Aug . 14, 2024 03:29 Back to list

Manufacturers of Differential Pressure Gauges for Industrial Applications and Custom Solutions

Understanding Differential Pressure Gauge Manufacturers and Their Factories

In the world of measurement and instrumentation, differential pressure gauges play a critical role in various industries. These devices are specifically designed to measure the difference in pressure between two points, making them indispensable in applications that require precise monitoring of fluid dynamics. As industries continually evolve, the demand for high-quality differential pressure gauges has led to the emergence of numerous manufacturers specializing in the production of these instruments.

The Importance of Differential Pressure Gauges

Differential pressure gauges are widely used in sectors such as oil and gas, chemical processing, pharmaceuticals, and wastewater management. They are essential for monitoring processes such as filtration, level measurement, and flow monitoring. By providing real-time data, these gauges help in maintaining safety standards, optimizing performance, and ensuring quality control.

Key Features of Differential Pressure Gauges

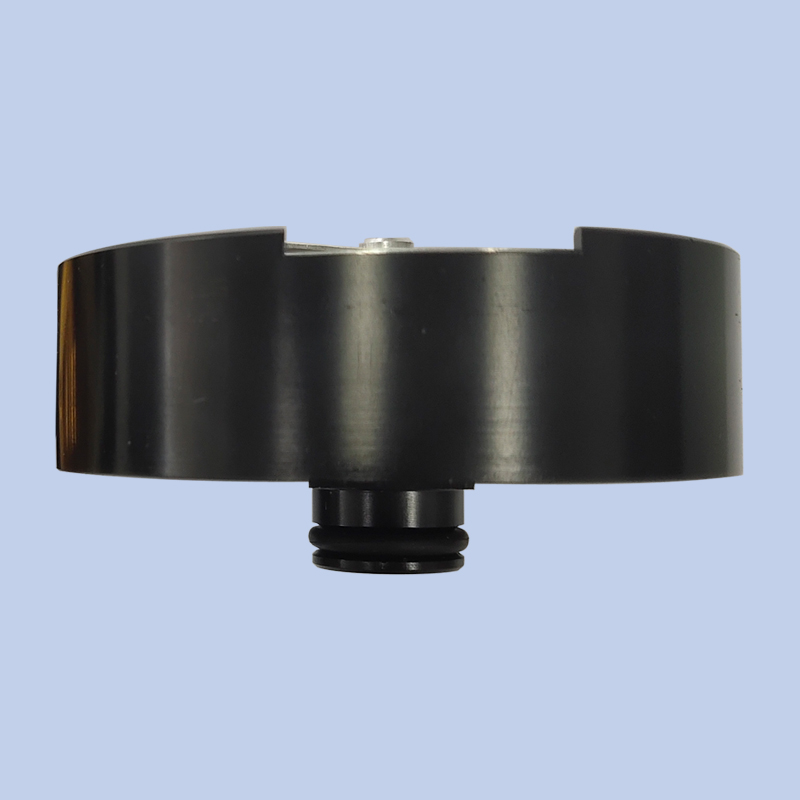

A typical differential pressure gauge consists of a sensing element, usually a diaphragm or a tube, that responds to pressure changes. The readings are displayed on a dial or a digital interface, translating mechanical movements into understandable data for operators. Manufacturers focus on several critical features when designing these gauges, including accuracy, reliability, and resistance to environmental factors such as temperature fluctuations and corrosive substances.

Choosing a Differential Pressure Gauge Manufacturer

When selecting a manufacturer for differential pressure gauges, several factors come into play. Quality assurance is paramount. Reputable manufacturers adopt stringent testing protocols to ensure their products meet industry standards such as ISO 9001. It is also crucial to consider the range of gauges offered. Reliable manufacturers typically provide a variety of models, catering to different application needs.

In addition to product quality, customer support and service are vital components of a successful partnership with a manufacturer. Leading companies invest in providing comprehensive pre-sales and post-sales support, ensuring that clients receive proper guidance and assistance. This can include installation help, calibration services, and ongoing maintenance.

differential pressure gauge manufacturers factory

Innovations in Manufacturing Practices

The manufacturing of differential pressure gauges has seen advancements due to emerging technologies. Factories are increasingly adopting automation and advanced manufacturing techniques to improve precision and reduce production costs. The use of computer-aided design (CAD) software allows manufacturers to design more intricate and effective gauge components, optimizing performance.

Additionally, many modern factories focus on sustainable practices. This includes minimizing waste during production, utilizing recyclable materials, and employing energy-efficient processes. As industries become more aware of their environmental impact, manufacturers are responding by adapting their practices to promote sustainability.

Global Market Trends

The global market for differential pressure gauges is expected to witness significant growth in the coming years, driven by the increasing demand for accurate measurement solutions across various industries. Manufacturers are expanding their operations internationally to meet this demand, often establishing factories in regions where production costs are lower, thus providing competitive pricing to customers.

The rise of the Internet of Things (IoT) has also impacted the differential pressure gauge market. Manufacturers are now integrating digital technologies into their products, allowing for remote monitoring and data analytics. This trend not only enhances the functionality of differential pressure gauges but also opens new avenues for manufacturers to explore advanced features and applications.

Conclusion

In summary, the role of differential pressure gauge manufacturers and their factories is vital in the broader landscape of industrial instrumentation. As industries demand more precise and reliable measurement tools, manufacturers must continually innovate and adapt to changing market conditions. Quality, customer support, and sustainability will remain key pillars for success, as manufacturers strive to meet the evolving needs of their clients. The future looks promising for differential pressure gauges, poised to play an integral role in a variety of applications worldwide.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025