Dec . 18, 2024 12:01 Back to list

medical oxygen pressure gauge factory

Understanding Medical Oxygen Pressure Gauges An Insight into Manufacturing

Medical oxygen pressure gauges play a crucial role in healthcare settings, ensuring the safe and efficient delivery of oxygen to patients in need. These devices are integral to various medical applications, from hospitals and clinics to home care environments. As the demand for medical oxygen continues to grow, so does the need for reliable pressure gauges. In this article, we will explore the manufacturing process of medical oxygen pressure gauges, their importance in healthcare, and future trends in this sector.

The Role of Medical Oxygen Pressure Gauges

Medical oxygen pressure gauges are instruments that measure the pressure of oxygen within a gas cylinder. They provide vital information regarding the amount of oxygen available for patient use. Accurate readings are essential, as they help healthcare professionals determine when a gas cylinder needs to be refilled, ensuring that patients receive a continuous supply of oxygen. Furthermore, these gauges are designed to function in a high-pressure environment, making them critical components of various respiratory therapies.

The Manufacturing Process

The production of medical oxygen pressure gauges involves several meticulous steps to ensure that the end product meets stringent safety and quality standards.

1. Design and Prototyping The initial phase involves the design of the pressure gauge, which includes selection of materials, dimensions, and functionalities. Designers must consider factors such as durability, accuracy, and compatibility with various oxygen sources. Prototypes are created and rigorously tested to refine the design before moving into full-scale production.

2. Material Selection High-quality materials are essential for the manufacture of pressure gauges, particularly in medical applications. Commonly used materials include brass, stainless steel, and certain plastics that are resistant to corrosion. These materials not only need to withstand high pressure but also should not react adversely with oxygen or other gases.

3. Machining Once the design is finalized, the components are produced through precision machining. This process may involve turning, milling, and drilling to create parts such as the gauge body, diaphragm, and connecting fittings. Advanced computer numerical control (CNC) machines are often employed to ensure high accuracy in the dimensions of each component.

medical oxygen pressure gauge factory

4. Assembly After machining, components are assembled to create the final product. Careful attention is paid to ensure that seals and joints are secure to prevent any gas leakage. This stage may involve the use of specialized tools and fixtures to achieve the right level of compression and alignment.

5. Testing and Calibration Each pressure gauge undergoes rigorous testing to verify its functionality and accuracy. Calibration is an essential part of this process, ensuring that the gauge readings correspond accurately to known pressure standards. Additionally, gauges are tested for durability and resistance to extreme conditions, such as temperature variations.

6. Quality Control Quality assurance teams perform final inspections to ensure each gauge meets industry regulations and standards such as ISO and FDA requirements. This step is vital to guarantee that the devices are safe for medical use and reliable in performance.

Future Trends

As technology advances, the manufacturing of medical oxygen pressure gauges is evolving. Innovations like digital pressure gauges are becoming more common, offering enhanced reading accuracy and ease of use. Furthermore, connectivity features such as Bluetooth may provide real-time monitoring capabilities, allowing healthcare providers to track oxygen levels remotely.

The rising trend toward home healthcare solutions is also influencing the design and functionality of medical oxygen pressure gauges, making them more user-friendly for patients and caregivers alike.

Conclusion

Medical oxygen pressure gauges are fundamental tools that ensure the safe and effective delivery of oxygen to patients across various healthcare environments. The meticulous manufacturing process behind these devices guarantees their reliability and accuracy, essential for patient safety. As healthcare continues to embrace technology and innovation, the evolution of medical oxygen pressure gauges will undoubtedly play a significant role in improving patient care in the future.

-

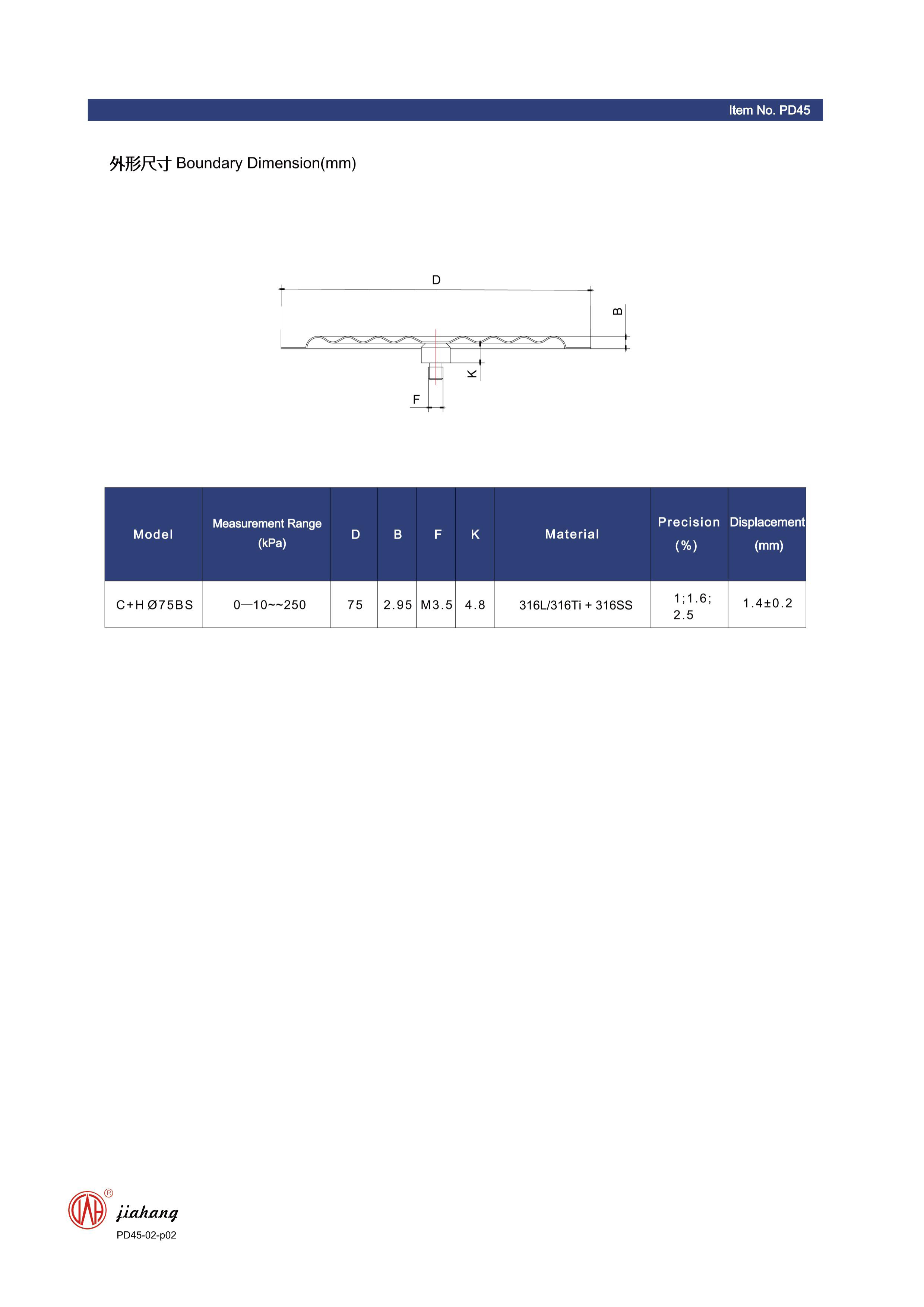

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025