Dec . 11, 2024 23:24 Back to list

micro differential pressure gauge factory

Understanding Micro Differential Pressure Gauge Factories

The production of micro differential pressure gauges is an essential aspect of various industries, including pharmaceuticals, biotechnology, and environmental monitoring. These precision instruments play a critical role in measuring slight differences in pressure between two points in a system. In this article, we will explore the significance of micro differential pressure gauges, their applications, and the manufacturing process involved in producing these sophisticated devices.

The Importance of Micro Differential Pressure Gauges

Micro differential pressure gauges are designed to measure small pressure differences with high accuracy. They are essential in applications where maintaining a specific pressure level is crucial, such as in cleanrooms, HVAC systems, and gas transfer systems. These gauges can detect minor fluctuations in pressure that could indicate system inefficiency or impending failures.

In cleanroom environments, for example, maintaining specific pressure differentials is vital to prevent contamination. A micro differential pressure gauge can help monitor and control the conditions necessary for safe environments, ensuring that processes meet stringent regulatory standards.

Applications of Micro Differential Pressure Gauges

1. Pharmaceuticals and Biotechnology In these sectors, product purity and consistency are paramount. Micro differential pressure gauges help monitor the pressure in sterile environments, ensuring that no unwanted contaminants enter the production process.

2. Environmental Monitoring These gauges are extensively used in controlling air quality and pollution levels. By monitoring pressure differences in various environments, they help ensure compliance with environmental regulations.

3. HVAC Systems In heating, ventilation, and air conditioning systems, pressure control is crucial for efficiency. Micro differential pressure gauges help ensure that systems are balanced and operating correctly.

4. Industrial Processes Many industrial processes require precise pressure monitoring to optimize performance and safety. Micro differential pressure gauges are vital in industries such as food processing and chemical manufacturing, where pressure differentials can affect product quality.

micro differential pressure gauge factory

Manufacturing Process of Micro Differential Pressure Gauges

The production of micro differential pressure gauges is a detailed and careful process that requires precision engineering and high-quality materials.

1. Design and Engineering The first step involves designing the gauge to meet specific application requirements. Engineers use advanced software to model and simulate the gauge’s response to various pressure conditions. This step ensures that the final product will meet performance criteria and reliability standards.

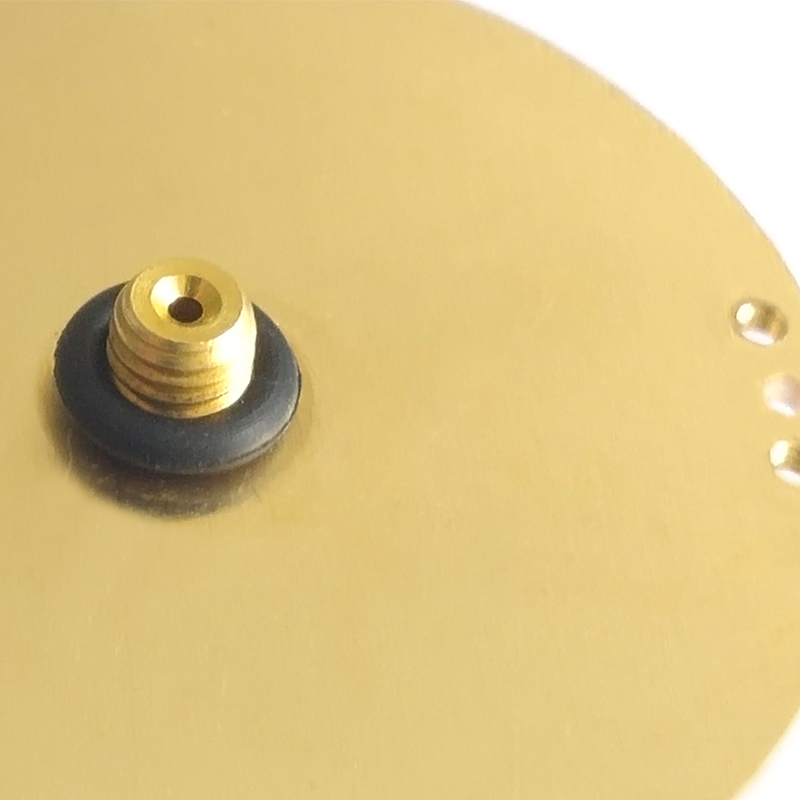

2. Material Selection The materials used in manufacturing micro differential pressure gauges must withstand various environmental conditions without compromising accuracy. Common materials include stainless steel, brass, and high-quality plastics.

3. Manufacturing Techniques Advanced manufacturing techniques, such as CNC machining, ensure that the components are made with precision. Each part of the gauge, from the diaphragm to the housing, is crafted to tight tolerances to ensure accuracy and durability.

4. Assembly After manufacturing the components, they are carefully assembled in a clean environment to prevent contamination. The assembly process involves integrating sensors, circuit boards, and other components, ensuring that they work harmoniously.

5. Calibration and Testing Once assembled, the gauges undergo rigorous testing and calibration. This step is crucial for ensuring accuracy, as even minor deviations can lead to significant errors in measurements. Testing might involve simulating various pressure conditions to ensure the gauge responds correctly.

6. Quality Control Finally, quality control processes verify that each gauge meets industry standards and customer specifications. This includes visual inspections, functional tests, and performance evaluations.

Conclusion

Micro differential pressure gauges are vital instruments in various industries, and their manufacturing demands precision and expertise. From ensuring pharmaceutical safety to optimizing HVAC efficiency, these gauges play an essential role in maintaining the integrity of various systems. As technology advances and industries evolve, the demand for high-quality micro differential pressure gauges will continue to grow, underscoring the importance of factories dedicated to their production. By understanding the production process and applications, stakeholders can appreciate the significance of these precision instruments in today’s technology-driven world.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025