Nov . 25, 2024 08:44 Back to list

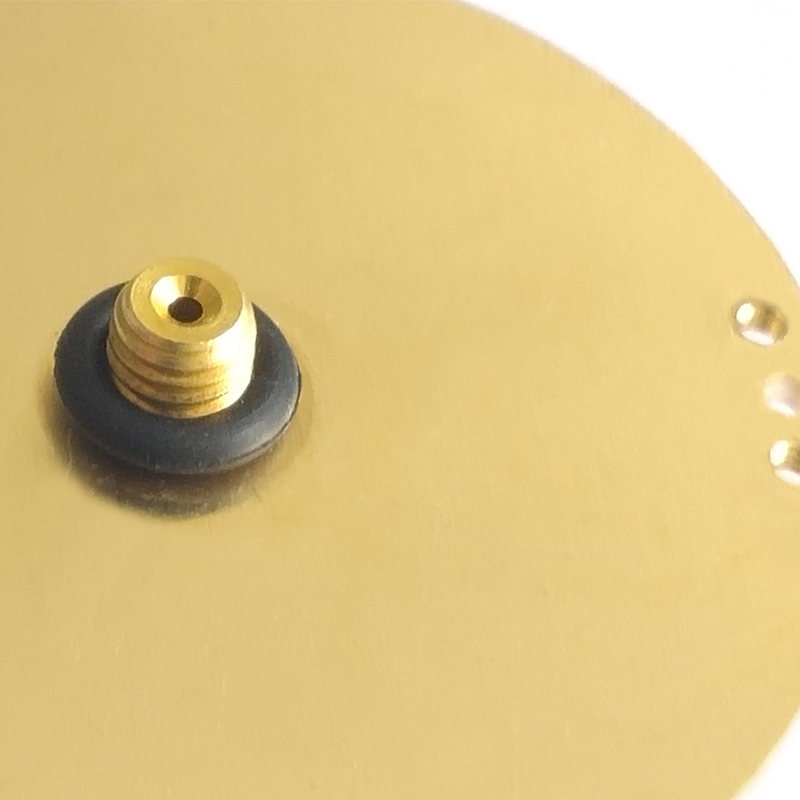

low pressure differential pressure gauge jah

Understanding Low Pressure Differential Pressure Gauges

In various industries, the measurement of pressure is crucial for ensuring safety, efficiency, and functionality. Among the various types of pressure gauges, low pressure differential pressure gauges stand out due to their ability to detect small differences in pressure between two points. This article explores the significance, working principles, applications, and advantages of low pressure differential pressure gauges.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device used to measure the difference in pressure between two points in a system. Unlike standard pressure gauges that measure absolute pressure, differential pressure gauges provide a comparative measurement. They are essential in applications where slight variations in pressure can lead to operational inefficiencies or safety hazards.

Importance of Low Pressure Measurement

Low pressure systems are common in industries such as HVAC (heating, ventilation, and air conditioning), pharmaceuticals, and food processing. In these sectors, the need to monitor low pressure differentials accurately is vital for maintaining optimal operations. For instance, in HVAC systems, maintaining the correct pressure differential ensures adequate airflow and prevents the buildup of harmful contaminants.

Working Principle of Low Pressure Differential Pressure Gauges

Low pressure differential gauges operate by measuring the pressure at two different points, typically using a diaphragm or mechanical spring mechanism. When there is a difference in pressure between these points, it causes the diaphragm to deform or the spring to compress, which in turn moves a needle or indicates the pressure differential on a calibrated scale. The design of these gauges allows them to provide accurate readings even with very small pressure differences, often as low as a few inches of water column (in WC).

Modern low pressure differential pressure gauges may also utilize digital sensors, providing enhanced accuracy and easier reading. These digital gauges often include features such as data logging, alarms, and connectivity to other monitoring systems, making them invaluable in automated industrial processes.

Applications of Low Pressure Differential Pressure Gauges

low pressure differential pressure gauge jah

1. HVAC Systems In HVAC applications, low pressure differential gauges are used to monitor air filters and ensure that airflow remains unobstructed. If pressure differences become too large, it may indicate that filters need changing or there is an obstruction in the ductwork.

2. Cleanrooms In pharmaceuticals or semiconductor manufacturing, maintaining a controlled environment is critical. Differential pressure gauges help monitor the integrity of cleanrooms by measuring pressure differentials between different areas, ensuring that contaminants do not infiltrate sensitive areas.

3. Fluid and Gas Measurement Low pressure differential gauges are employed to monitor flow rates in pipes by measuring the pressure drop across orifices or filters. This measurement is vital for maintaining efficient system operations and preventing malfunctions.

4. Water Treatment In water treatment facilities, these gauges monitor pressure differences to ensure that filtration systems are working properly and that pumps are operating efficiently.

Advantages of Using Low Pressure Differential Pressure Gauges

Low pressure differential pressure gauges offer several advantages. They enhance safety by providing early warning signs of pressure variations that may lead to equipment failure or hazardous situations. They also promote efficiency by ensuring that systems operate within their designed specifications, thus preventing energy losses and prolonging the lifespan of equipment.

Moreover, with advancements in technology, digital low pressure differential gauges offer improved accuracy and the ability to interface with other systems. This allows for better data analysis and real-time monitoring, which can lead to more informed decision-making and proactive maintenance strategies.

Conclusion

Low pressure differential pressure gauges are indispensable tools across various industries. By enabling precise measurements of minimal pressure differences, they help maintain operational integrity, improve safety, and optimize efficiency. As technology continues to advance, the capabilities and applications of these gauges will only expand, further solidifying their importance in modern industrial processes. Whether in HVAC systems, cleanrooms, or fluid dynamics, understanding and utilizing low pressure differential pressure gauges is essential for achieving superior operational performance.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025