Oct . 06, 2024 05:10 Back to list

low pressure differential pressure gauge quotes

Understanding Low Pressure Differential Pressure Gauges A Comprehensive Overview

Low pressure differential pressure gauges are essential instruments used across various industries to measure the difference in pressure between two points. These gauges provide critical data that helps monitor and control processes, ensuring safety and efficiency in operations.

Differential pressure is the difference in pressure between two points in a system, often measured in applications involving filters, pumps, and pipelines. A low pressure differential pressure gauge is specifically designed to measure small pressure differences, typically below 5 psi. This level of precision is crucial in many applications, including HVAC systems, clean rooms, and pharmaceutical manufacturing, where even minor changes in pressure can indicate a potential issue.

One of the main advantages of low pressure differential pressure gauges is their ability to provide real-time data. This allows operators to respond promptly to changing conditions, reducing the risk of equipment failure or operational disruptions. They are used to monitor filter efficiency, detect leaks, and ensure consistent flow levels in various processes.

low pressure differential pressure gauge quotes

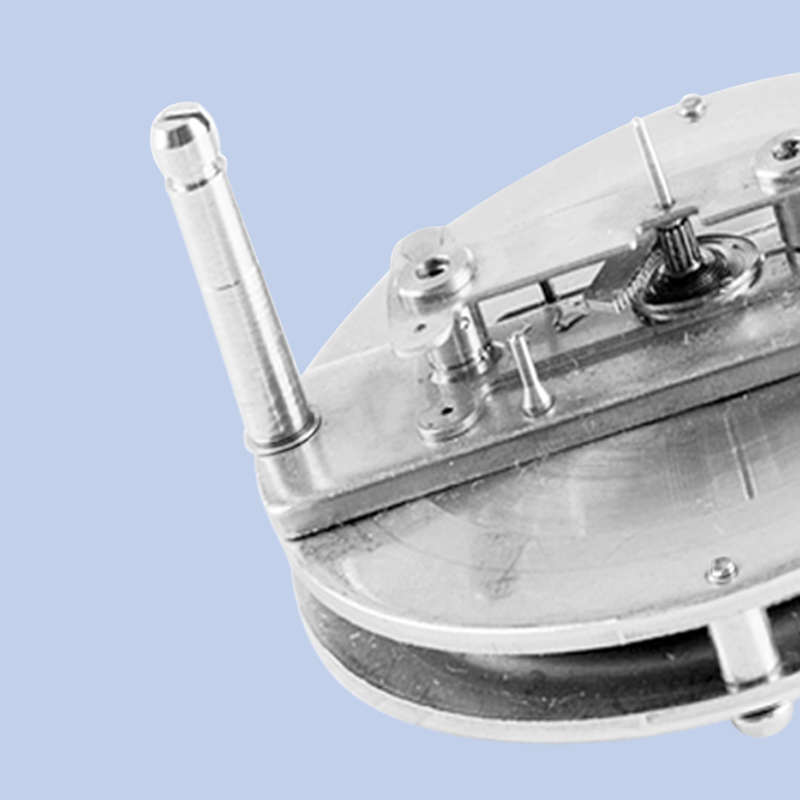

When selecting a low pressure differential pressure gauge, several factors should be considered. The range of pressure to be measured, accuracy, and the specific operating environment are critical. Different types of sensing technologies are available, including mechanical, capacitive, and piezoelectric sensors, each with its own advantages and ideal applications.

Additionally, the construction materials of the gauge must suit the process media. For instance, corrosive substances may require gauges made from specialized alloys or plastics to prevent damage and ensure long-term reliability.

Maintenance and calibration are also important aspects of using low pressure differential pressure gauges. Regular checks ensure that the instrument remains accurate and reliable, which is vital for processes that rely on precise pressure measurements.

In conclusion, low pressure differential pressure gauges play a vital role in many industrial applications. Their ability to measure small pressure differences accurately helps maintain system integrity, improve efficiency, and ensure safety. Investing in high-quality gauges and adhering to proper maintenance practices can lead to enhanced operational performance and prolonged equipment lifespan, making them an invaluable asset in modern industrial settings.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025