Dec . 03, 2024 21:51 Back to list

Factory Production of Mechanical Differential Pressure Gauges for Accurate Measurement Solutions

Understanding Mechanical Differential Pressure Gauges A Comprehensive Overview

Mechanical differential pressure gauges are invaluable instruments widely used in various industrial applications to measure the pressure difference between two points in a system. This measurement is critical in fields such as HVAC, water treatment, and chemical processing, where maintaining optimal pressure levels is essential for efficiency and safety.

What is a Mechanical Differential Pressure Gauge?

A mechanical differential pressure gauge consists of two pressure inlets and a mechanical sensing element, typically a flexible diaphragm or bourdon tube. The gauge measures the difference in pressure between these two inlets, providing a direct reading on a dial or display. This type of gauge operates based on mechanical principles, requiring no external power source, which makes it a reliable option in environments where electrical devices may fail or pose safety hazards.

Working Principle

The working principle of mechanical differential pressure gauges involves the deflection of elastic elements in response to pressure changes. When pressure is applied to one inlet, the sensing element deflects accordingly. The difference in deflection between the two pressure inlets corresponds to the differential pressure, which is then transmitted to a pointer connected to the measuring element. The needle moves along a calibrated dial, providing a clear and immediate visual indication of the pressure difference.

Types of Mechanical Differential Pressure Gauges

There are several types of mechanical differential pressure gauges, each designed for specific applications

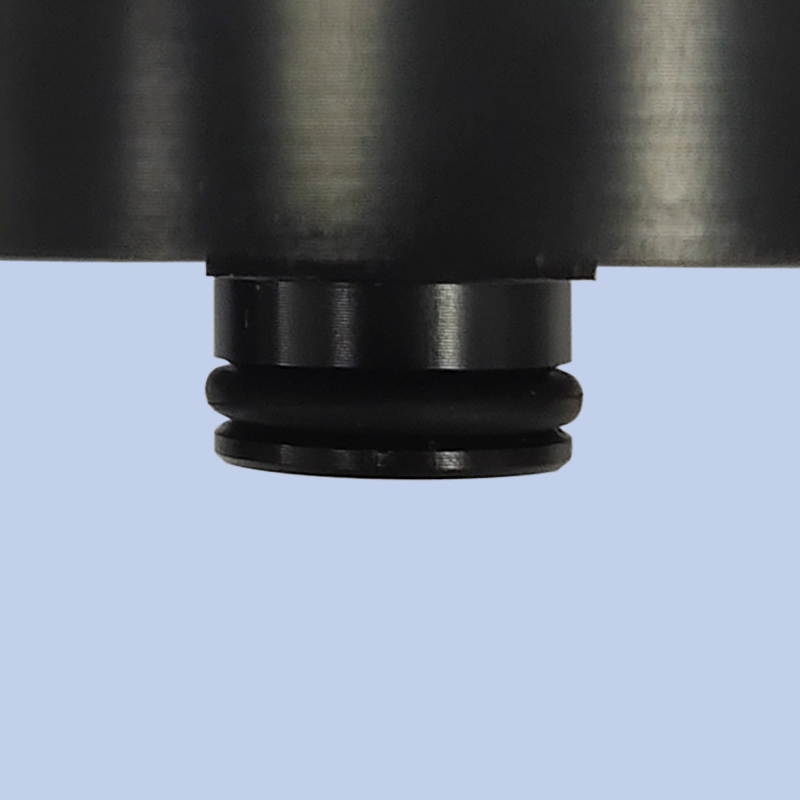

1. Diaphragm Gauges These utilize a diaphragm as the sensing element, which flexes in response to pressure changes. They are ideal for measuring low differential pressures in clean gas or liquid applications.

2. Bourdon Tube Gauges These gauges use a coiled tube that straightens out when internal pressure changes. They are commonly used for higher pressure differentials and are praised for their durability.

3. Capsule Gauges These employ two diaphragm-like capsules that expand or contract to measure pressure differences. They are highly sensitive and suited for very low differential pressures.

Applications

mechanical differential pressure gauge factory

Mechanical differential pressure gauges find numerous applications across various industries

- HVAC Systems In heating, ventilation, and air conditioning systems, these gauges monitor air or fluid pressure differences to ensure effective system operation. They help identify blockages or leaks in ducts, filters, and coils, which can impact system efficiency.

- Water Treatment In water treatment facilities, differential pressure gauges are essential for monitoring pressure drop across filters and membranes. A significant pressure change can signal the need for maintenance or replacement, ensuring the system operates efficiently.

- Chemical Processing In chemical plants, these gauges are critical for monitoring process conditions and ensuring safe operating procedures. They help maintain the necessary pressure levels in reactors and pipelines, contributing to the safety and efficiency of the production process.

Advantages of Mechanical Differential Pressure Gauges

1. Reliability Mechanical gauges are robust and can operate in harsh environments without the need for electrical components, making them less susceptible to failure.

2. Ease of Use The straightforward design allows for easy installation and maintenance, reducing downtime and operational costs.

3. Accuracy High-quality mechanical differential pressure gauges provide accurate readings, essential for effective monitoring and control in industrial processes.

4. Cost-Effectiveness Compared to electronic devices, mechanical gauges are generally less expensive, both in initial purchase and maintenance costs.

Conclusion

Mechanical differential pressure gauges are vital tools for industries requiring precise pressure measurements. Their reliable operation, simplicity, and cost-effectiveness make them an excellent choice for monitoring and maintaining process conditions. As technology advances, the basic principles remain relevant, ensuring that these gauges continue to play a crucial role in industrial applications. Understanding their functionality and appropriate applications can significantly enhance operational efficiency, safety, and performance in various sectors. Whether in HVAC, water treatment, or chemical processing, the importance of accurately measuring differential pressure cannot be overstated, solidifying the role of mechanical differential pressure gauges in modern industry.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025