruments leads to better control and optimization of processes, ultimately improving operational efficiency.

Moreover, robust construction enhances the longevity of the gauges, reducing maintenance costs and the need for frequent replacements. This aspect is particularly advantageous in industries where uptime and reliability are paramount.

Conclusion

The JAH series mini differential pressure gauges exemplify innovation in measurement technology. Their combination of compact size, accuracy, and durability makes them a valuable asset in various applications, from HVAC systems to cleanrooms. As industries continue to prioritize efficiency and reliability, understanding and utilizing instruments like the JAH differential pressure gauge will be crucial for maintaining optimal operational standards. Whether you are an engineer, technician, or industry professional, keeping an eye on the latest advancements in measurement technology will undoubtedly benefit your operational processes.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025